#183

Introduction:

In the fast-paced world of modern work, personal productivity stands as the cornerstone of professional success. It’s the fuel that drives efficiency, effectiveness, and ultimately, achievement. Yet, achieving and maintaining peak productivity isn’t just about ticking off tasks on a to-do list—it’s a multi-faceted endeavor that requires a holistic approach.

At its core, personal productivity is the art of managing one’s time, energy, and resources to accomplish tasks and goals effectively. It’s about striking the delicate balance between quantity and quality, between output and well-being. But beyond the conventional understanding of productivity lies a deeper, more comprehensive perspective—one that takes into account not only the tangible aspects of work but also the intangible aspects of human experience.

Enter the holistic approach to productivity—a paradigm that transcends traditional notions of efficiency and time management to encompass the entirety of the professional experience. This approach recognizes that true productivity isn’t achieved through sheer willpower or relentless hustle alone. Instead, it acknowledges the interconnectedness of various factors—physical, mental, emotional, and even spiritual—that influence our ability to perform at our best.

In embracing a holistic approach, we shift our focus from merely “getting things done” to cultivating sustainable habits and practices that nurture our overall well-being. It’s about recognizing that productivity is not a sprint but a marathon—a journey that requires us to pay equal attention to our minds, bodies, and souls.

We’ll explore the various dimensions of personal productivity, delving into topics such as calendar management, task prioritization, the use of technology, time and energy management, stress reduction, and more. By taking a holistic view, we’ll uncover strategies and techniques that empower professionals to enhance their performance not just in the workplace, but in all aspects of life.

So, join me on this journey as we embark on a quest to unlock the secrets of personal productivity and unleash our full potential in the pursuit of professional excellence.

Calendar Management:

Effective calendar management is the linchpin of personal productivity, serving as a roadmap for navigating the complexities of our professional and personal lives. It’s not merely about jotting down appointments and meetings; it’s about harnessing the power of time to achieve our goals and priorities.

Importance: Imagine a scenario where a project deadline is looming, but crucial tasks are scattered across different days or buried under a mountain of irrelevant meetings. This lack of organization can lead to missed deadlines, increased stress, and a sense of overwhelm. Conversely, with effective calendar management, we can create a clear, structured framework that ensures tasks are tackled in a timely manner, priorities are aligned, and deadlines are met.

For example, let’s consider a sales executive who has multiple client meetings, prospect calls, and follow-ups to handle in a given week. Without a well-maintained calendar, they might find themselves double-booked, forgetting important appointments, or struggling to allocate time for crucial sales activities. However, by diligently scheduling and blocking out specific time slots for each task, they can optimize their productivity, minimize conflicts, and stay on top of their game.

Tips for Organizing and Prioritizing Tasks:

- Time Blocking: Allocate dedicated time blocks for different types of activities, such as project work, meetings, email management, and breaks. This helps create a sense of focus and prevents distractions from derailing your workflow.Example: Designate the morning hours for deep work on high-priority projects, reserve afternoons for meetings and collaborative tasks, and set aside time for personal tasks or self-care activities in the evenings.

- Prioritize Tasks: Use color-coded labels or categories to distinguish between urgent, important, and non-urgent tasks on your calendar. This allows you to visually prioritize your activities and allocate time accordingly.Example: Assign a red label to critical deadlines or time-sensitive tasks, yellow for important but not urgent tasks, and green for non-urgent activities or routines.

Utilizing Calendar Tools and Applications: In today’s digital age, there is no shortage of calendar tools and applications designed to streamline and enhance our productivity. From traditional calendar apps like Google Calendar and Microsoft Outlook to more advanced project management platforms like Asana and Trello, these tools offer a plethora of features to help us manage our time more effectively.

Case Study: Consider a project manager who oversees multiple teams and complex deliverables. By leveraging project management software with integrated calendar functionality, they can create project timelines, assign tasks to team members, and track progress in real-time. This not only ensures clarity and accountability but also enables seamless coordination and communication among team members.

In conclusion, effective calendar management is not just about keeping track of appointments—it’s about optimizing our time, prioritizing tasks, and leveraging technology to work smarter, not harder. By implementing the tips and strategies outlined above, professionals can take control of their schedules, enhance their productivity, and achieve greater success in their endeavors.

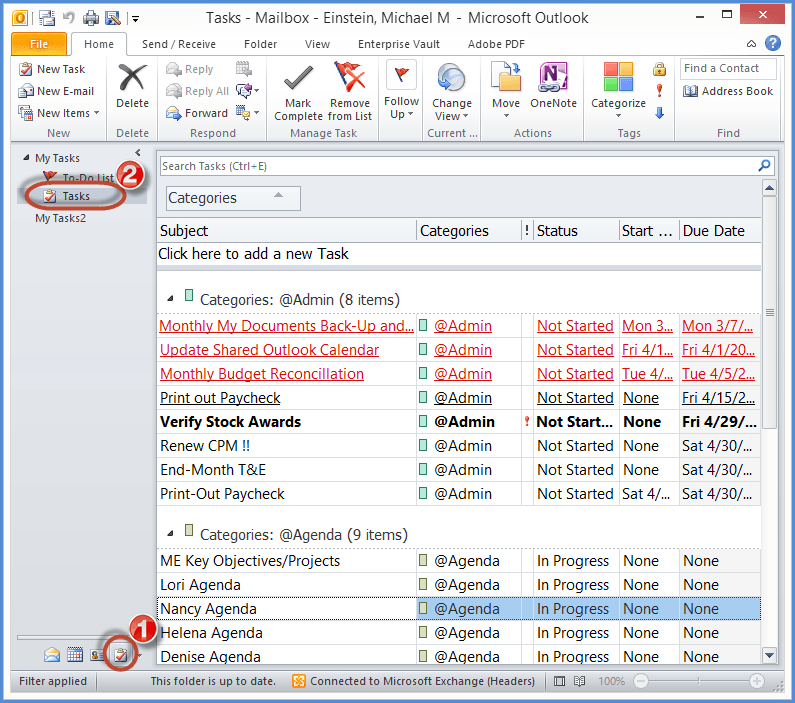

Task Management:

Task management is the cornerstone of personal productivity, serving as the foundation upon which successful projects and initiatives are built. It encompasses the process of organizing, prioritizing, and executing tasks in a systematic and efficient manner to achieve desired outcomes. Let’s explore its critical importance and effective strategies, supplemented by real-world case studies.

Importance: Imagine a scenario where a team is tasked with launching a new product within a tight deadline. Without effective task management, there’s a risk of crucial tasks slipping through the cracks, leading to delays, cost overruns, and potentially, the failure of the project. Conversely, with robust task management practices in place, teams can stay aligned, focused, and proactive, ensuring that every task is completed on time and to the desired quality standard.

In a manufacturing environment, personal productivity enhancement through effective task management is vital for individual employees to contribute efficiently to overall production goals. Here are examples of how task management techniques can be applied:

- Daily Work Plan:

- Task: Creating a daily work plan to prioritize and organize tasks for the day.

- Example: A production line operator in a manufacturing plant starts each day by reviewing the production schedule and identifying tasks to be completed, such as machine setups, material preparation, and quality checks. They use a simple checklist or digital task management tool to list tasks, prioritize them based on urgency and importance, and track progress throughout the day.

- Time Blocking:

- Task: Allocating specific time blocks for different tasks to maintain focus and productivity.

- Example: A maintenance technician in a manufacturing facility uses time-blocking techniques to allocate dedicated time slots for equipment inspections, repairs, and preventive maintenance tasks. They schedule routine maintenance activities during off-peak production hours to minimize disruption to operations and maximize productivity.

- Batch Processing:

- Task: Grouping similar tasks together and processing them in batches to improve efficiency.

- Example: A machine operator in a manufacturing plant responsible for packaging finished goods adopts batch processing techniques to streamline their workflow. Instead of packaging items one by one, they batch similar products together and package them in larger quantities, reducing setup times and increasing throughput.

- Visual Management:

- Task: Using visual cues and tools to organize tasks and monitor progress.

- Example: A warehouse supervisor in a manufacturing facility implements visual management techniques such as kanban boards or task boards to track the status of orders and inventory movement. They use color-coded cards or digital boards to represent different tasks, allowing team members to quickly identify priorities, track progress, and communicate effectively.

- Continuous Improvement:

- Task: Regularly reviewing and optimizing task management processes to identify opportunities for improvement.

- Example: A production team leader in a manufacturing plant conducts regular meetings with team members to review performance metrics, identify bottlenecks, and brainstorm solutions for process improvement. They encourage employees to suggest ideas for streamlining tasks, reducing waste, and enhancing productivity, fostering a culture of continuous improvement.

These examples demonstrate how task management techniques can be tailored to the specific needs and responsibilities of individuals working in a manufacturing environment, enabling them to enhance their personal productivity and contribute effectively to overall operational success.

Utilizing Technology in 2024:

In today’s digital age, leveraging technology is essential for optimizing workflows, increasing efficiency, and staying competitive in the manufacturing industry. With advancements in computing power, connectivity, and software capabilities, manufacturers have access to a wide array of tools and applications designed to streamline operations and enhance productivity. Let’s explore how technology can be utilized effectively, along with examples of productivity apps and software, and tips for seamless integration into daily routines.

Leveraging Technology for Streamlined Workflows:

- Automation and Robotics: Implementing automation and robotics technologies to automate repetitive tasks, increase production throughput, and improve accuracy.

- Example: A manufacturing plant installs robotic arms for assembly tasks, reducing cycle times and minimizing errors compared to manual assembly processes.

- Internet of Things (IoT): Harnessing IoT devices and sensors to monitor equipment performance, track inventory levels, and gather real-time data for predictive maintenance and process optimization.

- Example: Sensors embedded in production machinery collect data on temperature, pressure, and vibration, enabling proactive maintenance to prevent equipment failures and downtime.

- Cloud Computing: Utilizing cloud-based platforms and services for data storage, collaboration, and software-as-a-service (SaaS) applications to access tools and resources from anywhere with an internet connection.

- Example: A manufacturing company adopts cloud-based ERP (Enterprise Resource Planning) software to manage inventory, orders, and production scheduling, providing real-time visibility into operations for better decision-making.

Introduction to Productivity Apps and Software for Different Purposes:

- Project Management: Using project management software to plan, track, and coordinate tasks and resources for manufacturing projects.

- Example: Trello, Asana, or Microsoft Project for creating project timelines, assigning tasks, and monitoring progress across teams.

- Communication and Collaboration: Leveraging communication tools and collaboration platforms to facilitate real-time communication and document sharing among team members.

- Example: Slack, Microsoft Teams, or Google Workspace for instant messaging, video conferencing, and collaborative document editing.

- Time Management: Employing time tracking and task management apps to prioritize tasks, set deadlines, and track time spent on different activities.

- Example: Toggl, Todoist, or RescueTime for tracking work hours, managing tasks, and analyzing productivity trends.

Tips for Integrating Technology Seamlessly into Daily Routines:

- Training and Education: Receive training and ongoing support to familiarize with new technologies and ensure effective utilization.

- Start Small: Begin with pilot projects or small-scale implementations to test technology solutions before scaling up to larger deployments.

- Customization and Integration: Customize software solutions to meet specific business needs and integrate them with existing systems for seamless data exchange and workflow automation.

By embracing technology and adopting the right tools and applications, manufacturers can streamline workflows, increase productivity, and gain a competitive edge in today’s rapidly evolving market landscape.

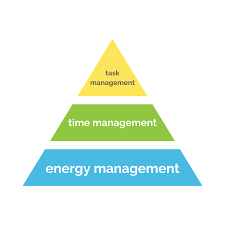

Time and Energy Management:

Understanding the Difference: Time management focuses on how we allocate and prioritize our time to accomplish tasks and achieve goals. It’s about being efficient and effective in our use of time, minimizing distractions, and maximizing productivity. On the other hand, energy management revolves around managing our physical, mental, and emotional energy levels to sustain focus, creativity, and motivation throughout the day. It’s about recognizing that our energy is finite and fluctuates, and leveraging strategies to optimize and replenish it as needed.

Techniques for Optimizing Energy Levels:

- Strategic Breaks: Take regular breaks throughout the day to rest and recharge. Short breaks between tasks can help prevent burnout and maintain energy levels.Example: A software developer incorporates the Pomodoro Technique, taking short breaks every 25 minutes of focused work to stretch, hydrate, and rejuvenate before diving back into the next task.

- Power Naps: Incorporate short power naps during the day to combat fatigue and enhance alertness and cognitive function.Example: A nurse working night shifts takes a 20-minute power nap during their break to replenish energy levels and stay alert during demanding patient care duties.

Balancing Workload with Personal Energy Levels:

- Task Prioritization: Align high-energy tasks requiring focus and creativity with times of the day when energy levels are at their peak.Example: A marketing manager schedules brainstorming sessions and creative strategy planning in the morning when their energy and cognitive function are highest, reserving routine administrative tasks for the afternoon slump.

- Energy-Boosting Activities: Incorporate activities that replenish and boost energy levels throughout the day, such as exercise, mindfulness practices, and healthy nutrition.Example: A factory worker takes a brisk walk during their lunch break to get some fresh air, increase blood flow, and rejuvenate both body and mind for the afternoon shift.

Mental and Emotional Well-being:

Importance of Mental and Emotional Health in Productivity: Maintaining mental and emotional well-being is essential for sustaining high levels of productivity, creativity, and resilience in the workplace. When individuals are mentally and emotionally healthy, they experience greater focus, motivation, and job satisfaction, leading to improved performance and overall organizational success.

Strategies for Managing Stress and Anxiety in the Workplace:

- Stress Awareness: Recognize and acknowledge signs of stress and anxiety, such as increased irritability, difficulty concentrating, and physical symptoms like headaches or muscle tension.Example: A project manager attends stress management workshops and practices self-awareness techniques to identify triggers and early warning signs of stress, proactively implementing coping strategies before it escalates.

- Stress Reduction Techniques: Incorporate stress reduction techniques into daily routines, such as deep breathing exercises, meditation, and progressive muscle relaxation.Example: An HR professional practices mindfulness meditation for 10 minutes each morning before starting work, cultivating a sense of calmness and mental clarity to navigate the demands of the workday with greater resilience.

Incorporating Mindfulness and Resilience-Building Practices:

- Mindfulness Meditation: Cultivate mindfulness through regular meditation practice, fostering present-moment awareness, acceptance, and non-judgmental observation of thoughts and emotions.Example: A sales executive attends weekly mindfulness sessions offered by the company, learning techniques to manage stress, improve focus, and enhance emotional regulation in high-pressure sales situations.

- Resilience Training: Participate in resilience-building workshops and training programs to develop skills for bouncing back from setbacks, adapting to change, and thriving in challenging environments.Example: An IT professional participates in resilience training sessions to enhance their ability to cope with project setbacks, technical challenges, and tight deadlines, fostering a positive and resilient mindset for navigating the dynamic IT landscape.

By prioritizing mental and emotional well-being, individuals can cultivate a healthy and supportive work environment, fostering creativity, collaboration, and organizational success.

Stress Management in a Manufacturing Professional Perspective:

Identifying Sources of Stress in the Professional Environment:

- Production Deadlines: Tight production deadlines and quotas can create immense pressure on manufacturing professionals to meet targets, leading to stress and anxiety.Example: A production manager in a manufacturing plant faces stress due to the pressure to meet monthly production targets while ensuring quality standards and minimizing downtime.

- Equipment Failures: Unexpected breakdowns or malfunctions of machinery and equipment can disrupt production schedules and increase stress levels for maintenance staff and production workers.Example: A maintenance technician experiences stress when a critical machine breaks down unexpectedly, requiring immediate troubleshooting and repair to minimize production delays.

Coping Mechanisms and Relaxation Techniques to Alleviate Stress:

- Deep Breathing Exercises: Practicing deep breathing exercises can help reduce stress and promote relaxation by calming the nervous system and lowering cortisol levels.Example: A machine operator takes a few minutes during breaks to practice deep breathing exercises, inhaling deeply through the nose and exhaling slowly through the mouth to release tension and reset their mindset.

- Progressive Muscle Relaxation: Progressive muscle relaxation involves tensing and relaxing different muscle groups in the body to promote physical and mental relaxation.Example: A production line worker practices progressive muscle relaxation techniques during lunch breaks, systematically tensing and relaxing muscles from head to toe to release built-up tension and stress from repetitive tasks.

Establishing Healthy Boundaries and Self-care Routines:

- Setting Realistic Expectations: Setting realistic expectations and boundaries regarding workload and responsibilities can help prevent burnout and manage stress levels.Example: A shift supervisor communicates with upper management about realistic production targets and resource constraints, advocating for achievable goals that prioritize employee well-being and safety.

- Prioritizing Self-care: Prioritizing self-care activities such as exercise, hobbies, and socializing outside of work can help manufacturing professionals recharge and replenish their energy reserves.Example: A quality control inspector engages in regular exercise routines and hobbies such as gardening or painting after work to unwind and decompress from the stresses of the job, fostering a healthy work-life balance.

Case Study: A manufacturing engineer working in a high-pressure automotive assembly plant experiences chronic stress due to tight project deadlines, demanding production schedules, and technical challenges. To cope with stress, the engineer implements a holistic approach to stress management, including regular exercise, mindfulness meditation, and seeking support from colleagues and mentors. By prioritizing self-care and implementing stress reduction techniques, the engineer improves resilience, enhances job satisfaction, and maintains peak performance in a challenging manufacturing environment.

Stress management is essential for maintaining well-being and productivity in the manufacturing industry. By identifying sources of stress, implementing coping mechanisms and relaxation techniques, and establishing healthy boundaries and self-care routines, manufacturing professionals can effectively manage stress and thrive in their professional roles.

++++

In conclusion,

We’ve explored the holistic approach to personal productivity, delving into various aspects such as time and energy management, mental and emotional well-being, and stress management in the context of the manufacturing industry. Here are the key takeaways:

- Balancing Time and Energy: Effective time and energy management are essential for sustaining productivity and well-being. By prioritizing tasks, optimizing energy levels, and integrating relaxation techniques, professionals can achieve a harmonious balance between productivity and personal wellness.

- Addressing Stress: Stress is inevitable in the manufacturing environment, but it can be managed effectively. By identifying sources of stress, implementing coping mechanisms, and establishing healthy boundaries, professionals can mitigate its impact and thrive amidst challenges.

- Prioritizing Well-being: Mental and emotional well-being is paramount for sustained performance and job satisfaction. Prioritizing self-care, setting realistic expectations, and fostering a supportive work environment are crucial for maintaining overall well-being.

- Continuous Improvement: Personal productivity is a journey of continuous improvement. Professionals are encouraged to experiment with different strategies, seek feedback, and adapt their approach to find what works best for them.

In closing, I encourage professionals in the manufacturing industry to prioritize their personal productivity and well-being. By implementing the strategies discussed and embracing a holistic approach, you can enhance your performance, resilience, and satisfaction in your professional endeavors. Remember, investing in yourself is not only beneficial for your career but also for your overall quality of life. Here’s to a future of productivity, balance, and fulfillment in the manufacturing sector.

Karthik

18/5/24 12 Noon.