#151

“Unraveling the Tragedy: The Crucial Role of Near Miss Reporting in Industrial Safety”

Introduction: Last night, a chilling incident unfolded in the Baddi Perfume factory (NR Aromas) in Himachal Pradesh, revealing a devastating fire that claimed lives and left many missing. Through a Telegram channel, I came across videos showcasing a spectacular fireball show, emphasizing the gravity of the situation. As the confirmed death toll reaches four, and the fire, now almost under control after 20 hours, paints a gruesome picture of the incident, it’s imperative to delve into why such tragedies occur.

In this blog post, I aim to shed light on the critical importance of near-miss reporting. Incidents like the one in Baddi don’t happen suddenly; (I am not speculating anything, we will never know the true cause as are cases in India) they often leave warning signs. These near misses, such as minor fires, spills, or static charge dissipation incidents, if addressed promptly, could prevent major catastrophes. Additionally, the implementation of fire protection measures, including sprinklers, hydrants, rescue plans, emergency exits, and regular mock drills, could significantly mitigate the impact of such incidents. The challenge lies in overcoming the industry’s tendency to develop wisdom only post-events, a practice that proves too late for preventing tragedies. Let’s explore how proactive near-miss reporting can be a powerful tool in averting such calamities.

Definition of Near Miss:

It’s often easy to rationalize accidents, attributing them to special circumstances that seem unlikely to recur, or downplaying the severity with statements like “it could have been worse.” This tendency to self-justify is known as self-justification.

Solan DC Man Mohan Sharma said the fire has been controlled but it is too risky to enter the complex. (20 Hrs on).

However, when we delve into the definition and classification of a near miss, a more thoughtful approach is required. A near miss encompasses any hazardous situation that, fortunately, did not result in an actual accident. Identifying near misses demands a keen awareness of dangerous circumstances and actions before they escalate into a full-blown incident. It necessitates sharp observational skills, sound judgement, and critical thinking.

Examples of Near Misses:

- Unsafe Actions:

- Parking a vehicle too close to moving traffic

- Working outdoors in wet weather

- Engaging in live-line work without the required qualification or protective clothing

- Using improper tooling for a specific activity

- Unsafe Conditions:

- Toppling a heavy object that narrowly misses a person on the ground below

- Working with inadequate shielding on equipment with moving parts

- Operating on tethered conductors placed too closely to sharp tools in active use

- Non-conformance:

- Process or procedural failures that could lead to potential hazards

- Dangerous Incidents:

- Instances where hidden hazards are identified and addressed before turning into accidents.

- Hidden Hazards / Others.

The key lies in recognizing these near misses, investigating their root causes, and implementing corrective actions promptly. This proactive approach is essential for preventing potential accidents and fostering a safer working environment.

Why Reporting a Near Miss is Essential:

- Preventive Measures:

- Early identification of near misses allows for the implementation of preventive measures to address root causes, reducing the likelihood of similar incidents in the future.

- Continuous Improvement:

- Reporting near misses fosters a culture of continuous improvement. Understanding the factors contributing to near misses enables organizations to refine safety protocols and enhance overall safety performance.

- Risk Mitigation:

- Addressing near misses helps mitigate potential risks before they escalate into accidents, protecting both personnel and property.

- Employee Awareness:

- Encourages heightened awareness among employees, fostering a proactive mindset toward safety and creating a shared responsibility for a safe working environment.

- Legal Compliance:

- Reporting near misses ensures compliance with legal and regulatory requirements, demonstrating a commitment to maintaining a safe workplace.

Benefits of Reporting Near Misses:

- Prevent Future Accidents:

- Early reporting allows for corrective actions to prevent similar accidents, contributing to a safer work environment.

- Cost Savings:

- Proactively addressing near misses reduces the financial impact associated with potential accidents, such as medical expenses, property damage, and legal liabilities.

- Enhanced Safety Culture:

- Fosters a culture where safety is a priority, encouraging open communication and collaboration among team members.

- Improved Morale:

- Employees feel valued and engaged when their input on near misses is acknowledged, contributing to improved morale and job satisfaction.

- Data for Analysis:

- Provides valuable data for trend analysis, helping organizations identify recurring patterns and areas for improvement in safety protocols.

What Prevents Reporting a Near Miss:

- Fear of Punishment:

- Employees may fear reprisals or punishment for reporting near misses, leading to underreporting.

- Lack of Awareness:

- Employees might not be fully aware of what constitutes a near miss or the potential consequences, resulting in a failure to report.

- Time Constraints:

- Busy work schedules and tight deadlines may discourage employees from taking the time to report near misses.

- Perceived Unimportance:

- Some individuals may perceive near misses as insignificant or not worth reporting, underestimating their potential impact.

- Lack of Reporting Systems:

- Inadequate reporting mechanisms or a lack of clear procedures may hinder the reporting of near misses.

- ++++++

Encouraging a culture of openness, emphasizing the positive outcomes of reporting, and addressing barriers can help overcome these challenges and promote effective near-miss reporting.

Prerequisites for a Near Miss Reporting Culture:

- Leadership Commitment:

- Strong commitment from top leadership to prioritize safety and communicate its importance throughout the organization.

- Open Communication Channels:

- Establish transparent and easily accessible communication channels for employees to report near misses without fear of reprisal.

- Training and Awareness Programs:

- Conduct regular training sessions to educate employees on what constitutes a near miss, the importance of reporting, and how it contributes to overall safety.

- Anonymous Reporting Option:

- Provide an option for anonymous reporting to encourage employees who may be hesitant to come forward due to fear or other concerns.

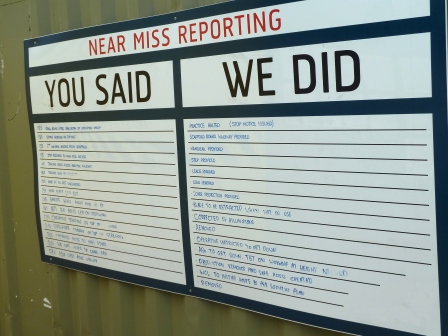

- Feedback Mechanism:

- Implement a feedback mechanism to acknowledge and communicate the actions taken in response to reported near misses, reinforcing the value of reporting.

- Just Culture Approach:

- Foster a “just culture” where reporting is seen as a learning opportunity rather than a blame-seeking exercise, promoting open dialogue on safety improvement.

- Integration with Existing Processes:

- Integrate near miss reporting seamlessly into existing safety processes to make it a natural part of the organization’s safety culture.

- Incentives and Recognition:

- Establish a system of incentives or recognition to motivate employees to actively participate in near miss reporting.

- Continuous Improvement Loop:

- Implement a continuous improvement loop by analyzing reported near misses, identifying root causes, and implementing corrective actions to prevent recurrence.

- Clear Reporting Guidelines:

- Provide clear and concise guidelines on how to report near misses, including what information is required and how the reporting process works.

- Regular Audits and Assessments:

- Conduct regular audits and assessments to evaluate the effectiveness of the near miss reporting culture and make necessary adjustments.

- Employee Involvement:

- Involve employees in the development and improvement of the near miss reporting process, creating a sense of ownership and engagement.

By establishing these prerequisites, organizations can create a robust near miss reporting culture that not only identifies potential hazards but also promotes a proactive approach to safety and continuous improvement.

+++++

Roles of Personnel in Nearmiss management:-

Senior Leadership:

- Champion Safety Culture: Set the tone for a safety-first culture by visibly prioritizing and advocating for safety at all levels of the organization.

- Allocate Resources: Ensure adequate resources are allocated for safety initiatives, including near miss reporting systems and investigations.

- Provide Support: Support and endorse safety policies, encouraging a proactive approach to near miss reporting.

Managers:

- Lead by Example: Demonstrate a commitment to safety through their actions, reinforcing the importance of reporting and investigating near misses.

- Facilitate Reporting: Create an environment that encourages open communication and reporting, emphasizing the value of near miss information.

- Implement Corrective Actions: Act promptly on reported near misses, implementing corrective actions to address root causes and prevent future incidents.

Employees:

- Report Promptly: Actively participate in near miss reporting, understanding the critical role they play in identifying potential hazards.

- Stay Informed: Stay informed about safety protocols and guidelines, contributing to a safer work environment through awareness and vigilance.

- Engage in Training: Participate in safety training sessions to enhance awareness and understanding of near misses and their reporting.

Contractors:

- Adhere to Safety Standards: Follow established safety standards and guidelines, reporting any near misses promptly to the relevant authorities.

- Communicate Hazards: Communicate potential hazards to the responsible parties, contributing to a safer work environment for all stakeholders.

Safety Professionals:

- Facilitate Reporting Systems: Implement effective near miss reporting systems and processes, ensuring they are accessible and well-understood.

- Conduct Investigations: Lead thorough investigations into reported near misses, identifying root causes and recommending corrective actions.

- Provide Training: Offer training sessions to enhance the awareness and understanding of near miss reporting among all stakeholders.

Safety Committee Members:

- Review Reported Near Misses: Regularly review and analyze reported near misses to identify trends and patterns.

- Recommend Improvements: Make recommendations for safety improvements based on the analysis of near misses, contributing to proactive safety management.

- Promote Safety Culture: Act as ambassadors for safety culture, encouraging and promoting near miss reporting within the organization.

By effectively engaging each stakeholder group in their respective roles, organizations can establish a comprehensive and proactive approach to near miss reporting and investigation, fostering a safer work environment.

++++

Nearmiss investigation takes time and is a pain? Myth or reality?

Near miss investigations may take time, but considering them a pain is more of a myth. The investment in time for a thorough investigation is an essential component of proactive safety management. While it might seem burdensome initially, the benefits far outweigh the perceived challenges.

Easy, Quick Methods to Investigate Near Miss Incidents:

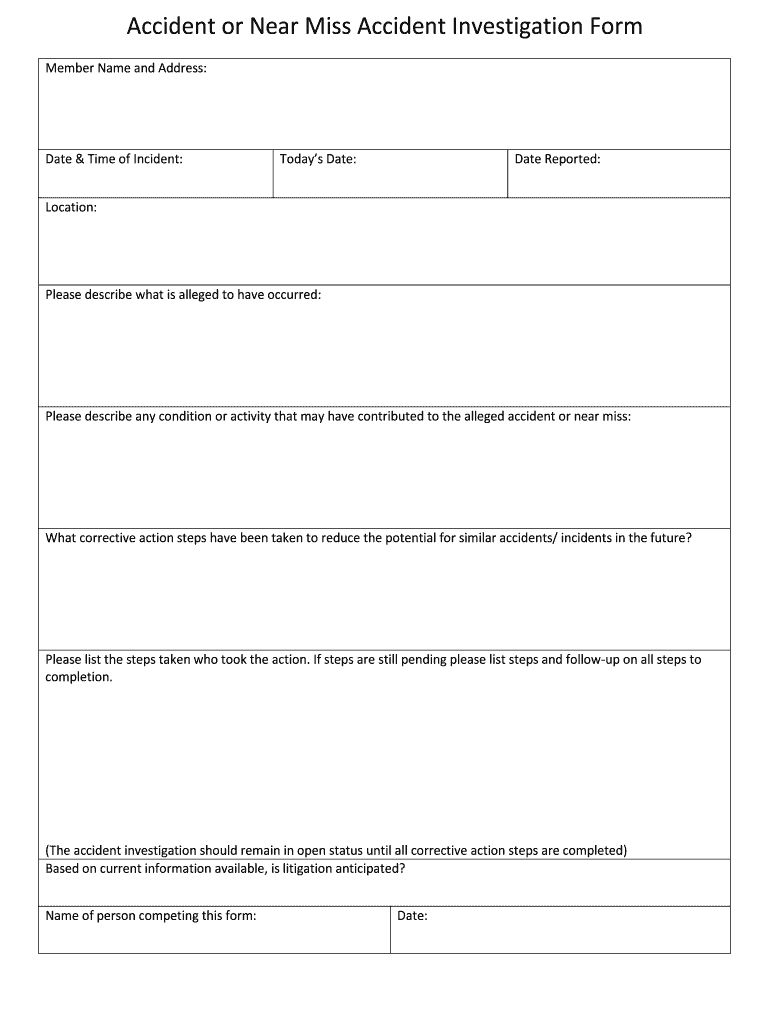

- Initial Documentation:

- Quickly document the basic details of the near miss, including date, time, location, and a brief description of the incident.

- Witness Statements:

- Interview witnesses promptly to gather firsthand accounts and perspectives on the near miss.

- Photographic Evidence:

- Take photographs of the incident scene to capture visual evidence, aiding in the investigation and analysis.

- Checklists and Templates:

- Utilize pre-prepared checklists or templates to guide the investigation process, ensuring key aspects are covered efficiently.

- Root Cause Analysis:

- Conduct a simplified root cause analysis, focusing on identifying the immediate and underlying factors contributing to the near miss. (5 Why with 6M—> Man, Method, Material, Measurement, Machine, Mileu(Environment)

- Employee Involvement:

- Involve employees who witnessed or were directly affected by the near miss in the investigation process to gather diverse perspectives.

- Use Technology:

- Leverage technology for quick reporting and analysis, such as mobile apps or online platforms that streamline the investigation process.

Quick Implementation of Recommendations:

- Prioritize Corrective Actions:

- Quickly prioritize corrective actions based on the identified root causes, focusing on immediate and effective solutions.

- Interim Measures:

- Implement interim measures to address immediate risks while long-term solutions are being developed and implemented.

- Communication:

- Communicate the recommended actions promptly to all relevant stakeholders, ensuring a clear understanding of the required changes.

- Training and Awareness:

- Initiate brief training sessions or awareness programs to educate employees on the lessons learned from the near miss and the implemented recommendations.

- Monitor Progress:

- Establish a system to monitor the progress of implemented recommendations, ensuring they are effective in preventing recurrence.

- Continuous Improvement Loop:

- Use the insights gained from the near miss investigation to continually improve safety protocols and procedures.

By combining these quick and practical methods for near miss investigation with prompt implementation of recommendations, organizations can efficiently enhance their safety management systems and prevent potential accidents.

Conclusion:

Reflecting on the tragic incident at the Baddi Perfume factory, where a devastating fire claimed lives and left a lasting impact, it becomes evident that proactive safety measures could have played a pivotal role in preventing such a catastrophic event. The fire, with its spectacular and horrifying visuals, underscores the critical importance of implementing robust safety protocols, especially when considering the potential hazards in manufacturing units.

A proactive approach to near miss reporting and investigation could have unveiled warning signs, such as minor fires, spills, or unsafe practices, that might have served as precursors to the major incident. These crucial indicators, if recognized and addressed promptly, could have prevented the escalation of events leading to the loss of lives.

Yet, it’s a harsh reality that companies often display a short memory when it comes to safety. The tendency to become wiser only after an incident occurs poses a serious challenge. It underscores the need for a cultural shift towards embracing a proactive, continuous improvement mindset regarding safety. Companies must break free from the cycle of forgetfulness, invest in comprehensive safety measures, and uphold the lessons learned from incidents like the Baddi factory fire.

In conclusion, the Baddi incident serves as a somber reminder of the consequences of neglecting safety and the urgent need for companies to adopt proactive measures, ensuring the safety of their workforce and the surrounding communities. The memory of such tragedies should not fade away but serve as a constant impetus for organizations to prioritize safety, learn from near misses, and prevent the recurrence of devastating incidents.

Acknowledgement:- ISSA Guide on Nearmiss reporting,Cologne, Germany. (Guidance on How to manage near misses).