#210

In the ever-evolving landscape of technology, one concept that has caught my attention recently is the “Digital Twin.” The idea that a physical entity—be it a flying airplane or even a human body—can have a virtual counterpart that mirrors its performance in real-time is nothing short of revolutionary. While this concept is already making waves in aviation and medicine, I believe it holds immense potential for the Environment, Health, and Safety (EHS) domain in the years to come.

What is a Digital Twin?

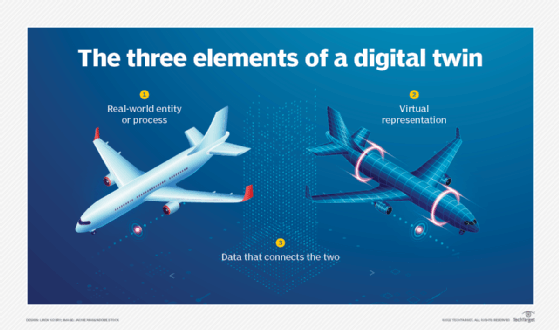

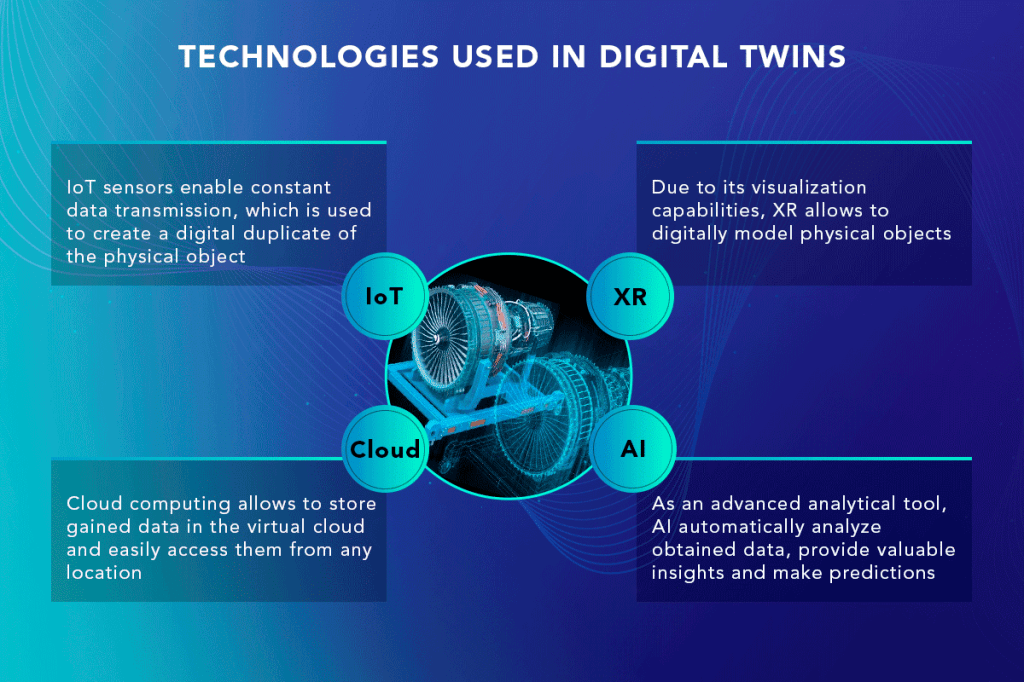

In simple terms, a Digital Twin is a real-time virtual representation of a physical object, system, or process. It collects data from sensors and uses this information to simulate, predict, and optimize performance. For instance, in aviation, Digital Twins of airplanes are created to monitor their performance during long-haul flights. These twins can predict issues related to engine wear, fuel efficiency, and even mechanical failures, allowing for proactive maintenance the moment the plane lands. This approach minimizes downtime and enhances safety by preventing problems before they occur.

How Digital Twins are Transforming Healthcare

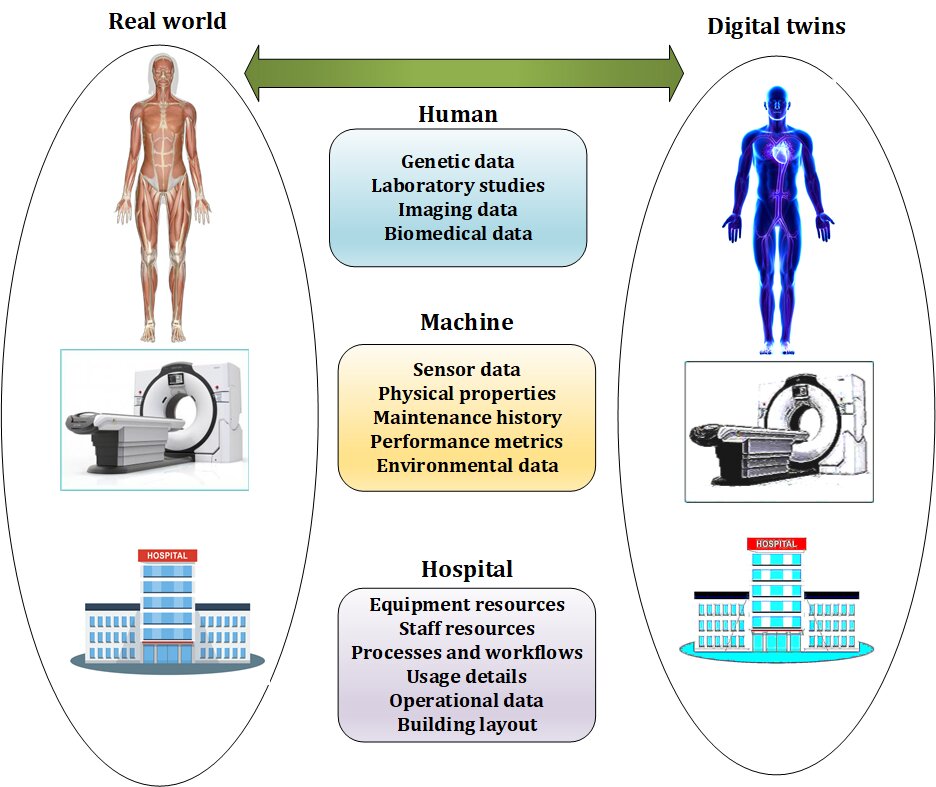

One area where the Digital Twin concept is rapidly gaining ground is healthcare. By creating virtual models of human organs or even entire systems, doctors can simulate treatment outcomes, predict the progression of diseases, and tailor personalized medical solutions. This capability could change the way healthcare professionals manage patient safety and medical interventions, reducing the risks involved in complex procedures.

Can the Digital Twin Revolutionize EHS?

This brings us to the critical question: How can Digital Twin technology be applied in the EHS domain? The possibilities are intriguing.

- Safety in Industrial Environments: Imagine creating a Digital Twin of a manufacturing plant where hazardous chemicals are handled. This twin could monitor real-time data on temperature, pressure, chemical reactions, and equipment wear, predicting potential safety hazards before they manifest. If there’s a risk of an explosion or gas leak, alerts could be generated, allowing preventive actions to be taken. It’s a proactive approach to managing safety risks, replacing the reactive methods traditionally employed.

- Environmental Monitoring: In environmental management, Digital Twins could model ecosystems, water systems, or air quality in and around industrial sites. Using real-time sensor data, organizations could predict environmental impacts before they occur, whether it’s contamination, emissions, or water waste. This technology could ensure compliance with regulatory standards and help companies take corrective action long before they violate environmental laws.

- Occupational Health: Digital Twins can also be applied to occupational health. By creating a digital replica of a worker’s environment and tasks, companies could simulate ergonomic risks, exposure to hazardous substances, or overexertion. Wearable sensors on employees could feed data into the system, allowing real-time adjustments to reduce fatigue, strain, or exposure levels.

- Emergency Response Preparedness: Digital Twins can simulate emergency scenarios such as chemical spills, fires, or natural disasters. These virtual models would help organizations test their emergency response plans in real-time, identifying weaknesses in evacuation routes, fire suppression systems, or first-aid readiness. This can vastly improve preparedness and reduce response times, ultimately saving lives.

Overcoming Challenges

As with any technological innovation, there are challenges to implementing Digital Twins in the EHS domain. High initial costs, data privacy concerns, and the need for continuous updates from real-world systems are a few hurdles that must be addressed. However, as technology advances and costs come down, the benefits will likely outweigh the drawbacks, especially when the stakes are as high as human lives and environmental sustainability.

Conclusion: The Digital Twin as a Game Changer

The EHS domain has always relied on reactive measures—corrective actions taken after an incident occurs. Digital Twin technology can shift the focus from reaction to prevention, allowing organizations to foresee risks and mitigate them in real time. While this may sound like science fiction today, I believe that in the not-too-distant future, (Even in my lifetime) Digital Twins will become a standard tool in EHS management, much like predictive analytics has transformed fields like aviation and healthcare.

It’s an exciting time to be in the EHS profession, and I, for one, can’t wait to see how this fascinating concept will revolutionize our field.

B Karthik

8th Sep 2024.

1400 Hrs.