#200

Reaching my 200th blog post is a significant milestone, marking eight years of sharing insights and experiences in the field of Environmental Health and Safety (EHS). Throughout this journey, I’ve seen firsthand how critical it is to maintain vigilance, even when performance indicators seem very favorable. Today, I want to discuss why excellent EHS or operational performance can sometimes lead to complacency and how to guard against it.

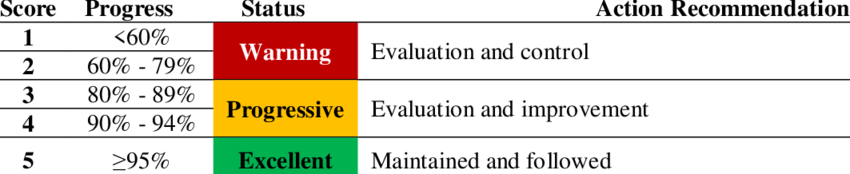

In Environmental Health and Safety (EHS) and operational excellence, green, yellow, and red indicators (Traffic Light) are commonly used in dashboards to quickly communicate the status of various metrics and key performance indicators (KPIs). Here’s what each color typically signifies:

Green Indicators

Meaning:

- Status: Everything is running smoothly.

- Performance: Meeting or exceeding targets.

- Risk Level: Low risk, under control.

Implications:

- Indicates that the processes or systems are functioning well.

- Signals that the objectives are being met without significant issues.

- Can sometimes lead to complacency if not regularly scrutinized for hidden problems.

Example:

- An EHS dashboard showing zero incidents or accidents for a sustained period.

Yellow Indicators

Meaning:

- Status: Caution or warning.

- Performance: Slightly below target or starting to show potential issues.

- Risk Level: Medium risk, needs attention.

Implications:

- Suggests that there are areas requiring improvement.

- Indicates that processes might be starting to struggle and need intervention to prevent escalation to red.

- Calls for proactive measures to address and resolve underlying issues.

Example:

- An increase in near-miss incidents or minor safety violations that haven’t yet resulted in accidents.

Red Indicators

Meaning:

- Status: Critical or failing.

- Performance: Significantly below target.

- Risk Level: High risk, immediate action required.

Implications:

- Signals that there are major issues or failures that need urgent attention.

- Indicates serious problems that could lead to significant negative consequences if not addressed promptly.

- Often requires a deep dive to understand root causes and implement corrective actions.

Example:

- A severe accident or incident that results in injuries, fatalities, or significant operational disruption.

+++++++++++++++++++++++++++++++++++++++++++++++

1. Be Skeptical of Green Indicators

When dashboards consistently show green, it’s easy to assume everything is running smoothly. However, green indicators should not be taken at face value. In fact, prolonged periods without issues can sometimes mask underlying problems. Remember, no news for a while can be bad news. A green dashboard might indicate that issues are not being reported or detected rather than their absence.

Consider the Deepwater Horizon disaster—an event that occurred when everything appeared to be green. Complacency had set in, and ironically, they were celebrating a safety milestone when the blowout happened. This tragic incident serves as a stark reminder that green indicators are not always a guarantee of safety.

Key Takeaway: Apply the philosophy of “Trust but verify.” Regularly scrutinize green indicators (With a bit of skeptiscm) by checking random aspects of the metrics in detail. Like Tim Cook and Steve Jobs, probe so deeply that your directs might struggle to answer and, as a result, you come up with ideas for improvement. This approach ensures you truly understand the situation and can offer expert guidance for improvement.

2. Dive Deep into Yellow Indicators

Yellow indicators signal caution—they suggest that processes or programs are struggling. This is where your intervention is most crucial. Rather than waiting for these indicators to turn red, proactive engagement can help address the underlying issues.

Key Takeaway: Invest time in understanding why an indicator is yellow. Work closely with the people involved to identify challenges and provide the necessary support to turn these indicators green. Success in these areas often requires collaboration, problem-solving, and resource allocation.

3. Understand and Contemplate the Red Indicators

Red indicators are clear signals that something is fundamentally wrong. However, it’s vital to approach these situations without assigning blame. Often, these issues stem from deeper problems such as managerial faults, incorrect approaches, or systemic flaws.

Key Takeaway: When facing red indicators, focus on understanding the root causes rather than blaming individuals. Conduct thorough investigations to identify the real issues, and work collaboratively to develop effective solutions. Seek expertise help. This approach not only resolves the immediate problem but also strengthens the overall EHS / Operational culture.

The Denial Mode: A Dangerous Pitfall

Many organizations celebrate their green indicators, often becoming complacent and ignoring potential risks. This complacency can lead to a state of denial, where teams are shocked and unprepared when things go wrong. In today’s age of disenchantment, disengagement, and dejection among 80% of the organisational workforce, it’s more important than ever to take green indicators with a pinch of skepticism.

Key Takeaway: Foster a culture of continuous improvement. Encourage teams to remain vigilant and proactive, even when performance appears optimal. Recognize that true safety and operational excellence require ongoing effort and attention. It is a journey, not a destination.

Real-World Reminders

The Deepwater Horizon disaster is not an isolated incident. There have been other examples where things burst out when everything appeared quiet. These events highlight the importance of maintaining a critical eye and never letting complacency take root, regardless of how green the dashboard looks.

In conclusion, while green indicators are a positive sign, they should not lead to complacency. By being skeptical, proactive, and understanding, we can ensure that EHS and operational performance remains robust and resilient. Here’s to many more years of learning, growing, and improving together.

Thank you all for your support and encouragement. I request you to subscribe to my blog so that an Email comes to your Inbox, as and when I update this blog page.

Karthik.

12th July 2024 1130am.