#198

Introduction: The Ubiquity of Human Error

Human error is an unavoidable aspect of life that permeates every field, from aviation and manufacturing to healthcare and daily activities. As fallible beings, humans are prone to making mistakes, whether due to cognitive limitations, environmental factors, or simple lapses in attention. Organizations must recognize that errors are an inherent part of human behavior and plan accordingly to mitigate their impacts.

In complex, high-stakes environments like manufacturing and aviation, the consequences of human error can be severe, leading to costly incidents, safety hazards, and even loss of life. However, errors are not confined to these sectors alone; they occur in all walks of life. From miscommunications in personal relationships to financial mistakes in everyday transactions, the potential for error is ever-present.

Understanding that human error is common allows organizations to adopt a proactive approach to risk management. This involves designing systems and processes that anticipate mistakes, incorporating checks and balances, and fostering a culture of continuous learning and improvement. By acknowledging the inevitability of human error and implementing robust preventive measures, organizations can enhance safety, efficiency, and overall performance, turning potential vulnerabilities into opportunities for growth and resilience.

Here are a couple of major incidents in aviation and manufacturing that occurred due to human error:

Aviation Incidents

1. Tenerife Airport Disaster (1977)

- Overview: The Tenerife Airport disaster is the deadliest aviation accident in history, resulting in 583 fatalities. It occurred on March 27, 1977, at Los Rodeos Airport (now Tenerife North Airport) in the Canary Islands.

- Human Error: A series of miscommunications and misunderstandings between the flight crews and air traffic control led to the collision of two Boeing 747 aircraft on the runway. Factors included:

- Language and Radio Communication: Ambiguous language used during radio communications.

- Misinterpretation: The KLM flight captain misunderstood air traffic control instructions and began takeoff without clearance.

- Environmental Factors: Dense fog reduced visibility, preventing the crews from seeing each other until it was too late.

2. Air France Flight 447 (2009)

- Overview: Air France Flight 447 crashed into the Atlantic Ocean on June 1, 2009, killing all 228 passengers and crew members on board.

- Human Error: The primary cause was pilot error during a stall situation:

- Failure to Correct Stall: The aircraft’s autopilot disconnected due to inconsistent airspeed readings, and the pilots failed to recognize and properly respond to the stall.

- Lack of Coordination: Poor communication and coordination between the pilots contributed to the failure to regain control of the aircraft.

Manufacturing Incidents

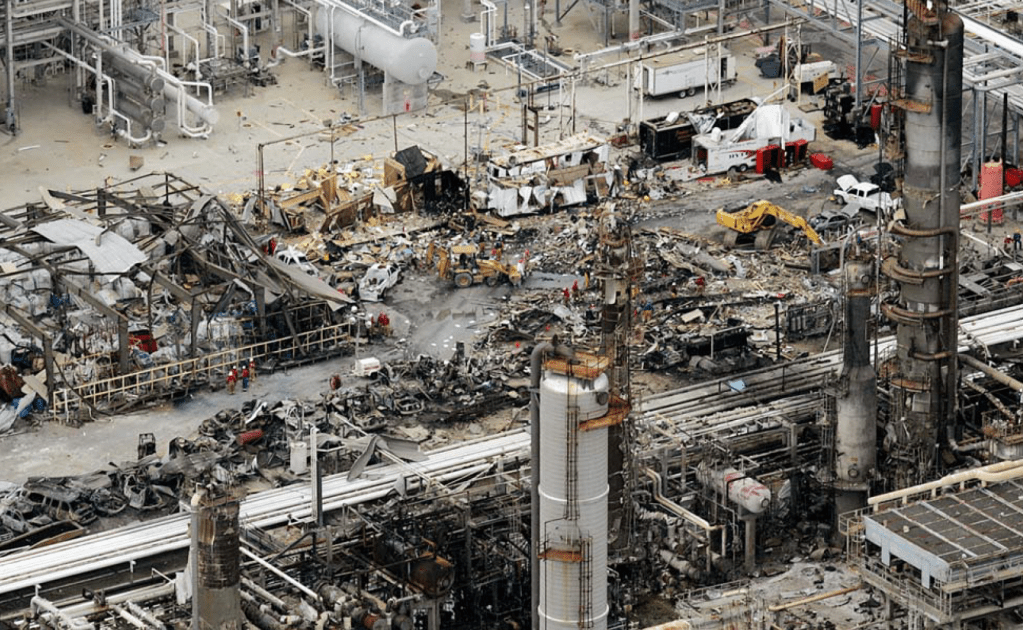

1. Texas City Refinery Explosion (2005)

- Overview: On March 23, 2005, an explosion occurred at the BP refinery in Texas City, Texas, resulting in 15 deaths and over 170 injuries.

- Human Error: The explosion was caused by a series of procedural lapses and human errors:

- Inadequate Procedures: The start-up procedures were not followed correctly, leading to overfilling and overheating of a distillation tower.

- Safety System Failures: The alarms and safety systems failed to alert the operators to the dangerous conditions in time.

- Lack of Training: Insufficient training and inadequate understanding of the process among the operators.

These examples highlight the critical role of human factors in safety and the importance of rigorous training, clear communication, and adherence to procedures to prevent such tragic incidents. Understanding these past errors helps industries implement better safety measures and cultivate a culture of continuous improvement to mitigate risks associated with human error.

Understanding and Mitigating Human Error in Manufacturing

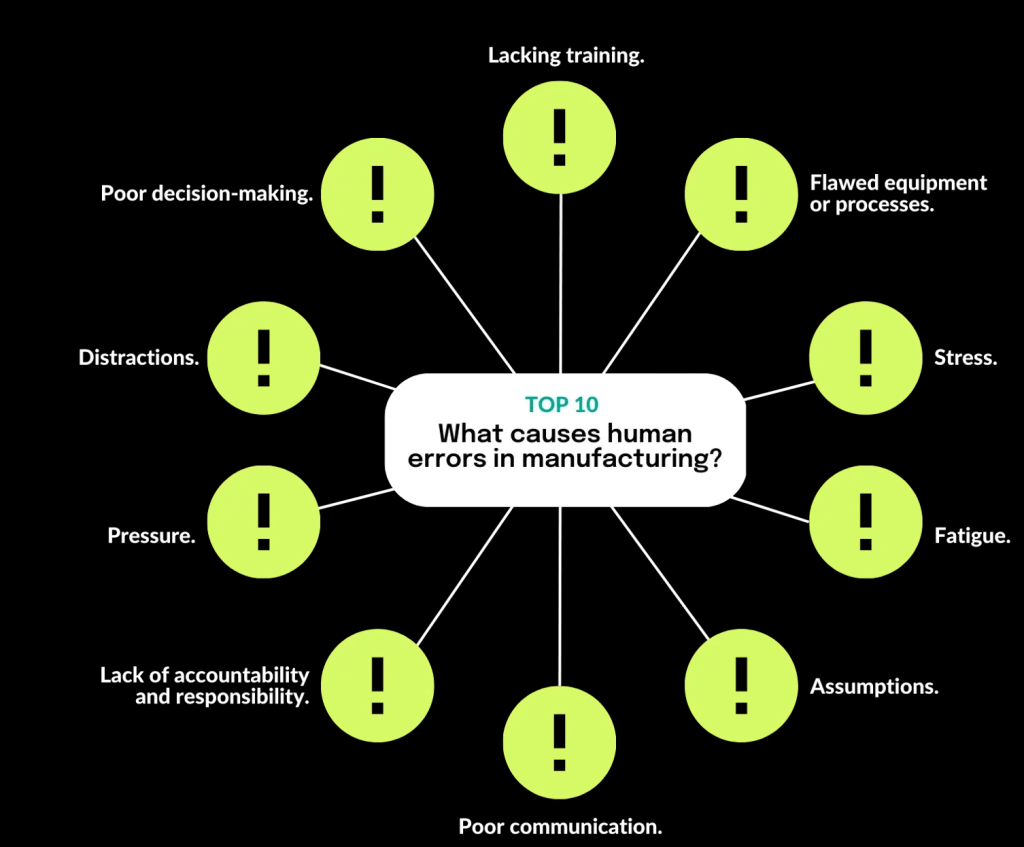

Human error in manufacturing can lead to significant issues, from minor quality defects to major safety incidents. Understanding the types of memory failures and errors that occur, and implementing effective interventions, is crucial for mitigating these risks and enhancing overall performance.

Types of Memory Failures

- Short-term Memory Failures: This type of failure happens when information is not retained long enough to be used. In a manufacturing context, this could lead to an operator forgetting a crucial step in a process shortly after being told about it.

- Long-term Memory Failures: This involves the inability to recall information that was previously known. For example, a worker may forget the proper maintenance procedures for equipment that they were trained on several months ago.

- Prospective Memory Failures: This refers to forgetting to perform a planned action. In manufacturing, this could mean an operator forgetting to switch off a machine after completing a task.

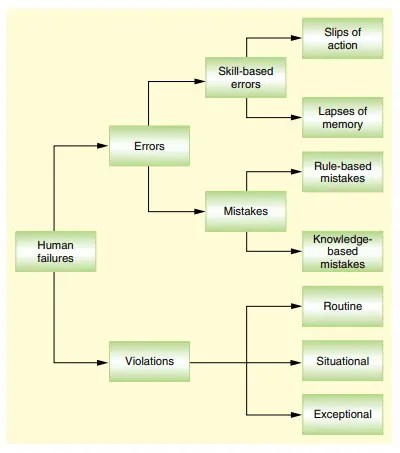

Understanding Errors and Lapses

- Slips: These are actions that do not go as intended, often due to distractions or lapses in attention. For instance, pressing the wrong button on a control panel.

- Lapses: These are failures of memory, such as forgetting to complete a step in a process. Lapses are often caused by stress, fatigue, or a high workload.

- Mistakes: These occur when an action goes as planned but the plan itself is flawed. Mistakes are usually due to a lack of knowledge or experience, leading to incorrect decisions.

- Violations: These are deliberate deviations from established procedures, often due to perceived pressure to meet deadlines or other performance metrics.

Active Errors and Unintended Errors

- Active Errors: These errors occur at the point of interaction between humans and systems. They are usually immediately apparent and can have instant consequences. Examples include an operator accidentally pressing the wrong button or a technician misconnecting a wire. Active errors are typically the result of direct human actions.

- Unintended Errors: These are errors that occur without any deliberate intent to deviate from procedures. They can be the result of slips, lapses, or even external factors like poor lighting or loud noise. Unintended errors are often subtle and can go unnoticed until they cause a problem, such as a worker misreading a gauge due to fatigue.

Impact on Manufacturing Performance

Human errors can result in:

- Quality Issues: Defective products due to incorrect processes or missed steps.

- Safety Incidents: Accidents caused by improper use of equipment or failure to follow safety protocols.

- Productivity Losses: Delays and downtime resulting from mistakes that need to be corrected.

- Financial Costs: Increased costs from rework, scrap, and potential regulatory fines.

Interventions to Mitigate Human Error

- Technology and Systems:

- Automation: Use automated systems to handle repetitive and complex tasks, reducing reliance on human memory and minimizing errors.

- Error-proofing (Poka-Yoke): Implement devices and procedures that prevent errors before they occur. For example, designing equipment that only fits together one way.

- Training:

- Continuous Training Programs: Regularly update training programs to reinforce proper procedures and introduce new practices.

- Simulation-Based Training: Use simulations to create realistic scenarios where employees can practice handling unexpected situations without real-world consequences.

- Communication:

- Clear Instructions: Ensure that all instructions are clear, concise, and easy to understand.

- Feedback Loops: Establish systems where employees can provide feedback on processes and report potential issues without fear of retribution.

- Ownership and Accountability:

- Empower Employees: Encourage workers to take ownership of their tasks and understand the impact of their actions on overall performance.

- Accountability Structures: Implement systems where accountability is shared among team members, reducing the likelihood of blame-shifting.

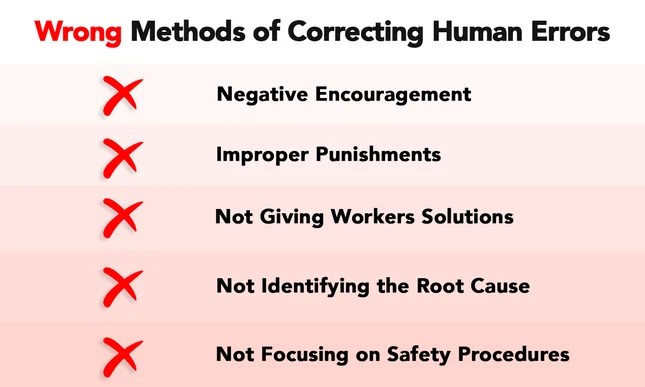

- Changing the Narrative Around Mistakes:

- Learning Culture: Foster a culture where mistakes are seen as opportunities for learning and improvement rather than reasons for punishment.

- Root Cause Analysis: Focus on identifying and addressing the root causes of errors rather than merely treating symptoms.

- Standard Operating Procedures (SOPs):

- Regular Reviews: Ensure SOPs are regularly reviewed and updated to reflect current best practices and technologies.

- Visual Aids: Use diagrams, flowcharts, and other visual aids to make SOPs more accessible and easier to follow.

Additional Interventions and Strategies

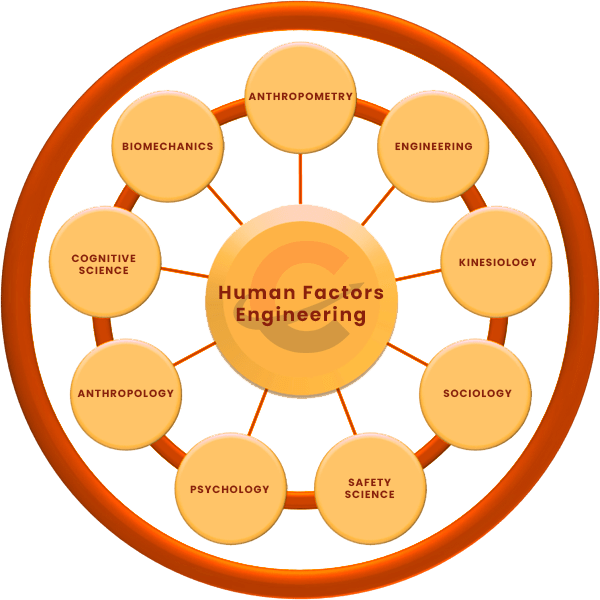

- Ergonomics and Human Factors Engineering:

- Workspace Design: Ensure that workstations are designed to minimize physical strain and reduce the likelihood of errors. Proper lighting, comfortable seating, and easy access to tools can all contribute to better performance.

- Human-Machine Interface: Design control panels and interfaces to be user-friendly, reducing the likelihood of operator errors. Clear labeling and intuitive layouts can make a significant difference.

- Environmental and Organizational Factors:

- Work Environment: Maintain a clean, well-organized, and safe work environment. Reducing clutter and hazards can help employees focus better and reduce the likelihood of accidents.

- Shift Management: Implement effective shift management practices to reduce fatigue. Consider rotating shifts and ensuring adequate rest periods to keep workers alert and focused.

- Psychological and Cognitive Approaches:

- Mindfulness and Stress Reduction: Offer programs that teach stress management and mindfulness techniques. Reducing stress can improve focus and reduce errors.

- Mental Models and Cognitive Training: Provide training that helps employees develop accurate mental models of the systems they work with. Understanding the underlying principles of equipment and processes can help in troubleshooting and error prevention.

- Advanced Technology Interventions:

- Predictive Analytics and AI: Use predictive analytics to anticipate equipment failures and perform maintenance before issues arise. This can prevent errors related to equipment malfunction.

- Artificial Intelligence: Implement AI systems to monitor processes in real-time and provide alerts or corrective actions when deviations occur.

- Digital Tools: Use augmented reality (AR) tools to provide real-time guidance and information overlays for complex tasks. Equip workers with wearable technology that can monitor their physiological signs and alert them or supervisors if signs of fatigue or stress are detected.

- Cultural and Behavioral Approaches:

- Leadership Commitment: Ensure that leadership is committed to a culture of safety and continuous improvement. Visible support from management can reinforce the importance of error prevention.

- Behavioral Safety Programs: Implement programs that focus on safe behaviors and recognize employees for following safety protocols and reporting potential hazards.

- Engagement and Involvement: Involve employees in safety and process improvement initiatives. Engaged employees are more likely to follow procedures and contribute to a safer workplace.

- Peer Reviews and Support: Encourage peer reviews and support systems where workers can check each other’s work and provide constructive feedback.

- Continuous Improvement and Feedback Loops:

- Data-Driven Decisions: Maintain a robust system for tracking incidents and near-misses. Analyze this data to identify trends and implement corrective actions. Use real-time monitoring systems to continuously assess processes and identify potential issues before they result in errors.

- Learning and Adaptation: After an error occurs, conduct thorough investigations to understand what happened and why. Share these lessons across the organization to prevent recurrence. Regularly update SOPs based on feedback and new insights, ensuring that these updates are communicated clearly to all employees.

Conclusion

Understanding and mitigating human error in manufacturing is crucial for enhancing safety, efficiency, and overall performance. By recognizing the types of errors and memory failures that can occur, and implementing a range of interventions—from advanced technology and training to fostering a culture of accountability and continuous improvement—organizations can significantly reduce the risk of incidents.

Active errors and unintended errors are part of the human experience, but with the right strategies, their impact can be minimized. Emphasizing clear communication, robust standard operating procedures, ergonomic design, and psychological support creates a safer and more productive work environment. Ultimately, a proactive approach to human error not only protects workers and enhances quality but also fosters a culture where learning from mistakes leads to continuous advancement and success.

Karthik

5th July 2024. (Eve of Piper Alpha Disaster). 1500 Hrs.

Piper Alpha Memorial.

Opened by Queen Mother.