#208

It is with a heavy heart that I reflect on two recent process safety accidents in India’s hazardous chemical manufacturing sector. The loss of 20 lives, and 40 injured—many facing lifelong disabilities—is tragic beyond words. In both incidents, a solvent leak from an unattended process reaction led to an unconfined vapor cloud explosion in an Active Pharmaceutical Ingredient (API) manufacturing plant, while another disaster resulted from a fire ignited by static electricity hazards. These accidents claimed the lives of average middle-class Indians, many of whom were the sole breadwinners for their families, making this loss even more devastating.

These events, while shocking, are not isolated incidents. Accidents like these are the unfortunate result of multiple, overlapping failures in process safety management. But the core of this problem is the larger systemic breakdown in India’s regulatory framework for hazardous chemical manufacturing.

The Regulatory Gaps: Weak Laws, Poor Enforcement

India’s regulatory environment for process safety is distressingly lax. The guidelines and rules governing chemical process safety are unclear, vague, and poorly implemented. Even when the rules exist, enforcement is rare due to overburdened regulatory agencies. With an estimated 60:1 industry-to-regulator ratio, how can we expect proper oversight? Understaffed agencies can barely cope with the demands of the sector, let alone proactively address process safety violations.

Fines and penalties are too insignificant to act as a deterrent. In some cases, the financial penalties issued after a fatal incident are so minor they would barely register as a rounding error in a company’s balance sheet.

The Skills Gap: Are We Prepared?

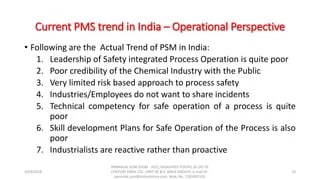

Beyond regulations, a critical factor is the skill and competence of workers and facilities in recognizing hazards, remediating risks, and ensuring rigorous participation in operational safety protocols. Too often, facilities lack comprehensive hazard identification programs. Many employees are under-trained or inadequately educated in the risks associated with their roles.

A facility’s ability to prevent accidents isn’t just about having robust engineering controls or state-of-the-art equipment. It’s about creating a culture of safety that permeates every level of the organization—from top management to the shop floor. Middle management commitment to loss prevention is particularly critical, yet it often gets overlooked. If supervisors and plant managers do not champion a questioning attitude toward safety protocols, small hazards that could be easily addressed will evolve into catastrophic failures.

A Call for Ownership: Industry Must Step Up

Industries, from local plants to multinational corporations, must take ownership of process safety. This is not just a regulatory requirement; it’s a moral and ethical responsibility. The death of workers due to preventable accidents is unacceptable, and companies must realize that safety should never be sacrificed for profit.

Here are some key areas that need immediate attention:

- Collaborative Safety Initiatives: Industries should fund and contribute to nationwide or regional chemical safety programs that are aimed at accident prevention. These programs could include technical expertise, shared best practices, and collaborative safety audits to ensure that lessons learned in one facility are applied across the sector.

- Mandatory Safety Guidelines: Industry associations should work together with regulatory bodies to develop and enforce clear, mandatory guidelines. These must be implemented uniformly across regions and audited rigorously. They should be endorsed by regulators and backed with severe penalties for non-compliance.

- Employee Training and Participation: A process safety culture thrives when employees are empowered and trained to identify hazards, understand operational risks, and participate in safety protocols. This isn’t just about compliance—it’s about building a workforce that prioritizes safety and takes an active role in accident prevention.

- Transparency and Open-Source Hazard Data: The industry must work toward greater transparency in sharing data on process hazards. A public, open-source repository of hazards, incidents, and best practices would benefit the entire sector, allowing companies to learn from each other’s experiences. Too often, valuable lessons from tragic accidents are buried or forgotten. Sharing information could prevent similar events from happening again.

- Leadership Commitment: No program can succeed without the backing of leadership. Leaders at all levels, from site managers to corporate executives, must champion process safety. This commitment must be reflected in company culture, investment in safety programs, and clear accountability structures. Strong leadership sets the tone for the entire organization, creating an environment where safety isn’t an afterthought but a fundamental part of operations.

The Path Forward

Without addressing these fundamental issues—better regulatory oversight, clear safety guidelines, improved skills and training, and leadership commitment—accidents like the ones we’ve witnessed will continue to dominate headlines for a few days, only to be forgotten until the next tragedy occurs.

We must move beyond this reactive cycle of shock, outrage, and inaction. The solution lies in proactive, collective ownership by all stakeholders, from regulatory bodies to industry leaders, workers, and technical experts. Process safety is everyone’s responsibility, and we must treat it as such—before more lives are lost. We must learn from other countries who were in similar situation decades ago, (Bhopal was 40 years ago so we never learnt lessons!). Following could be soultions.

Many countries with advanced industrial sectors have faced similar challenges with process safety but have made significant progress in preventing chemical accidents through strong regulatory frameworks, industry standards, and cultural changes. India can draw important lessons from their experiences and tailor these practices to fit its own context.

Lessons from Other Countries on Process Safety

Key Areas for India to Focus On:

- Stronger Regulatory Framework: India needs a more defined and enforceable version of process safety regulations like PSM (USA) and Seveso. (EU) There should be clear mandates on hazard identification, risk assessment, and engineering safety controls.

- Empowering and Training Regulators: Regulatory agencies are often understaffed and under-trained. To match the scale of the chemical industry, India should invest in building a competent and empowered regulatory body, similar to the HSE in the UK or the EPA in the U.S. This would involve increasing the workforce, equipping regulators with technical skills, and funding for safety inspections and audits.

- Mandatory Safety Reporting and Public Access: Companies must submit annual safety reports detailing the potential risks of their operations and the preventive measures in place, similar to the Safety Case Regime in the UK or the Seveso Directives in Europe. This data should be publicly accessible to create transparency and hold companies accountable.

- Stricter Penalties for Non-compliance: As I mentioned, penalties in India are often negligible. India can learn from the U.S. and Europe, where significant fines, shutdowns, and personal accountability (including imprisonment for negligence) act as real deterrents to safety violations.

- Industry-Led Safety Initiatives: Instead of relying solely on government enforcement, the chemical industry in India should be encouraged to form self-regulating organizations that promote safety best practices. Industry-led audits and cross-company safety benchmarking could help raise safety standards across the sector.

- Public Engagement and Transparency: Similar to the Seveso Directive, industries must engage the local community by offering transparency about potential risks and the measures they’re taking to mitigate them. Public trust can be built through open communication and community involvement.

- Building a Safety Culture: Leadership accountability, as seen in the UK and the U.S., should be emphasized in India. This means top executives and managers must be held responsible for safety failures. A culture of safety, from the CEO down to the shop floor, is critical to preventing accidents. We never heard a CEO resigning or fired by Board for so many lost lives in India.

How does China Fare?

China’s approach to industrial safety and accident prevention, while significantly more developed than India’s in terms of regulation and enforcement, has some stark similarities, particularly in the challenges it faces. Both countries are industrial powerhouses with complex hazardous chemical manufacturing sectors, but China has made notable strides in recent years to improve its process safety management, although it still grapples with frequent accidents, similar to India. Let’s break it down:

Regulatory Landscape: China vs. India

1. China’s Strengthened Regulatory Framework

China’s regulatory approach to industrial safety, especially hazardous chemical management, has seen improvement since the 2015 Tianjin explosions that killed 173 people and highlighted severe lapses in safety oversight. Since then, China has ramped up regulations and enforcement, although challenges remain.

- Work Safety Law and Regulations: China introduced stringent safety laws, including the Work Safety Law, which covers nearly every industry. For hazardous chemicals, the Regulation on the Safe Management of Hazardous Chemicals enforces strict standards for storage, transportation, and handling of chemicals, requiring comprehensive hazard identification and risk assessments.

- Safety Audits and Inspections: After high-profile incidents, China introduced stricter safety audits and inspections. For example, the State Administration of Work Safety (SAWS) conducts frequent safety audits, and unannounced inspections of chemical plants have become more common post-2015.

- Special Regulatory Zones: China has also started moving hazardous chemical plants to special industrial zones, far from urban areas, to reduce the impact of accidents.

However, while China has stricter regulations on paper compared to India, enforcement remains inconsistent, especially in rural and less developed areas where chemical plants may cut corners to save costs, similar to what happens in India.

India’s Regulatory Gaps: In contrast, India still struggles with a fragmented regulatory framework, weak enforcement, and poor safety audits. The lack of mandatory process safety management (PSM) systems across industries and underfunded regulatory agencies mean accidents are often dealt with reactively rather than proactively. Key Indian regulations, such as the Factories Act and the Environment (Protection) Act, are not always robustly applied, and penalties for non-compliance are too minor to deter negligent practices.

Comparison: China has made more concerted efforts post-Tianjin to tighten safety rules and increase inspections, while India’s regulatory enforcement remains largely ineffective, especially at regional levels. In practice, both countries face challenges with corruption, regulatory capture, and a lack of qualified safety inspectors, leading to gaps in actual on-ground enforcement.

2. Penalties and Accountability

- China’s Approach: Post-2015, China has shown more political will to penalize offenders, including arrests of company executives and local officials after major accidents. This approach aims to hold individuals accountable, especially when negligence is evident. Penalties include severe fines, plant shutdowns, and criminal charges against responsible parties.

- India’s Approach: In India, penalties are still relatively minor. Even after major accidents, criminal accountability is rare, with fines often being inconsequential compared to the scale of the damage caused. Regulatory agencies in India also face issues of corruption, understaffing, and limited training, leading to inconsistent enforcement.

Comparison: China is further ahead in imposing serious penalties and criminal accountability for major accidents, while India is still perceived as more lenient. This is a critical area where India could learn from China’s willingness to hold higher-ups responsible for safety lapses.

Cultural and Industrial Attitude Towards Safety

1. China’s Push for Industrial Safety Culture

- Leadership Commitment: In recent years, China has begun emphasizing the importance of building a safety culture within industries. Large companies, especially state-owned enterprises (SOEs), have been mandated to prioritize safety with top-down directives coming from the central government. Safety culture is increasingly being woven into the industrial operations of large firms, though it remains uneven in smaller, private firms.

- Use of Technology: China is increasingly relying on advanced technologies like real-time monitoring systems, drones, and AI for safety inspections and hazard detection. The government is encouraging the use of automation to minimize human error in hazardous processes.

India’s Struggles with Safety Culture: In India, building a strong safety culture is still a major challenge. Safety is often seen as an afterthought, and middle management often prioritizes production efficiency over process safety. Many plants, especially smaller ones, operate with outdated equipment, minimal safety protocols, and poor risk assessment practices.

Comparison: While China is actively pushing to improve its safety culture, India is still in the early stages. There is a stronger focus on compliance in China’s SOEs and larger corporations, whereas in India, safety awareness and cultural commitment remain inconsistent.

2. Training and Competence

- China’s Efforts: China has ramped up training for workers and managers in hazardous industries. The National Emergency Management Ministry was established to handle both safety training and emergency response, combining resources from various ministries. Large-scale simulation drills and mandatory safety training sessions are becoming more common in China, especially after 2015.

- India’s Challenges: In India, however, training programs are often either non-existent or underfunded. Workers in hazardous chemical industries frequently lack the knowledge to recognize and respond to potential hazards. With lower educational backgrounds and inadequate training systems, employees are ill-equipped to handle process safety, which leads to repeated accidents.

Comparison: China’s investment in safety training, especially in SOEs, is more structured compared to India’s, where training programs are often under-prioritized. India could benefit from China’s model of state-sponsored training and mandatory safety drills to improve worker competence in handling hazardous chemicals.

What India Can Learn from China:

- Stricter Enforcement and Accountability: China has shown greater political will to hold individuals accountable and impose heavier penalties. India could follow this by strengthening legal consequences for negligence and ensuring regulatory bodies are empowered to take swift action against violators.

- Investment in Training and Technology: India needs to invest in training programs for workers and managers, much like China’s efforts post-Tianjin. Additionally, the use of technology like real-time hazard monitoring and AI for predictive maintenance can reduce human error, a common cause of accidents.

- Creating Special Industrial Zones: China’s move to relocate hazardous industries to special zones is something India could replicate. It would not only reduce the risk of urban industrial accidents but also make regulation and enforcement easier within contained areas.

- Improving the Safety Culture: India must foster a stronger commitment to safety culture across industries, as China has begun to do. This includes instilling a questioning attitude, empowering middle management to champion safety, and ensuring leadership is directly accountable.

Conclusion: A Small Beginning, A Vital Step Forward

India has the potential to transform its approach to process safety in hazardous chemical manufacturing. If we truly put our heart and collective will into this mission, there’s no reason why we can’t turn the tide. It’s important to remember that no change, no matter how sweeping, begins overnight. However, the first step—a small but committed beginning—sets the course for a much-needed transformation.

Well begun is half done. Implementing stricter regulations, fostering a safety-first culture, and investing in technology and training could lead us to a future where preventable tragedies are no longer regular news headlines. Industry leaders, regulators, and workers must all join forces to make chemical safety a priority. We’ve seen examples from around the world—if China, after experiencing its own disasters, can make strides, then so can we.

The real question is—will we? Will India’s industries, its leaders, and its regulators embrace the opportunity to safeguard lives, or will we continue to react only after tragedy strikes? The choice is in our hands, and the time to act is now. India can do it, but it must be willing to begin. A small step today can pave the way for monumental change tomorrow.

Karthik

6th Sep 2024

12Noon.