#186

I reproduce an email message sent to the plant managers with whom I interact on regular basis.

Introduction

Dear Plant Managers,

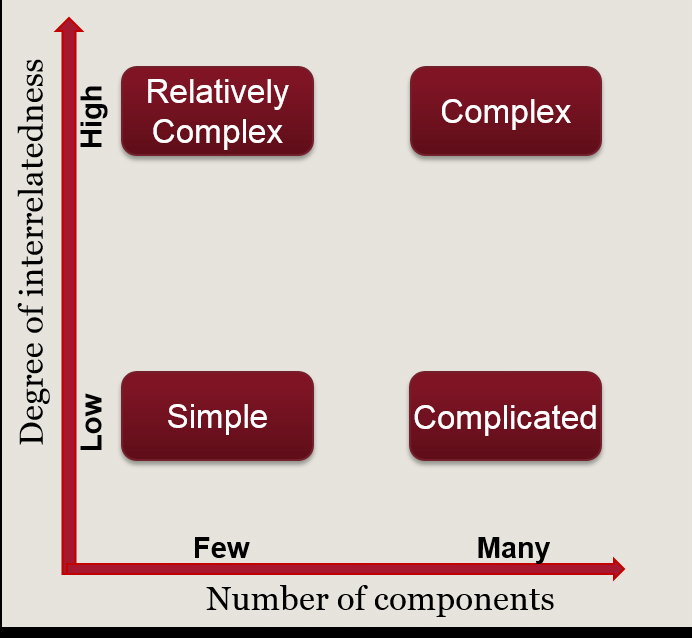

In our ongoing efforts to enhance safety and operational efficiency, it’s critical to understand the nature of the systems we work with daily. Systems can be categorized as simple, complicated, or complex. Recognizing the differences between these types is essential for implementing effective control measures to prevent incidents and process excursions.

Simple Systems

Characteristics:

- Predictable and Repeatable: Simple systems operate in a straightforward manner, with clear cause-and-effect relationships.

- Easily Managed: Procedures are often well-documented, and outcomes are consistent.

Example:

- Valve Operation: Opening and closing a valve to control the flow of a liquid. The procedure is well-defined, and the results are predictable.

Control Measures:

- Standard Operating Procedures (SOPs): Clear, written instructions for operations.

- Training and Competency: Regular training sessions to ensure all operators are proficient in the tasks.

- Routine Inspections: Regular checks to ensure the equipment is functioning correctly.

Complicated Systems

Characteristics:

- Multiple Components: These systems involve several interconnected parts, each of which may be simple but together create complexity.

- Expertise Required: Requires specialized knowledge to understand and manage.

Example:

- Distillation Column Operation: Involves controlling various parameters such as temperature, pressure, and feed composition to separate chemical components.

Control Measures:

- Detailed Documentation: Comprehensive manuals and documentation for all procedures and troubleshooting steps.

- Expert Training: Specialized training for operators and engineers to handle specific tasks.

- Preventive Maintenance: Regular maintenance schedules to ensure all components are in optimal condition.

Complex Systems

Characteristics:

- Dynamic and Unpredictable: These systems have many interacting elements and can behave in unpredictable ways.

- Non-linear Relationships: Small changes can have disproportionate effects on the outcome.

Example:

- Chemical Reaction in a Reactor: Involving multiple reagents and reaction pathways, where slight variations in conditions can lead to different products or even hazardous situations.

Control Measures:

- Real-Time Monitoring: Advanced sensors and monitoring systems to provide real-time data on system performance.

- Automated Controls: Automation to quickly adjust parameters and maintain stability.

- Risk Assessments: Regular risk assessments and scenario planning to anticipate and mitigate potential issues.

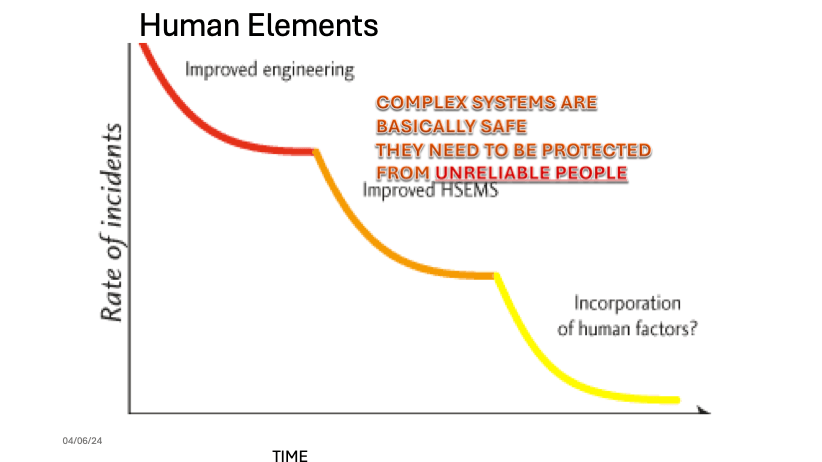

Highly Complex Systems and Human Reliability

Challenges:

- Unreliability of Human Operators: In highly complex systems, the potential for human error increases due to the intricate nature of the system and the cognitive load on operators.

Example:

- Nuclear Power Plant Operations: Managing a nuclear reactor requires precise control and understanding of numerous variables, with significant consequences for any errors.

Control Measures:

- Fail-Safe Mechanisms: Design systems to default to a safe state in case of failure.

- Redundancy: Implement redundant systems to provide backups in case of primary system failure.

- Human-Machine Interfaces (HMIs): Develop intuitive and user-friendly interfaces to reduce the cognitive load on operators.

- Simulation Training: Use advanced simulators for training operators in handling various scenarios, including emergencies.

Conclusion

Understanding the nature of the systems we manage is crucial for ensuring safety and efficiency. By recognizing whether a system is simple, complicated, or complex, we can implement the appropriate control measures to mitigate risks and prevent incidents. In highly complex systems, it’s particularly important to design processes that protect the system from human errors, ensuring robust and reliable operations.

++++++++++++++++++++

Why Engineering Controls Followed by Management Systems Implementation is the Best Approach to Reduce Incidents

Introduction

Ensuring the safety and efficiency of our operations is paramount. One effective strategy is prioritizing engineering controls, followed by robust management systems implementation, with people intervention as the last line of defense. This hierarchy of controls approach is essential for reducing incidents and maintaining process stability.

Hierarchy of Controls Explained

The hierarchy of controls is a systematic approach to minimizing or eliminating hazards. It ranks control measures by their effectiveness, from the most effective (engineering controls) to the least (administrative controls and personal protective equipment). Here’s why this approach is crucial:

1. Engineering Controls

Definition: Engineering controls involve designing or modifying equipment and processes to reduce exposure to hazards.

Why They Are Effective:

- Inherent Safety: Engineering controls eliminate or reduce hazards at the source, offering a permanent solution.

- Reliability: These controls do not rely on human intervention, which can be prone to error.

- Consistency: They provide consistent protection without requiring user compliance.

Examples:

- Guarding Machinery: Installing physical barriers to protect operators from moving parts.

- Ventilation Systems: Using exhaust systems to remove harmful vapors or dust from the work environment.

- Automation: Implementing automated systems to handle dangerous tasks, reducing human exposure to risks.

2. Management Systems

Definition: Management systems involve structured frameworks and procedures to ensure safety and efficiency.

Why They Are Effective:

- Organizational Control: Management systems provide a structured approach to managing risks and ensuring compliance with safety standards.

- Continuous Improvement: They include mechanisms for continuous monitoring, review, and improvement of safety practices.

- Accountability: These systems assign clear responsibilities and accountability for safety, ensuring everyone knows their role in maintaining a safe workplace.

Examples:

- Safety Management Systems (SMS): A comprehensive framework that integrates safety into all aspects of operations, including risk assessment, incident reporting, and training.

- Quality Management Systems (QMS): Ensuring processes are followed correctly and consistently to maintain product and operational quality.

- Environmental Management Systems (EMS): Managing environmental risks and ensuring compliance with environmental regulations.

3. People Intervention

Definition: People intervention involves actions taken by individuals, often relying on training, adherence to procedures, and the use of personal protective equipment (PPE).

Why They Are Less Effective:

- Human Error: People can make mistakes, especially under stress or when tired, leading to potential safety incidents.

- Inconsistency: Reliance on individuals to follow procedures perfectly every time can lead to variability and gaps in safety.

- Behavioral Factors: Attitudes, motivations, and perceptions can affect how well safety procedures are followed.

Examples:

- Training Programs: Regular training sessions to ensure workers understand and follow safety procedures.

- Personal Protective Equipment (PPE): Providing and requiring the use of safety gear like helmets, gloves, and eye protection.

- Safety Protocols: Implementing detailed safety protocols that workers must follow.

Why Engineering Controls and Management Systems Are Superior

Long-Term Effectiveness:

- Engineering controls offer permanent solutions that do not degrade over time, while management systems ensure ongoing adherence to safety practices.

Reduced Reliance on Human Behavior:

- By minimizing the need for human intervention, we reduce the likelihood of errors and variability in safety performance.

Sustainability:

- Engineering controls and management systems are designed to integrate seamlessly into operations, ensuring sustained safety improvements.

Cost Efficiency:

- While initial investments in engineering controls and management systems may be higher, they often result in long-term savings by preventing incidents and reducing downtime.

Conclusion

Prioritizing engineering controls, followed by implementing robust management systems, is the most effective strategy for reducing incidents and ensuring process safety. This approach minimizes the reliance on human intervention, providing a more reliable and sustainable solution to managing hazards. By adhering to this hierarchy of controls, we can create a safer, more efficient workplace.

Regards

Karthik

4th June 2024. 11am.