#228

With US elections (2024) beginning in a couple of hours, I thought I can touch on the Compliance aspect of Safety/ Environment that exist there.

Frequent OSHA Citations in General and Construction Industries: Root Causes and Avoidance Strategies

Occupational Safety and Health Administration (OSHA) frequently issues citations in the general and construction sectors, especially in areas prone to high-risk activities. Some of the most common citations include fall protection, hazard communication, respiratory protection, lockout/tagout, and machine guarding. Despite being well-publicised, these remain constant areas of concern, leading to financial penalties, reputational risks, and, in some cases, even civil or criminal prosecution. So, why do these violations persist?

Why OSHA Citations Happen: Key Reasons

- Complexity of Compliance: US OSHA regulations can be complex, making it challenging for organisations to stay fully compliant, especially in large, multi-site operations.

- Resource Constraints: Smaller companies or those with tight operational budgets often compromise safety due to lack of resources. Compliance may take a backseat to production pressures, a common issue in construction.

- Insufficient Training: Without regular, updated training, employees might fail to understand and apply safety procedures correctly.

- Poor Safety Culture: A safety culture focused on “reactive” rather than “proactive” measures often results in overlooked hazards.

- Failure to Prioritise Safety: When leadership doesn’t prioritise safety, it trickles down through the workforce, leading to compliance failures.

Strategies to Avoid OSHA Citations

- Conduct Regular Audits and Assessments: Proactive internal audits help identify potential violations before they escalate. Regular safety assessments provide insights into improvement areas and prevent minor issues from becoming major citations.

- Invest in Training and Awareness: Comprehensive and frequent training is vital. From frontline employees to supervisors, everyone should be clear on OSHA requirements and the company’s safety protocols.

- Strengthen Safety Culture: Leadership must visibly prioritise safety. When safety is viewed as a core company value, rather than an obligation, employees feel empowered and motivated to uphold it.

- Establish Clear Documentation and Reporting Systems: OSHA citations often arise from poor documentation or non-compliance with reporting standards. A structured reporting system ensures that incidents and corrective actions are well-documented and accessible.

- Engage with EHS Professionals: Consulting with EHS specialists for guidance and compliance checks is essential, especially when setting up safety systems in complex industries.

Organisations that prioritise these steps often see better compliance rates, which can translate into fewer citations and a safer, more productive workforce.

The Untouched Aspect of EPA Compliance: A Tough Balancing Act

In addition to OSHA, many companies in the United States must also comply with environmental standards set by the Environmental Protection Agency (EPA). The EPA is tasked with enforcing environmental laws to protect public health and the environment, but its stringent policies often lead to companies viewing it with trepidation, even earning the label of “Compliance Terrorist.”

Understanding the EPA Compliance Program

The EPA monitors a wide range of environmental aspects, from air quality to hazardous waste management, and enforces policies that require companies to minimise their environmental impact. Key areas of EPA oversight include:

- Air and Water Quality: Regulations here mandate limits on emissions and effluents, particularly relevant to industries with high pollution levels.

- Waste Management: Companies must handle, store, and dispose of waste materials in compliance with federal and state laws.

- Chemical Handling and Spill Prevention: This includes stringent protocols for handling hazardous materials and preventing spills, especially in industries like manufacturing and petrochemicals.

- Climate Action and Resource Management: This is an evolving area where EPA mandates increasingly target emissions reductions and sustainable resource use.

The EPA maintains its compliance program through routine inspections, reporting requirements, and enforcement actions. The EPA is empowered to impose penalties on companies that violate these standards, and in severe cases, it can halt operations or mandate costly remedial actions.

Challenges Faced by Companies in EPA Compliance

- Stringent Standards and High Penalties: Compliance often involves significant investments in technology and processes, which can be costly for companies, especially for those with limited budgets.

- Frequent Updates and Complexity: EPA guidelines are regularly updated to reflect the latest environmental science, but these frequent updates can make compliance a moving target.

- Resource-Intensive Monitoring: Companies must establish environmental monitoring systems to ensure compliance, which requires skilled personnel, technology, and operational adjustments.

- Balancing Production with Compliance: Compliance requirements sometimes conflict with production targets, leading to difficult trade-offs, especially in competitive industries.

EPA Compliance: The Need for a Mindset Shift

To manage EPA compliance effectively, companies must view environmental stewardship not as a regulatory burden but as an integral part of responsible corporate governance. Here are some steps they can take:

- Adopt an Environmental Compliance Culture: Much like safety, environmental compliance should be integrated into company values and daily operations. This shifts the approach from compliance avoidance to genuine environmental responsibility.

- Implement Advanced Monitoring Technologies: Automated systems can track emissions, waste disposal, and other environmental parameters in real time, helping companies stay on top of compliance requirements.

- Engage in Industry Partnerships: Some industries work with environmental consultants or industry groups to create compliance benchmarks and best practices, making it easier to adapt to EPA guidelines.

- Transparent Reporting: Establishing transparent reporting practices can build trust with regulatory agencies and even reduce penalties in cases of accidental violations.

Beyond Compliance: Building Trust with Environmental Agencies

When companies take proactive steps toward EPA compliance, they often foster stronger relationships with regulatory bodies. A collaborative approach, rather than an adversarial one, can yield benefits in terms of compliance flexibility and brand reputation. While the EPA may be viewed with scepticism, companies that successfully integrate environmental responsibility into their operations often find that it brings long-term benefits, both operationally and ethically.

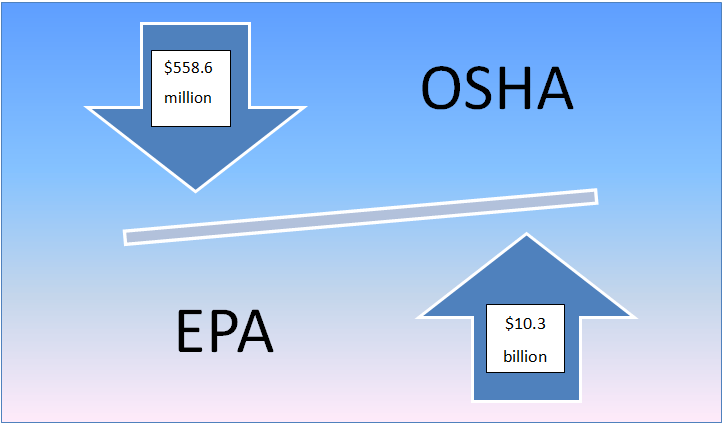

Understanding the financial implications of non-compliance with OSHA and EPA regulations is crucial for industries aiming to maintain safety and environmental standards.

Average Penalties Imposed by OSHA and EPA

- OSHA Penalties: In Fiscal Year (FY) 2022, OSHA conducted 31,820 inspections, resulting in numerous citations. The maximum penalties for violations as of January 2024 are:

- Serious, Other-Than-Serious, and Posting Requirements: $16,131 (Rs. 10 Lacs) per violation.Failure to Abate: $16,131 per day beyond the abatement date.Willful or Repeated: $161,323 (Rs. 1 Crore) per violation.

- EPA Penalties: In FY 2023, the EPA’s enforcement actions resulted in over $704 (Rs. 5800 Crores) million in penalties, fines, and restitution, marking a 57% increase over FY 2022. Environmental Protection Agency This substantial figure underscores the EPA’s rigorous enforcement of environmental regulations.

Major Areas Leading to Significant Penalties

- Safety Violations (OSHA):

- Fall Protection: Consistently the most cited violation, particularly in construction, leading to severe penalties. MSC Industrial Supply

- Hazard Communication: Failures in properly informing and training employees about hazardous materials result in significant fines.

- Respiratory Protection: Non-compliance in providing adequate respiratory protection equipment and training incurs substantial penalties.

- Environmental Violations (EPA):

- Clean Air Act (CAA) Violations: Industries such as oil, chemicals, and primary metals often face hefty fines for exceeding emission limits. For instance, the primary metal industry faced average penalties of $169,858. Mapistry

- Clean Water Act (CWA) Violations: Improper discharge of pollutants into water bodies leads to significant fines. Average settlements for CWA violations were approximately $68,472. RMA Green

- Resource Conservation and Recovery Act (RCRA) Violations: Mismanagement of hazardous waste results in substantial penalties.

Bottomline Impact:-

Non-compliance with OSHA and EPA regulations can lead to severe financial repercussions. Industries must prioritize adherence to safety and environmental standards to mitigate these risks. Regular audits, employee training, and a proactive compliance culture are essential strategies to avoid such penalties.

Judicial Powers and Enforcement: The High Stakes of Non-Compliance with OSHA and EPA

In the United States, non-compliance with OSHA and EPA standards goes beyond financial penalties—these agencies wield substantial legal authority to enforce regulations through judicial means. This is a major differentiator compared to many countries, where regulatory enforcement may be less stringent or penalties less severe. In the US, OSHA and EPA have both the legal framework and judicial support to enforce compliance through substantial penalties, civil action, and even criminal prosecution in cases of severe negligence or deliberate misconduct.

How OSHA and EPA Are Legally Empowered

- Legislative Authority: OSHA and EPA are governed by federal laws that grant them the authority to set regulations, conduct inspections, and issue citations. For OSHA, this power stems from the Occupational Safety and Health Act of 1970, which allows them to enforce workplace safety standards across industries. The EPA operates under various environmental laws, including the Clean Air Act, Clean Water Act, and the Resource Conservation and Recovery Act, which establish strict requirements for environmental protection.

- Judicial Backing: When companies fail to comply, both OSHA and EPA can pursue legal action in federal courts to enforce penalties. For serious violations, they can refer cases to the Department of Justice (DOJ) for criminal prosecution. In cases involving severe environmental harm or gross safety violations, executives and managers may even face criminal charges, resulting in significant fines and, in rare cases, imprisonment.

- Authority to Halt Operations: Both OSHA and EPA can issue cease-and-desist orders, requiring companies to stop specific operations until compliance is achieved. This authority underscores the high stakes of non-compliance, as a halt in operations can have severe financial consequences for businesses.

The High Cost of Non-Compliance

Non-compliance with OSHA and EPA regulations is costly for companies in multiple ways:

- Financial Penalties: As mentioned earlier, OSHA violations can lead to fines of up to $161,323 per violation in cases of repeated or willful non-compliance. EPA violations are even more costly, with multi-million dollar penalties not uncommon in industries like chemicals, oil, and heavy manufacturing. Additionally, EPA violations often include costs for environmental remediation, which can far exceed the initial fine.

- Legal Fees and Compliance Costs: Companies facing citations must often invest in extensive legal counsel and compliance measures to avoid additional penalties. These costs can run into millions of dollars, especially for complex environmental cases that require lengthy remediation processes.

- Restricted Eligibility for Government Contracts: In industries where companies bid for government contracts, OSHA and EPA violations can be particularly damaging. Criminal prosecutions or severe citations may render companies ineligible to submit tenders, effectively closing the door on lucrative government contracts. This restriction can significantly impact revenue streams for companies reliant on public sector contracts, as many institutions require a clean compliance record as a prerequisite for eligibility.

OSHA Penalties as Part of Operating Budgets

It is indeed true that, in certain industries, OSHA penalties have become an expected part of operating budgets. Companies operating in high-risk sectors, such as construction, oil and gas, and manufacturing, sometimes account for these penalties as “contingent liabilities.” However, it’s essential to note that this practice isn’t sustainable and reflects a risk-tolerant approach that regulators view unfavorably. Repeated citations can lead to heightened scrutiny, higher fines, and, in extreme cases, loss of operational permits or shutdown orders.

Criminal Prosecution as a Deterrent

When OSHA or EPA violations result in severe outcomes—such as worker fatalities, toxic spills, or environmental contamination—the agencies may pursue criminal charges to set a precedent. Cases where companies knowingly disregard safety or environmental standards carry severe reputational damage, besides the loss of market opportunities due to tender ineligibility for government contracts.

The Takeaway: The Long-Term Impacts of Compliance and Non-Compliance

Companies in high-risk industries must view OSHA and EPA compliance as a critical aspect of risk management. Beyond the immediate cost of fines, non-compliance can lead to long-term financial repercussions, including lost contracts, reputational damage, and restricted business growth. By integrating safety and environmental standards as part of core business practices, organisations can reduce regulatory risk and foster a culture that values both safety and environmental stewardship—ultimately protecting both their employees and the environment.

Concluding Thoughts

For EHS professionals and business leaders, compliance with OSHA and EPA regulations isn’t just about avoiding penalties—it’s about creating a safer, more sustainable workplace. OSHA compliance ensures the health and safety of workers, while EPA compliance contributes to environmental stewardship. Adopting a proactive stance on both fronts not only helps companies avoid costly legal battles but also positions them as responsible corporate citizens in a world where safety and environmental integrity are valued more than ever.

Karthik

5/11/24. 3pm.