#281

Navigating the New Indian Labour Codes: Salient Features and the Stark Realities of EHS Implementation

Posted on December 3, 2025

The ink is barely dry on India’s four groundbreaking Labour Codes, which sprang to life on November 21, 2025, consolidating 29 archaic laws into a streamlined framework aimed at modernizing the workforce. For those of us in Environment, Health, and Safety (EHS), the spotlight shines brightest on the Occupational Safety, Health and Working Conditions (OSHW) Code, 2020—a beacon promising enhanced worker protections, standardized safety norms, and a nod to emerging gig economies. These reforms, heralded by the Ministry of Labour and Employment, vow to align India with global standards, fostering social justice and sustainable workplaces. Yet, as we celebrate this legislative leap, a sobering question lingers: Will execution match ambition? In a nation where compliance often bends to convenience, the Codes risk becoming another chapter in our saga of good intentions gone awry. This post dissects the salient features driving EHS progress, while unflinchingly addressing the practical pitfalls and execution black holes that could derail them. Buckle up—it’s a 1,000-word reality check.

Salient Features: A Blueprint for Safer, Healthier Workplaces

At its core, the OSHW Code unifies 13 pre-existing laws—spanning factories, mines, docks, and construction—into a single, digestible 143-section behemoth, slashing paperwork from 868 rules to 175 and registrations from six to one. This “one-stop shop” for compliance is a game-changer for EHS professionals, who no longer juggle disparate mandates. Here’s what stands out:

First, universal safety mandates extend protections to all sectors, including hazardous processes and even single-worker setups. Establishments must form safety committees—mandatory for factories with 500+ workers, construction sites with 250+, and mines with 100+—to proactively identify risks, conduct audits, and recommend fixes. Third-party audits by government-empaneled experts add teeth, shifting from reactive inspections to preventive culture. A national Occupational Safety and Health Advisory Board, comprising tripartite stakeholders (government, employers, workers), will set uniform standards, creating a centralized database for unorganized and migrant workers to track exposures and interventions.

Health gets a major boost with free annual medical examinations for all employees, universalizing access to early detection and reducing absenteeism from occupational illnesses. Plantations, previously sidelined, now tap into Employees’ State Insurance (ESI) facilities. For women, the Code breaks barriers: Night shifts (7 PM to 6 AM) are permissible with consent and transport/safety provisions, and creches become compulsory for 50+ worker establishments, promoting gender equity in hazardous roles.

Working conditions see flexibility without forsaking safeguards. Standard hours cap at 48 per week (eight daily in a six-day setup), but states can tweak for models like 12-hour shifts over four days. Overtime—capped variably by states—pays double wages, with eligibility dropping for annual leave from 240 to 180 working days. Migrant workers, redefined broadly to include self-migrated interstate laborers, gain journey allowances, portable welfare benefits, and a 24/7 helpline—crucial in EHS hotspots like construction, where transient labor faces disproportionate risks.

Digital natives aren’t forgotten: Audio-visual workers (stunt performers, dubbing artists) and OTT/digital media pros fall under safety nets, mandating risk assessments for on-set hazards. Appointment letters are now non-negotiable, detailing wages, roles, and social security—formalizing gigs that often evade EHS oversight.

Penalties aim for deterrence: Non-compliance on general safety fetches ₹2-3 lakh fines (plus daily escalations), with 50% routed to victims in injury/death cases. Decriminalization swaps jail for fines in most offenses, allowing compounding (50-75% of penalty) after a 30-day improvement notice—easing “license raj” ghosts while funding a social security kitty from levies. All-India licenses (valid five years) and digitized registers (down from 84 to eight) digitize compliance, with inspector-cum-facilitators conducting randomized checks.

These features paint a progressive picture, potentially slashing India’s 48,000 annual occupational deaths (per ILO estimates) by embedding EHS into DNA. The other Codes complement this: Social Security expands ESI/PF to gig workers (aggregators contribute 1-2% turnover), while Wages standardizes definitions for overtime/gratuity calculations, indirectly bolstering health claims.

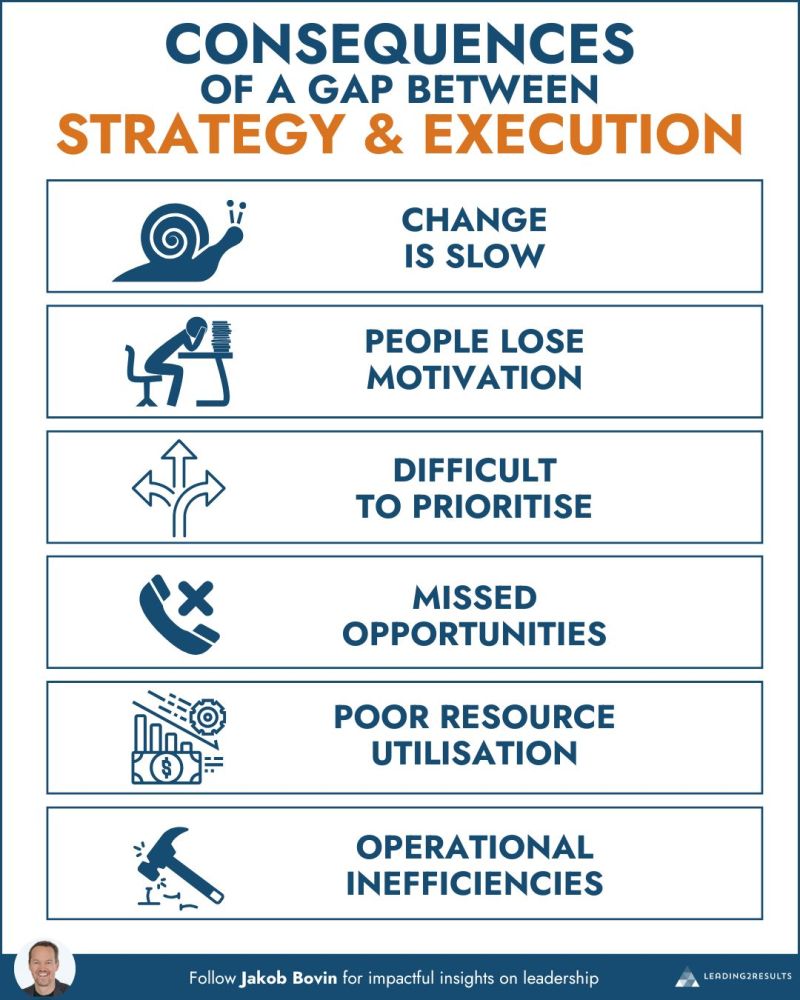

Practical Challenges: From Policy to Practice

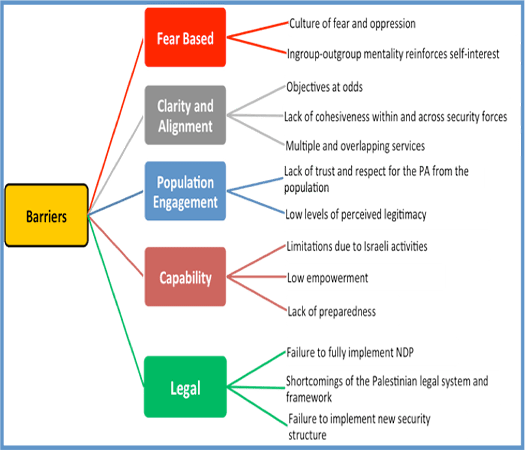

Implementation isn’t seamless. With rules still trickling in, businesses face a transitional haze—existing laws linger until state notifications, risking dual compliance in multi-state ops. SMEs, employing 90% of India’s informal workforce, grapple with resource crunches: Forming committees, auditing, and digitizing records demand tech upgrades many can’t afford. Awareness gaps loom large; a 2024 survey pegged only 40% of HR pros versed in draft rules—now, post-go-live, training rushes could overwhelm.

Contract labor thresholds rise (from 20 to 50 workers), but defining “core” activities sparks disputes—vital for EHS, as principals bear wage/safety liability. Migrant tracking via the national database sounds ideal, but interoperability with Aadhaar/PDS systems is untested, potentially excluding the very vulnerable. Overtime flexibility? States must notify limits, delaying uniform rollout and inviting exploitation in high-risk sectors like manufacturing.

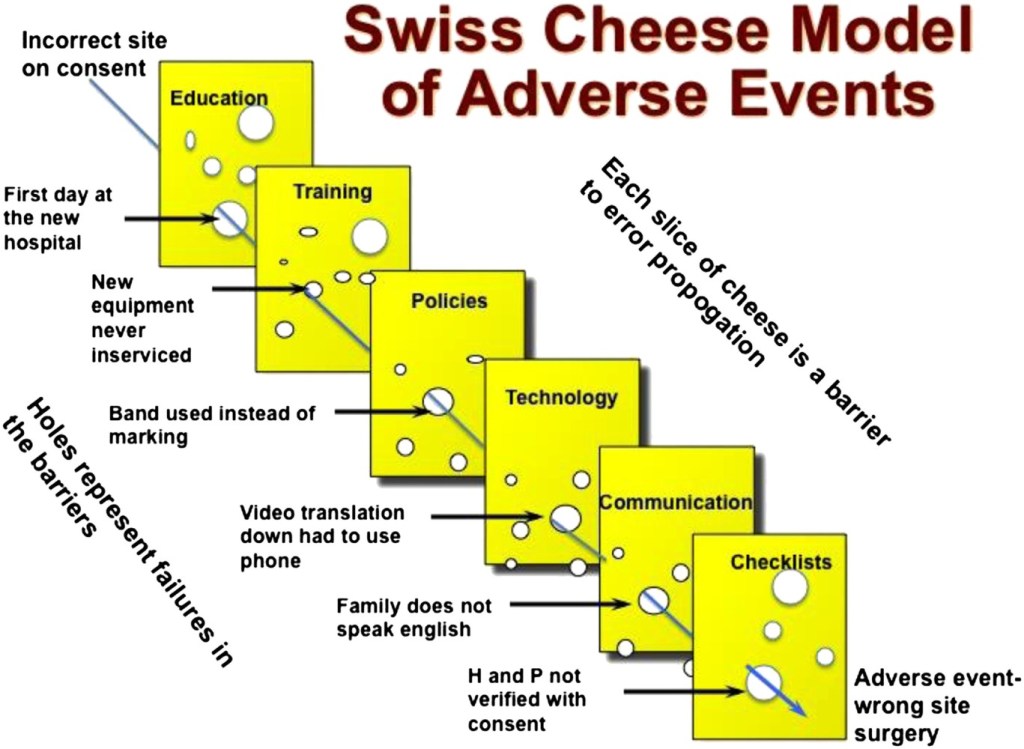

Enforcement hinges on 1,500-odd inspectors nationwide—woefully short for 63 million establishments. Randomized digital inspections help, but without capacity-building, they risk becoming tick-box exercises. For EHS, this means safety committees might exist on paper but falter in practice, especially in unorganized segments where 93% of workers toil.

Execution’s Achilles Heel: Apathy, Corruption, and the ‘Catch-Me-If-You-Can’ Mentality

Here’s the rub: India’s EHS execution has long been the missing link, and the Codes inherit this frailty. Penalties, while hiked, remain pittance for corporates—₹3 lakh for a fatality? That’s a rounding error against ₹100 crore turnovers, fueling the “don’t comply till caught” ethos. Bribery thrives in this vacuum; labor inspections, notorious for “harassment fees,” extract ₹10,000-50,000 per visit in informal sectors, per anecdotal reports, eroding voluntary adherence. Why invest in creches or check-ups when a palms-greased inspector looks away?

Courts compound the chaos, granting retrospective pardons for “deemed illegal” projects—environmentally rogue dams or factories get post-facto nods, normalizing violations. This judicial leniency, often politically tinted, shreds trust: Workers see safety as optional, owners as a cost-center. Voluntary compliance? A pipe dream when ownership feels illusory—gig platforms skirt contributions, migrants vanish into shadows. The Codes’ decriminalization, meant to facilitate, might embolden dodgers, as fines compound easily without jail’s sting.

In EHS, this translates to persistent horrors: Bhopal’s ghosts linger in unchecked chemical plants, construction collapses claim lives amid absent committees. Until penalties scale with revenue (say, 1-5% turnover) and anti-bribery tech (AI-monitored inspections) kicks in, execution will hobble.

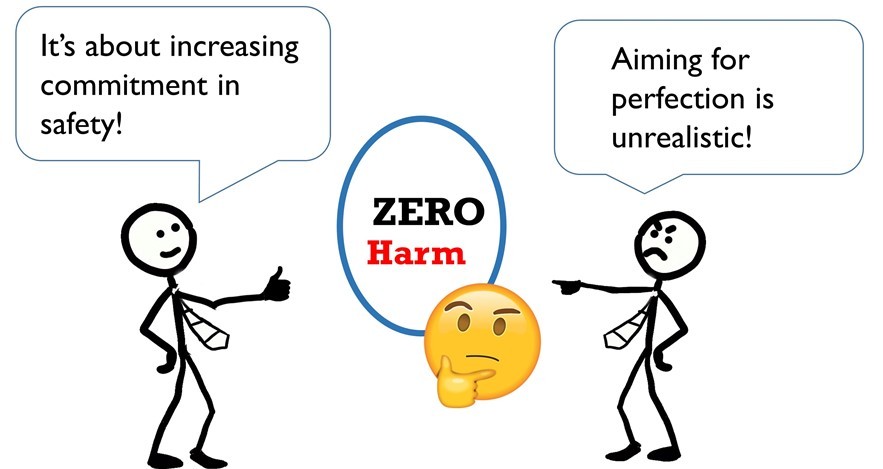

Charting a Compliant Future: Beyond Lip Service

The New Labour Codes offer EHS a rare renaissance—safer hours, healthier checks, equitable access. But without ruthless execution—beefed-up inspectors, whistleblower shields, and culturally ingrained accountability—they’re just words. Let’s demand more: Corporates, lead with ownership; regulators, enforce without fear or favor; workers, claim your rights. Only then can trust bloom, turning “compliance by coercion” into voluntary vigilance. India’s workforce deserves no less. What’s your take—ready to rewrite the script?

Karthik

3/12/25 1430 PST

Foster City CA.