#173

Introduction:

Safety in the workplace is evolving into a multifaceted and intricate domain, with far-reaching implications across various facets of business operations. Gone are the days when safety was solely the concern of designated safety professionals. Today, its domain outreach intersects not only within the realms of Environment, Health, and Safety (EHS) but also with crucial aspects of operations, quality, productivity, inventory, delivery (logistics), and cost (finance). This expanding scope poses a significant challenge, as it’s no longer feasible for just safety professionals to manage the entire game effectively.

In this dynamic landscape, safety has transcended its traditional boundaries to become a collective responsibility shared by all stakeholders within an organization. EHS personnel now operate as internal consultants, leveraging their expertise to navigate the complex regulatory requirements governing safety practices. However, their role extends beyond mere compliance, encompassing proactive risk management and fostering a culture of safety excellence.

Crucially, line managers must assume an active role in safety initiatives, recognizing that safety is not just a box to be checked but an integral component of operational success. Their active participation is essential for embedding safety into the fabric of everyday operations and instilling a safety-first mindset throughout the organization.

As we delve deeper into the intricacies of safety implementation in manufacturing environments, it’s imperative to recognize the collective responsibility that underpins modern safety practices. By embracing this ethos and fostering collaboration across departments, organizations can navigate the complexities of safety management with agility and resilience.

Shared Responsibility:-

In today’s increasingly complex safety landscape, the notion of safety being solely the responsibility of designated safety personnel is outdated. Instead, it’s crucial to recognize that safety is a collective responsibility that extends to every individual within an organization, irrespective of their technical role. This shift in mindset is imperative as safety operations become more intricate and intersect with various operating domains. As safety operations evolve, they inevitably overlap with other critical functions within an organization, such as operations, quality, productivity, inventory management, logistics, and finance. The complexity of modern safety practices means that no single function can possess all the requisite knowledge and expertise to execute safety measures effectively. Instead, a collaborative approach is essential, with each department contributing its unique insights and capabilities to the overall safety effort.

In this coordinated framework, every individual becomes a stakeholder in the safety journey, with a shared goal of ensuring a safe workplace for all. Whether they are on the shop floor, in the boardroom, or managing operations, each person plays a crucial part in identifying hazards, implementing safety protocols, and promoting a culture of safety excellence. By fostering a culture of shared responsibility, organizations can leverage the collective wisdom and expertise of their workforce to address safety challenges comprehensively.

Basic Safety Knowledge:

Non-safety personnel must grasp fundamental safety systems, processes, and programs to contribute effectively to workplace safety. This includes understanding emergency procedures, such as evacuation routes and assembly points, to ensure swift and organized responses to potential crises. Additionally, they should be proficient in hazard identification techniques to recognize and report potential dangers in their work environment. Moreover, a solid grasp of risk assessment methodologies enables employees to evaluate the likelihood and severity of hazards, facilitating informed decision-making to mitigate risks proactively. They can refer to ISO 45001 / ISO 14001, for gaining valuble information on these topics.

Leadership and Culture:

Leadership plays a pivotal role in shaping the safety culture of an organization. Non-safety personnel should recognize that their attitudes and behaviors have a significant impact on overall safety culture. Leaders must lead by example, demonstrating a commitment to safety through their actions and decisions. By fostering open communication channels, encouraging employee participation, and providing resources for safety initiatives, leaders can create an environment where safety is prioritized at every level of the organization. Moreover, leaders should actively promote a culture of continuous improvement, where feedback is valued, and safety processes are regularly reviewed and refined.

Technical Understanding:

Non-safety personnel must understand how their technical knowledge intersects with safety to effectively identify and mitigate risks in their work processes. Key traits for active engagement in safety include attention to detail, problem-solving skills, and a proactive mindset. By recognizing potential hazards inherent in their work processes, employees can take preemptive measures to eliminate or control risks. Moreover, they should be familiar with basic safety regulations and standards (Critical to Life, Health) relevant to their industry to ensure compliance and uphold safety best practices. Focus areas for success include regular safety training and education, participation in safety committees or teams, and proactive hazard reporting systems to address safety concerns promptly.

Training and Communication:

Ongoing training and clear communication channels are essential to ensure that all employees, regardless of their role, are equipped to contribute effectively to safety initiatives. Regular safety training sessions provide employees with the knowledge and skills necessary to identify hazards, implement safety protocols, and respond appropriately to emergencies. Moreover, clear communication channels facilitate the exchange of information regarding safety procedures, updates, and best practices, ensuring that everyone remains informed and engaged in safety efforts.

Continuous Improvement:

Encouraging a mindset of continuous improvement in safety practices is crucial for enhancing workplace safety. Non-safety personnel should be empowered to provide feedback and suggest improvements to existing safety systems based on their firsthand experiences and observations. By fostering a culture where feedback is valued and acted upon, organizations can identify areas for enhancement and implement proactive measures to mitigate risks and prevent incidents.

Accountability:

Accountability is paramount at all levels of an organization when it comes to safety. Non-safety personnel should understand that they are accountable for their actions and adherence to safety protocols. By holding individuals accountable for their safety responsibilities, organizations create a culture of accountability where everyone takes ownership of safety outcomes and strives to uphold safety standards.

Integration with Operations:

Safety should be seamlessly integrated into daily operations, rather than treated as an add-on or afterthought. Non-safety personnel should understand that safety is an integral part of their work processes and operations. By embedding safety considerations into every aspect of their work, (Design, Procedure Reviews, Implementation) employees can identify potential hazards, implement preventive measures, and prioritize safety alongside productivity and efficiency. Integration with operations ensures that safety becomes ingrained in the organizational culture and is prioritized in decision-making processes at all levels.

Real-Life Examples:

Neglecting safety can have severe consequences, both in terms of human lives and organizational reputation. One notable example is the bp, Deepwater Horizon oil spill in 2010. The catastrophic explosion resulted in the loss of 11 lives and caused extensive environmental damage in the Gulf of Mexico. An investigation revealed that a series of safety failures, including inadequate risk assessments, poor communication, and a lack of proper equipment maintenance, Short cuts in operations/ lack of proper technical knowledge of sub contractors contributed to the disaster. The incident not only had devastating environmental and economic consequences but also tarnished the reputation of the companies involved.

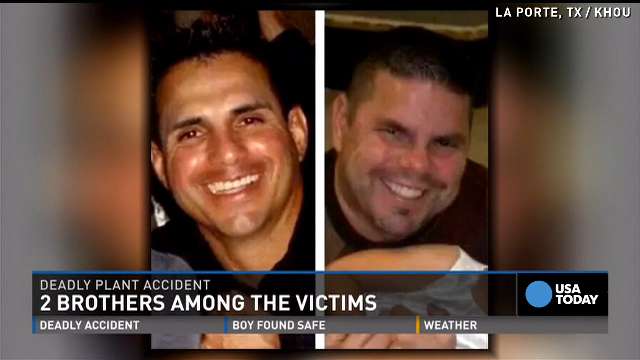

Another example that underscores the importance of safety is the tragic incident at a DuPont chemical plant in La Porte, Texas, in 2014. This incident resulted in the deaths of four workers due to exposure to methyl mercaptan, a highly toxic chemical used in pesticide production. An investigation by the U.S. Chemical Safety Board (CSB) revealed a series of safety lapses and deficiencies at the plant, including inadequate training, insufficient hazard assessments, and deficiencies in emergency response procedures. The DuPont incident serves as a stark reminder of the potential consequences of neglecting safety protocols and underscores the importance of robust safety management systems in high-risk industries. It also highlights the need for continuous vigilance and improvement in safety practices to prevent such tragedies from recurring.

Encouraging Ownership:

Empowering non-safety personnel to take ownership of safety initiatives is essential for creating a culture of safety excellence. By actively participating in safety meetings, employees gain valuable insights into safety protocols and contribute their perspectives to enhance safety practices. Additionally, encouraging employees to report hazards enables organizations to identify and address potential risks before they escalate into incidents. Moreover, championing safety best practices within teams fosters a sense of collective responsibility and reinforces the importance of safety in everyday operations. By embracing ownership of safety initiatives, non-safety personnel become proactive stewards of workplace safety, driving continuous improvement and fostering a culture where safety is everyone’s priority.

Conclusion:

In today’s dynamic and complex workplace environments, safety is not just the responsibility of designated safety personnel but a TEAM endeavor that requires the active participation of every individual. As safety operations intersect with various operating domains, it becomes increasingly evident that no single function can bear the entire burden of safety management. Instead, organizations must empower non-safety personnel to take ownership of safety initiatives, providing them with the knowledge, tools, and support needed to contribute effectively to workplace safety. By fostering a culture of shared responsibility, continuous improvement, and accountability, organizations can create safer, healthier, and more productive work environments for all. Together, let us embrace the ethos of ownership and champion safety as a fundamental value that guides our actions and decisions each day.

Good Luck and God Speed.

Karthik

23/4/24 1pm.