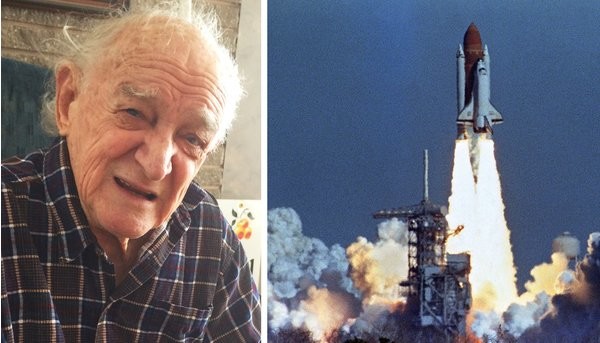

My marriage took place on the day Bush Sr. gave the command to Gen Norman Schwarzkopf to bomb Baghdad. (1/18) Coincidentally, my career at Ankleshwar, began on the day the Challenger exploded just 70 seconds into launch. People watched the horror live on television. (Internet was yet to penetrate, it came 10 years later!).

As I reflect today, on the 38th Anniversary of the Challenger Explosion (28th Jan), it’s a reminder that even the best-laid plans can go astray. Let’s delve into the lessons learned from that tragic event.”

Here’s a brief background on the Challenger and the Space Shuttle program for introduction:

The Challenger Space Shuttle, designated OV-099, was a part of NASA’s Space Shuttle program. It tragically disintegrated 73 seconds after liftoff on January 28, 1986, during mission STS-51-L. The seven-member crew, including school teacher Christa McAuliffe, lost their lives.

The Space Shuttle program, initiated in the early 1980s, aimed to provide reusable access to space. Challenger was the second orbiter to join the fleet and had completed nine successful missions before the fateful incident. The disaster marked a significant setback for NASA and prompted a reevaluation of safety procedures in space exploration.

There was pressure to proceed with the Challenger launch on January 28, 1986, partly due to the desire to have the launch coincide with President Ronald Reagan’s State of the Union address. The schedule constraints added to the urgency and may have contributed to the decision-making breakdowns.

Here’s a brief list of learning lessons from the Challenger disaster:

- Communication Breakdown: Highlight the importance of clear communication between engineering and management.

- Organizational Culture: Discuss the impact of organizational culture on decision-making and safety.

- Risk Assessment: Emphasize the need for thorough risk assessments and addressing concerns from all team members.

- Leadership Responsibility: Stress the role of leadership in ensuring the safety and well-being of team members.

- Ethical Decision-Making: Explore the ethical dimensions of the decisions made leading up to the disaster.

List of communication breakdowns in the Challenger disaster:

- Failure to Transmit Concerns: Engineers expressed concerns about O-rings but were not able to effectively communicate the risks to higher management.

- Decision-Making Process: Lack of open communication in the decision-making process, with key information not reaching the decision-makers.

- Pressure to Launch: Pressure from management to proceed with the launch despite technical concerns, leading to a breakdown in communication about the risks involved.

These breakdowns underscore the importance of transparent communication in preventing such incidents.

Organizational culture factors that played a part in the Challenger disaster:

- Suppressing Concerns: A culture where lower-level employees felt hesitant to voice concerns to higher-ups, leading to the suppression of critical information about the O-rings.

- Emphasis on Schedule: A culture that prioritized meeting tight schedules and deadlines over thorough risk assessment and safety protocols.

- Hierarchy Impact: Hierarchical structures that hindered the flow of information and discouraged open communication about potential issues.

These cultural factors highlight the need for fostering a culture that encourages open communication and prioritizes safety over expediency.

Poor risk assessment in the Challenger disaster was evident in several aspects:

- O-Ring Vulnerability: Inadequate assessment of the vulnerability of the solid rocket booster O-rings at low temperatures. The risks associated with these conditions were not thoroughly analyzed.

- Lack of Data Sharing: Insufficient sharing of crucial information between engineers and management regarding previous incidents of O-ring erosion, leading to an underestimation of the potential risks.

- Overconfidence: Overconfidence in the reliability of the shuttle system, leading to a complacent attitude towards potential risks and a failure to anticipate the consequences of a flawed launch.

These shortcomings underscore the critical importance of robust risk assessment processes in ensuring the safety of complex systems like space shuttles.

The Challenger disaster wasn’t solely caused by a single individual’s fault, but rather a series of interconnected leadership failures at different levels within NASA and its contractor Morton Thiokol. Here are some key points:

Prioritizing schedule over safety:

- NASA management pressure: Launch schedules held immense importance, overshadowing potential safety concerns. Pressure to maintain launch deadlines influenced decisions despite engineers’ warnings.

- External political pressure: Political factors and public expectations for maintaining the space program’s momentum contributed to overlooking risks.

Ignoring and downplaying concerns:

- Engineers’ voices silenced: Engineers expressing concerns about the O-rings faced pressure and lacked clear channels to escalate their worries. Their warnings were downplayed or dismissed.

- Data ignored: Crucial data from previous launches demonstrating issues with O-rings at cold temperatures was excluded from the final risk assessment.

- Underestimating risks: The potential consequences of a failure were downplayed, focusing on the likelihood of success rather than worst-case scenarios.

Communication failures:

- Information silos: Engineers raising concerns encountered communication barriers, hindering effective communication with decision-makers.

- Lack of transparency: Information flow within NASA was limited, preventing a complete understanding of the risks and hindering informed decision-making.

Organizational culture:

- Can-do attitude: A pervasive “can-do” culture prioritizing success overcaution discouraged raising safety concerns and fostered a reluctance to admit potential problems.

- Groupthink: Decisions were made through consensus, potentially leading to overlooking dissenting voices and overlooking potential red flags.

Contractor pressure:

- Morton Thiokol’s initial recommendation: Despite engineers’ concerns, management initially recommended against launch due to the cold temperatures. However, under pressure from NASA, they reversed their stance, prioritizing the contract over safety concerns.

Ethical decision-making played a significant role in the Challenger disaster:

- Ignoring Engineer Warnings: The decision-makers chose to proceed with the launch despite knowing about concerns raised by engineers regarding the O-rings, reflecting a disregard for ethical responsibility to prioritize safety over other considerations.

- Pressure to Meet Schedule: The push to align the launch with the State of the Union address and adhere to the schedule added ethical dilemmas, as decision-makers compromised on safety for political and organizational goals.

- Incomplete Information to Decision-Makers: Ethical decision-making requires providing decision-makers with complete and accurate information. In this case, incomplete information about O-ring vulnerabilities hindered a comprehensive ethical evaluation.

Examining these ethical aspects highlights the importance of prioritizing safety and ensuring transparent communication in decision-making processes.

As we wrap up this reflection on the Challenger disaster’s 38th anniversary, it serves as a poignant reminder that the pursuit of knowledge and progress often comes with unforeseen challenges. Let’s carry forward the lessons learned – the importance of transparent communication, ethical decision-making, and rigorous risk assessment. In our endeavors, may we strive not only for success but, above all, for a future where safety and humanity prevail. Stay safe, stay informed, and continue the journey of learning.

Until the next reflection,

Karthik.

28th Jan 2024. Bangalore.

PS: 28th Jan 1991, A girl came 1000 miles with a man whom she knew for about 100 hrs to began her married life alone to an alien land in which she had no clue of the language, culture, people and food! That is Lalitha for you! Resillience personified!