#179

Today, I’m excited to dive into a topic that’s both eye-opening and crucial for anyone working in high-risk environments: STKY – Stuff That Kills You. This term, coined by Tod Conklin in a recent podcast I had the pleasure of listening to, encapsulates the very essence of the hazards we face in critical operations. It’s a stark reminder that in our line of work, being aware of potential dangers isn’t just important – it’s a matter of life and death.

In this blog post, inspired by Tod Conklin’s insights, we’ll explore how we can keep ourselves alive and thriving while tackling the challenges of critical operations. From asking the right questions before starting work to fostering a culture of safety that empowers every individual on the team, we’ll uncover practical strategies for minimizing risks and maximizing safety.

In this blog post, inspired by Tod Conklin’s insights, we’ll explore how we can keep ourselves alive and thriving while tackling the challenges of critical operations. From asking the right questions before starting work to fostering a culture of safety that empowers every individual on the team, we’ll uncover practical strategies for minimizing risks and maximizing safety.

Overview:-

When it comes to critical operations, whether it’s working with heavy machinery, handling hazardous materials, or operating in high-risk environments, there’s no room for error. Here are some key tips to help you stay alive and well while on the job:

-

Know Your Risks: The first step in staying safe is understanding the risks associated with your job. Take the time to familiarize yourself with the potential hazards present in your work environment and how to mitigate them. (Familiarise with the Hazard Prompt List and Risks there on in your operating area). If not sure do not start the work.

-

Follow Safety Procedures: Safety procedures exist for a reason – to keep you safe. Make sure you follow them to the letter, whether it’s wearing personal protective equipment (PPE), using safety devices, or following established protocols.

-

Stay Alert and Focused: In critical operations, distractions can be deadly. Stay focused on the task at hand and remain vigilant for any signs of danger. Remember, it only takes a split second for an accident to occur.

-

Communicate Effectively: Communication is key, especially in high-risk situations. Make sure you communicate clearly with your colleagues and supervisors about any safety concerns or hazards you encounter.

-

Take Breaks When Needed: Fatigue can impair your judgment and reaction time, increasing the risk of accidents. Take regular breaks to rest and recharge, especially during long or demanding work shifts.

-

Report Near Misses: Near misses are valuable learning opportunities. If you experience or witness a near miss, report it immediately so that corrective action can be taken to prevent a future incident. Near miss reporting prevent future accidents, as near miss was luck factor this time. It may not be the next time.

-

Continuous Training and Education: Safety is an ongoing process, not a one-time event. Keep yourself updated on the latest safety practices and undergo regular training to refresh your skills and knowledge.

-

Don’t Take Shortcuts: When it comes to safety, there are no shortcuts. Cutting corners or bypassing safety procedures can have dire consequences. Always take the safest route, even if it means taking a little extra time.

-

Lead by Example: As a leader or supervisor, (If you are one) set a positive example for your team by prioritizing safety in everything you do. Your actions speak louder than words, so make sure they reflect a commitment to safety excellence.

-

Stay Informed: Finally, stay informed about industry trends, regulatory changes, and emerging technologies that could impact safety in your field. Knowledge is power when it comes to staying safe on the job.

Remember, safety is everyone’s responsibility – from the newest recruit to the most seasoned veteran. By staying vigilant, following safety procedures, and looking out for each other, we can all do our part to keep ourselves and our colleagues safe from STKY – Stuff That Kills You.

Pre Job Checks- Critical to Life work (Eg. LOTO, Haz.Chem, Electrical work, CSE, Height, Live work, etc.)

Before starting critical work, it’s essential to ask a series of questions to ensure that safety is prioritized and potential risks are identified and mitigated. Here are some key questions to consider:

-

What are the Hazards?: Identify the potential hazards associated with the task or operation. This includes physical hazards such as moving machinery, chemical hazards, environmental hazards, and any other risks specific to the work environment.

-

What Are the Safety Procedures?: Determine what safety procedures need to be followed before, during, and after the task. This may include wearing personal protective equipment (PPE), using safety devices, following lockout/tagout procedures, and any other safety protocols. Are safety procedures written in a simple language? Easy to comprehend.

-

Is Everyone Trained?: Ensure that all personnel involved in the task are properly trained and qualified to perform their roles safely. This includes training on equipment operation, hazard recognition, emergency procedures, and any other relevant topics.

-

Are There Any Special Precautions?: Identify any special precautions that need to be taken due to the unique nature of the task or the presence of specific hazards. This may include conducting a hazard assessment, implementing additional safety measures, or providing specialized training.

-

What Are the Emergency Procedures?: Establish clear emergency procedures in case of an accident, injury, or other unexpected event. Ensure that all personnel are familiar with these procedures and know how to respond effectively in an emergency situation.

-

Is the Work Area Secured?: Ensure that the work area is properly secured and free from potential hazards or obstacles. This may involve implementing barricades, signage, or other safety measures to prevent unauthorized access or ensure the safety of bystanders.

-

Are There Any Permit Requirements?: Determine if any permits or authorizations are required before starting the work. This may include permits for hot work, confined space entry, excavation, or other high-risk activities.

-

Have Potential Conflicts Been Addressed?: Identify any potential conflicts or interactions with other work activities, equipment, or personnel that could pose a safety risk. Take steps to mitigate these risks and ensure that all parties involved are aware of the potential hazards.

-

Is the Equipment in Good Condition?: Verify that all equipment and tools to be used in the task are in good working condition and properly maintained. Inspect equipment for any defects or malfunctions that could compromise safety and address any issues before starting the work.

-

Have Risk Control Measures Been Implemented?: Implement appropriate risk control measures to minimize the likelihood and severity of potential hazards. This may include engineering controls, administrative controls, or personal protective equipment to mitigate risks.

By asking these questions and addressing any potential safety concerns before starting critical work, you can help ensure that the task is completed safely and effectively, minimizing the risk of accidents or injuries.

Interaction and exchange with your Supervisor:-

Maintaining close contact and ensuring clear communication between supervisors and workers is crucial for promoting a safe work environment. Asking the following questions before proceeding with work and discussing it with your supervisor once, helps to reinforce safety awareness and ensure that workers understand the potential risks and necessary precautions: (Courtesy Todd Conklin).

-

What will kill you?: This question prompts workers to identify and acknowledge the specific hazards associated with the task at hand. By understanding what can potentially cause harm or injury, workers can better appreciate the importance of adhering to safety procedures and taking appropriate precautions.

-

When it happens, what keeps you safe?: This question encourages workers to consider the safety measures and protocols in place to protect them from the identified hazards. It prompts them to think about the role of personal protective equipment (PPE), engineering controls, safety procedures, and other measures in mitigating risks and keeping them safe on the job.

-

Is it enough?: After discussing the hazards and safety measures, this question prompts workers to assess whether the existing safety measures are sufficient to mitigate the identified risks effectively. It encourages critical thinking and empowers workers to speak up if they believe additional precautions or adjustments are necessary to ensure their safety.

Once workers are fully aware of the potential risks, safety measures, and their role in staying safe, the work can proceed with greater confidence and accountability. Regular reinforcement of safety awareness through open communication, training, and supervision helps to instill a strong safety culture where everyone takes responsibility for their own safety and the safety of their colleagues.

By incorporating these questions into pre-work discussions and ensuring that workers are fully engaged and informed, supervisors can help create a safer work environment where the risk of accidents and injuries is minimized. Remember, safety is a team effort, and proactive communication and collaboration are key to preventing incidents and ensuring everyone goes home safely at the end of the day.

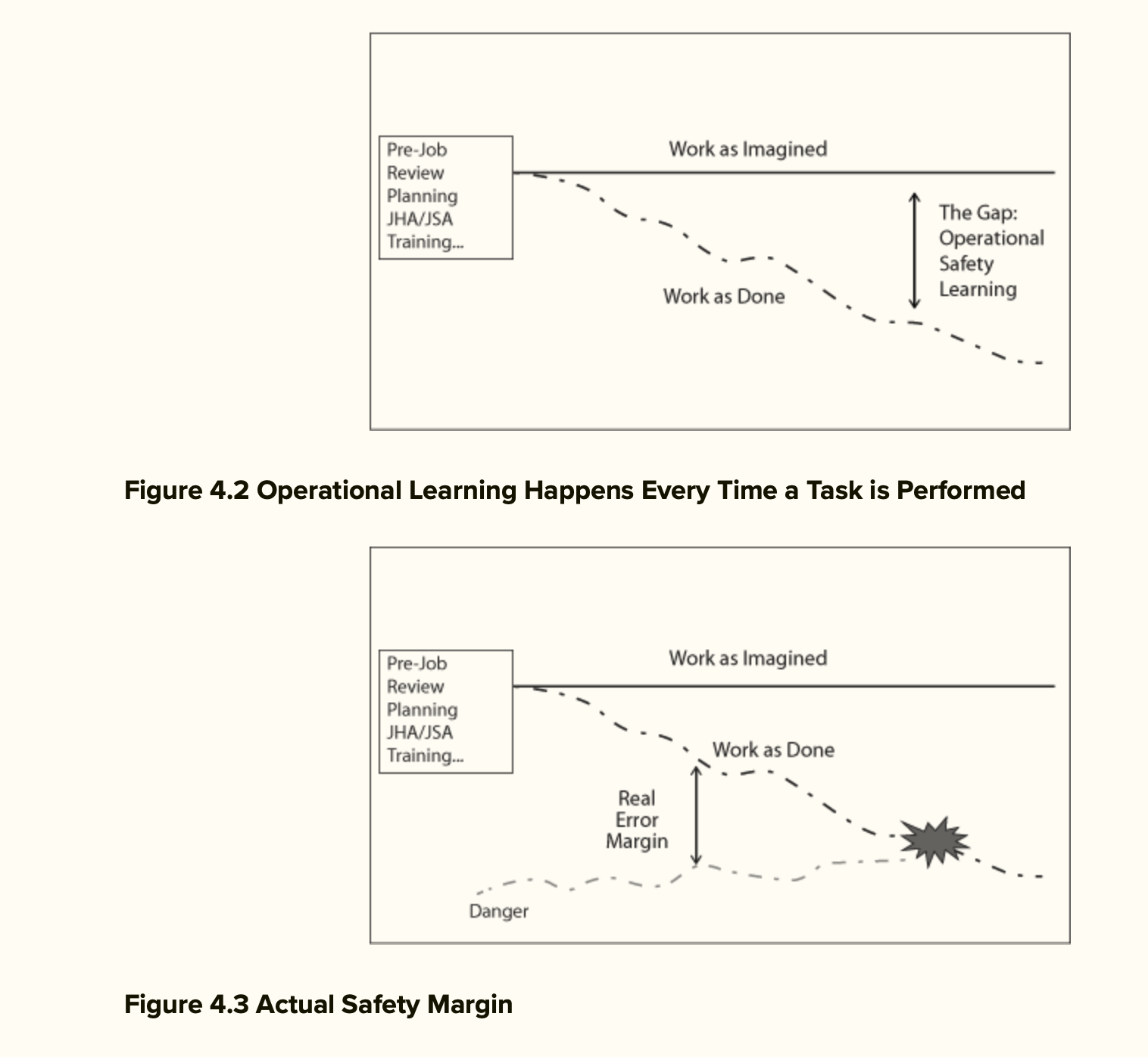

The Danger Curve that Lurks: (Courtesy Preaccident Investigations- Todd Conklin).

Post job questions to ask workers?

“Four Post-Job Questions: (Critical to life Jobs)

- What happened the way you thought it would happen?

- What surprised you?

- What hazards did we identify and what hazards did we miss?

- Where did you have to “make do,” improvise or adapt? (Deviations that were experienced/ taken to complete job).

By incorporating these questions into pre-work and post work discussions on critical jobs, and ensuring that workers are fully engaged and informed, supervisors can help create a safer work environment where the risk of accidents and injuries is minimized. Remember, safety is a team effort, and proactive communication and collaboration are key to preventing incidents and ensuring everyone goes home safely at the end of the day.

Karthik

9th May 2024, 1300 Hrs.