Fatality investigations in a manufacturing facility are among the most critical and sensitive investigations an organization can undertake. The primary goal is to determine the root causes of the incident, prevent similar incidents in the future, and provide closure for the affected employees and their families. Here are the key steps in fatality investigations in a manufacturing facility, elaborated:

-

Immediate Response and Safety:

- Priority: Ensure the safety and well-being of all employees in the immediate aftermath of the incident. Provide medical care for the injured and secure the scene to prevent further harm.

- Documentation: Document the incident scene with photographs, sketches, and measurements. Preserve any evidence, including equipment involved.

-

Notification and Compliance:

- Regulatory Authorities: Notify relevant regulatory authorities, such as the Occupational Safety and Health Administration (OSHA) in the United States or the equivalent authority in your country.

- Compliance: Cooperate fully with regulatory authorities, including permitting access for inspections and investigations.

-

Internal Investigation Team:

- Composition: Assemble an internal investigation team with diverse expertise, including safety professionals, engineers, and legal counsel. Appoint a lead investigator to oversee the process.

- Independence: Ensure the investigation team is independent of the department or area where the incident occurred to avoid conflicts of interest.

-

Gather and Analyze Information:

- Witness Interviews: Interview all witnesses, survivors, and employees with knowledge of the incident. Document their statements and gather information about the sequence of events.

- Documentation Review: Examine relevant records, including maintenance logs, training records, procedures, and previous incident reports.

- Physical Evidence: Examine physical evidence, such as equipment, machinery, and tools involved in the incident. Evaluate the conditions of these items for potential malfunctions or defects.

-

Root Cause Analysis:

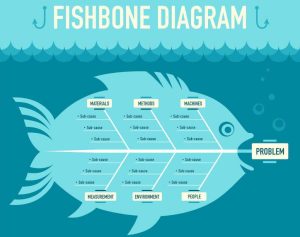

- Cause Identification: Conduct a thorough root cause analysis to identify all contributing factors. Use methods like the “5 Whys” or “Fishbone” diagrams to explore systemic and underlying causes.

- Human Factors: Consider human factors, such as worker behavior, training, and communication, alongside equipment-related factors.

-

Safety and Compliance Assessment:

- Compliance with Regulations: Evaluate whether the facility was in compliance with all relevant safety regulations and industry standards.

- Safety Protocols: Review and assess safety protocols, including emergency response procedures, to determine if they were effective in preventing or mitigating the incident.

-

Recommendations and Corrective Actions:

- Report: Prepare a detailed report outlining the root causes and recommendations for corrective actions. Ensure the report is clear, accurate, and evidence-based.

- Preventive Measures: Identify preventive measures to eliminate or mitigate the root causes. Develop an action plan with specific timelines and responsibilities for implementation.

- Legal Compliance: Ensure that the proposed corrective actions also align with any legal or regulatory requirements.

-

Communication and Reporting:

- Communication with Affected Parties: Communicate openly and compassionately with the affected employees and their families. Provide support and information to help them through the process.

- Reporting to Management and Stakeholders: Present the investigation findings and recommendations to senior management and stakeholders. Discuss the proposed corrective actions and their implications for the organization.

-

Documentation and Follow-Up:

- Records: Maintain detailed records of the investigation process, findings, corrective actions, and their implementation.

- Follow-Up: Regularly review the status of corrective actions and follow up on their progress. Adjust the action plan as needed.

-

Continuous Improvement:

- Learning from Incidents: Encourage a culture of continuous improvement. Ensure that lessons learned from the fatality investigation are applied throughout the organization to prevent future incidents.

-

Legal Considerations:

- Consult with legal counsel to address any potential legal issues, including liability, insurance claims, and regulatory compliance.

-

Closure and Support:

- Provide support to the affected employees and their families throughout the process. Ensure they have access to counseling and resources for coping with the emotional impact of the incident.

-

Regulatory Reporting:

- Comply with any required regulatory reporting, which may include the submission of investigation reports to authorities.

Fatality investigations are complex and emotionally challenging, and it’s crucial to conduct them thoroughly, transparently, and with utmost care. The insights gained from these investigations are invaluable for preventing future incidents and promoting a safer work environment.

++ Root Cause Analysis -Key Steps 7 aspects.

++ Root Cause Analysis -Key Steps 7 aspects.

When conducting a root cause analysis (RCA) for an incident or problem, it’s essential to consider the seven aspects of basic causes. These aspects help identify the fundamental reasons behind an issue and guide the development of effective corrective actions. Here’s an elaboration on each of these aspects:

-

Training:

- What it involves: This aspect examines whether individuals involved in the incident had the necessary training and knowledge to perform their tasks safely and effectively.

- Why it’s important: Insufficient training can lead to errors, accidents, and quality issues. Identifying gaps in training helps ensure that employees are adequately prepared for their roles.

- Key questions: Were employees properly trained for their specific tasks? Did they receive updated training when procedures or equipment changed?

-

Procedures:

- What it involves: Procedures encompass the documented processes and guidelines that employees should follow when performing tasks. This aspect examines whether procedures were followed and if they are effective.

- Why it’s important: Deviations from established procedures can lead to errors and incidents. Evaluating procedures helps improve their clarity and relevance.

- Key questions: Were documented procedures in place? Were they accessible and understood? Were they followed as intended, or were shortcuts taken?

-

Quality Control/Checks/Implementation:

- What it involves: This aspect assesses the quality control measures, checks, and implementation of processes to ensure that products or services meet established standards.

- Why it’s important: Quality issues can result in defects, customer complaints, and safety concerns. Evaluating quality control processes helps prevent recurrence.

- Key questions: Were quality control measures in place and effective? Were checks performed at critical stages? Were deviations from standards addressed promptly?

-

Human Engineering:

- What it involves: Human engineering focuses on the design of systems, tools, and equipment to match human capabilities and limitations.

- Why it’s important: Poorly designed workspaces or equipment can contribute to errors, discomfort, and injuries. Assessing human engineering helps create safer and more efficient work environments.

- Key questions: Were workspaces ergonomically designed? Were tools and equipment user-friendly? Were human factors considered in system design?

-

Communications:

- What it involves: Effective communication within an organization is crucial. This aspect examines whether information flows smoothly, and whether there is clarity in messaging.

- Why it’s important: Miscommunication can lead to misunderstandings, mistakes, and safety hazards. Evaluating communication helps improve transparency and clarity.

- Key questions: Were messages and instructions clear and easily understood? Was there timely communication of critical information? Were feedback channels open and responsive?

-

Management Systems:

- What it involves: Management systems encompass policies, procedures, and practices that guide an organization’s operations. This aspect assesses the effectiveness of these systems in ensuring safety and quality.

- Why it’s important: Weak management systems can result in organizational dysfunction and poor decision-making. Evaluating management systems helps enhance overall performance.

- Key questions: Were management systems aligned with safety and quality objectives? Were they effectively implemented and monitored? Did they promote a culture of continuous improvement?

-

Work Directions:

- What it involves: Work directions refer to how tasks are assigned, supervised, and executed within an organization.

- Why it’s important: Ambiguous or inadequate work directions can lead to confusion and errors. Evaluating work directions helps ensure that tasks are carried out correctly.

- Key questions: Were work directions clear and aligned with organizational goals? Were supervisors and workers on the same page regarding expectations? Were roles and responsibilities defined?

In an RCA, examining these seven aspects of basic causes provides a comprehensive view of the factors contributing to an incident or problem. It enables organizations to identify systemic weaknesses and implement targeted improvements to prevent future occurrences.

++

Summary:-

A fatality investigation is a thorough and systematic examination of the circumstances surrounding a death. The purpose of a fatality investigation is to:

- Determine the cause and manner of death

- Identify any factors that contributed to the death

- Recommend measures to prevent similar deaths from happening in the future

Fatality investigations are conducted by a variety of agencies and organizations, including coroners, medical examiners, police departments, occupational safety and health agencies, and other regulatory bodies. The scope of a fatality investigation will vary depending on the circumstances of the death, but it may include the following activities:

- Scene investigation: Investigators will examine the scene of the death to collect evidence and identify any potential hazards.

- Interviews: Investigators will interview witnesses, family members, and other relevant individuals to gather information about the deceased and the circumstances of the death.

- Medical examination: A medical examiner or pathologist will perform an autopsy to determine the cause and manner of death.

- Toxicology testing: Toxicology tests may be performed to determine if the deceased was under the influence of drugs or alcohol at the time of death.

Once the investigation is complete, the investigator will prepare a report that summarizes the findings and makes recommendations to prevent similar deaths from happening in the future. The report may be shared with the deceased’s family, the employer, and other relevant stakeholders.

Fatality investigations are an important tool for preventing deaths and improving safety. By identifying the factors that contribute to fatalities, investigators can develop recommendations to reduce the risk of similar deaths occurring in the future.

Here are some examples of recommendations that may be made in a fatality investigation report:

- Implement new safety procedures or training programs

- Improve the design of equipment or machinery

- Increase enforcement of safety regulations

- Conduct public awareness campaigns about safety hazards

By implementing the recommendations of fatality investigations, organizations and individuals can help to create a safer environment for everyone.