This is a key aspect that must be a top priority for organisations in 2023 and beyond. Gone are the days when EHS (Environmental, Health and Safety) was seen as stand alone platform with its own resources and budget. Companies in the growth phase (more like 1990s, when Money was growing on trees) were willing to look the other way and complay with EHS to keep their places incident free and thus avoiding reputational risks. No longer!!

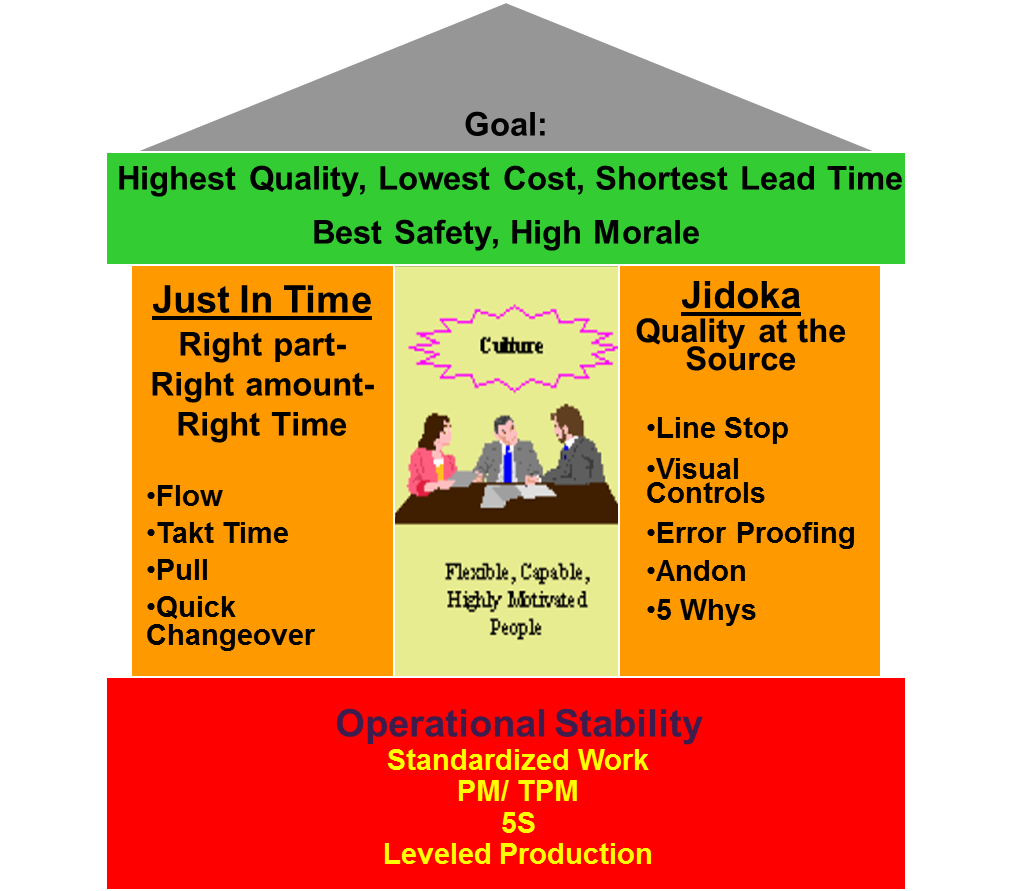

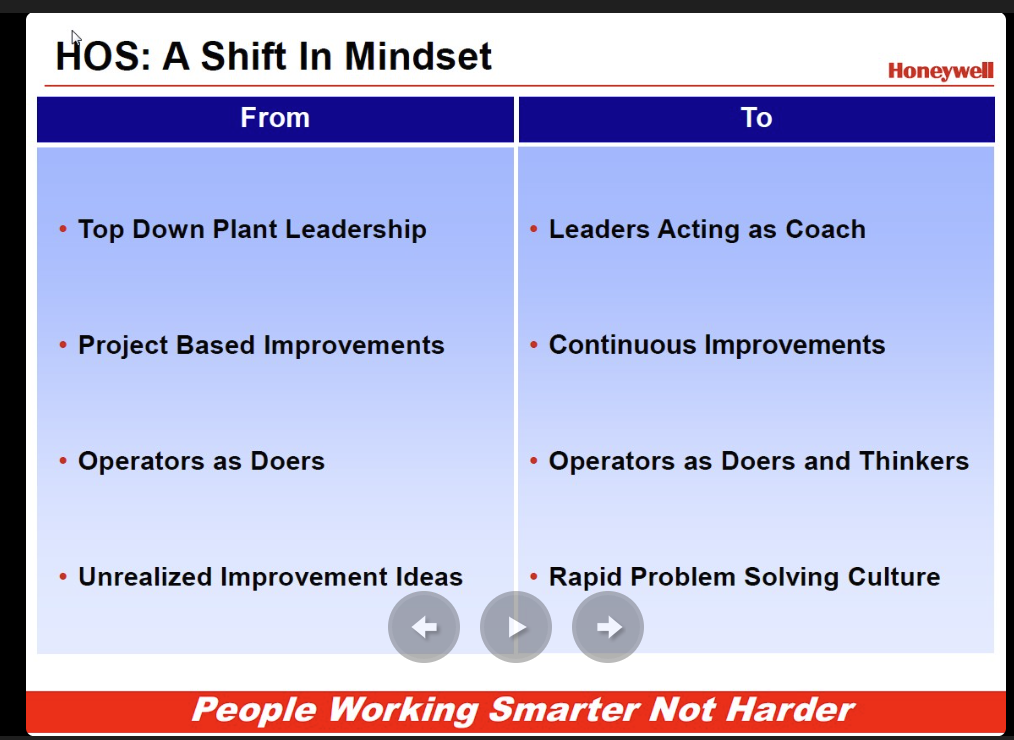

The 2008 financial crisis lead to deep efforts to cut budgets, and most affected were Training, Travel and non essential spending that are not directly linked to Regulatory compliance in EHS Domain. That prompted organisations to dwell deep to link business enablers like Quality, Safety (EHS) to the main oeprational platform and every aspect of spending/ budgets were linked to Operational excellence. The Business operating systems like “TOYOTA Production System” became the norm putting Safety, Quality, Productivity, Inventory, Delivery and Cost as enabler and company must work on an integrated approach to acheive this as part of business operating system.

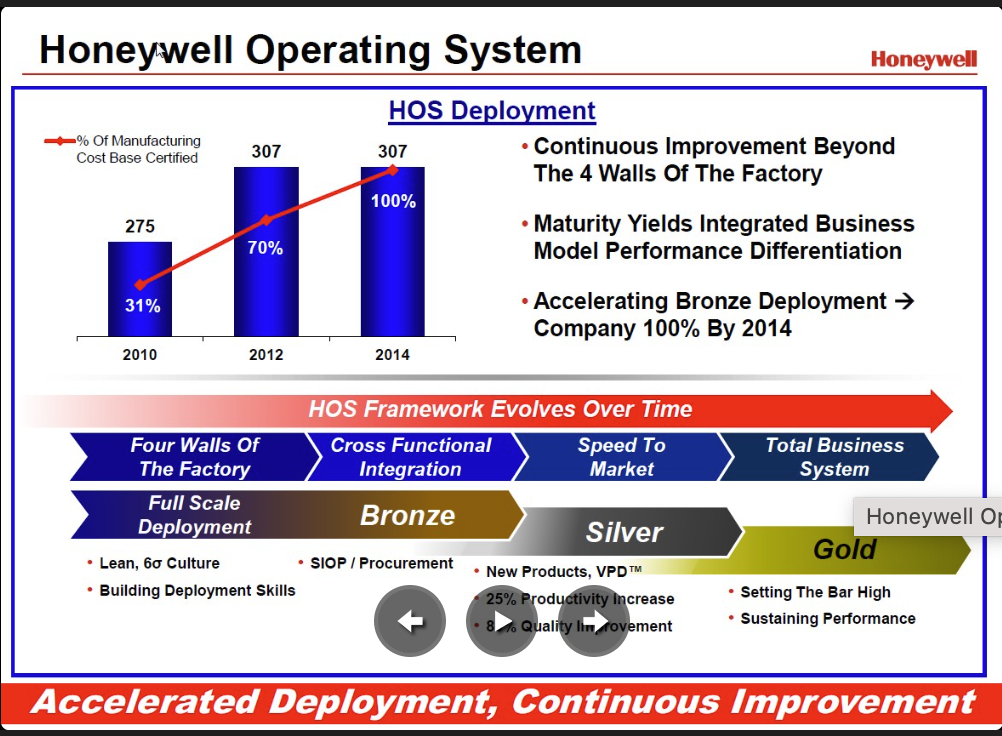

I was fortunate to work on a similar business system from 2006-12 at Honeywell, where EHS was integrated as a business enabler. The path to operational excellence was linked to EHS being one of the pillars and without a strong EHS pillar, excellence and thus achieving higher quality, productivity, delivery, lower delivery, and cost is not sustainable.

So how does Company go about it!

Integrating Environmental, Health, and Safety (EHS) improvements with operations aspects like Quality, productivity, and cost can be highly beneficial for an organization. Here are some strategies to play an active role in achieving these improvements:

- Establish Cross-Functional Collaboration: Work closely with operations, quality, Engineering, Projects and finance teams to create a collaborative approach to address EHS issues. Identify shared goals and potential synergies between EHS and other departments.

- Develop Key Performance Indicators (KPIs): Define measurable KPIs that link EHS performance to quality, productivity, and cost metrics. For example, track the number of safety incidents correlated with production output or the cost savings achieved through waste reduction initiatives.

- Risk Assessments and Root Cause Analysis: Conduct comprehensive risk assessments and root cause analyses to identify EHS-related risks that may impact quality, productivity, or cost. Addressing these root causes can prevent future incidents and improve operational efficiency. All EHS capital budgets must be linked to reduction # in Risk rating due to implementation of such measures.

- Continuous Improvement Initiatives: Encourage and participate in continuous improvement programs, such as Lean, Six Sigma, or Total Quality Management, and Total Preventive/ Predictive Maintenance, with a focus on integrating EHS improvements.

- Training and Awareness Programs: Promote EHS training and awareness programs among employees, emphasizing the link between EHS practices and overall operational performance. Educate employees about how safe and healthy work practices can positively impact productivity and product quality.

- Incorporate EHS into Standard Operating Procedures (SOPs): Ensure that EHS considerations are integrated into SOPs and work instructions. For example, include EHS checkpoints in production processes or equipment maintenance routines. Engage employees in SOP development, ask for their inputs. They would always come with a better soultions to issues as they are at work place 24*7.

- Incentive Programs: Support the development of incentive programs that recognize and reward employees for demonstrating exemplary EHS practices while contributing to quality and productivity targets.

- Life Cycle Assessment (LCA) and Environmental Impact Reduction: Analyze the environmental impact of products and processes through LCA to identify areas for improvement. This may lead to resource optimization, waste reduction, and cost savings. Look at any waste as a Non Productive resource and see how it can be minimized.

- Green Procurement Practices: Work with procurement teams to consider EHS criteria when selecting suppliers and materials. Environmentally friendly and sustainable practices may lead to cost savings and improved product quality. Engage Supply Chain in your EHS efforts to include suppliers and contractors. Collaborate with them to ensure their practices align with your organization’s EHS standards, which can help reduce risks and improve overall quality.

- Technology Adoption: Advocate for the implementation of advanced technologies and automation that can enhance safety, improve productivity, and reduce operational costs. Look for cycle time reduction that can eliminate time, space, materials etc.

- Benchmarking and Best Practices: Stay informed about industry best practices and benchmarks related to EHS, quality, productivity, and cost. Adopting successful strategies from other organizations can provide valuable insights.

- Communicate Success Stories: Share success stories and case studies that highlight the positive impact of EHS improvements on quality, productivity, and cost. Effective communication can foster support and engagement from all stakeholders.

By actively linking EHS improvements to operations aspects, you can drive positive change throughout the organization, create a safer and healthier work environment, improve product quality, enhance productivity, and reduce operational costs, leading to sustainable and responsible growth.

As can be seen such efforts can be extended to beyond 4 walls of factory in to supplier side. This leads to business benefits in lower cost, reliable supplier, besides non-interruption at the supplier end due to EHS incidents. Yes, these process/ mind set change are long drawn process and can take anywhere between 4-6 years of active engagement of cross funcational team with a great leadership Vigil.

Karthik

31st July 2023.

Images are from www at open source.