#235

Introduction:

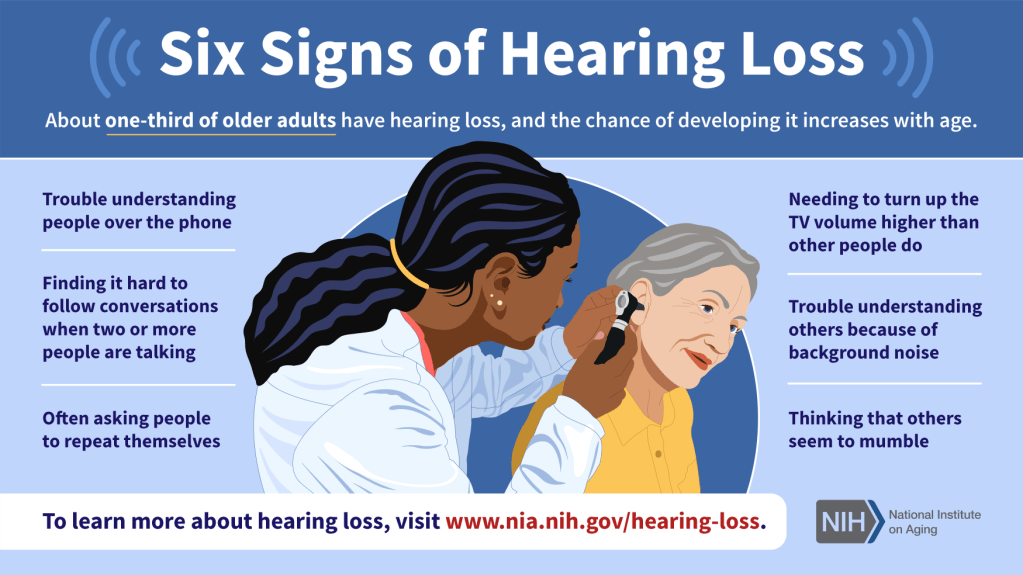

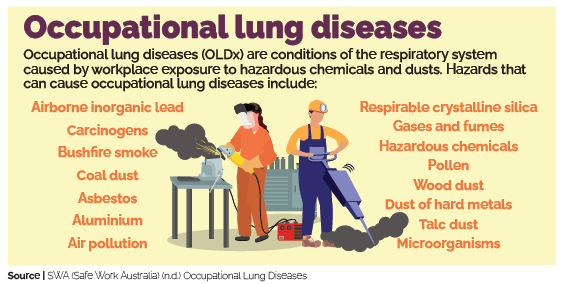

In the Indian manufacturing sector, safety programs like LOTO (Lockout/Tagout) and electrical safety often take precedence due to their immediate risk profiles. However, two chronic health issues—noise-induced hearing loss (NIHL) and respiratory illnesses caused by poor air quality—receive far less attention. Hearing protection programs and respiratory protection programs are grossly neglected, despite their potential for long-term, debilitating health impacts.

This blog highlights the need for a paradigm shift in recognising and addressing these hazards, offering practical insights for safety professionals to implement robust programs for hearing and respiratory protection.

1. Hearing Protection Program

Elements of a Comprehensive Hearing Protection Program:

- Noise Hazard Assessment:

- Conduct noise surveys using sound level meters to identify high-noise areas and tasks.

- Frequency-weighted measurements (e.g., dBA) should evaluate daily exposures against permissible limits.

- Regulatory Limits:

- India: The Factories Act, 1948 and Model Rules set noise exposure limits at 90 dBA over 8 hours, but enforcement is rare.

- Global Standards: OSHA sets limits at 85 dBA over 8 hours, while ACGIH recommends stricter thresholds.

- Engineering Controls:

- Use sound barriers, mufflers, vibration damping, or noise-cancelling machinery.

- Aim to reduce noise at the source before relying on personal protection.

- Administrative Controls:

- Job rotation and limiting time in high-noise areas can reduce individual exposure.

- Hearing Protection Devices (HPDs):

- Earplugs and earmuffs, selected based on Noise Reduction Ratings (NRR), must fit well and be comfortable for prolonged use.

- Training and Awareness:

- Educate employees on risks of NIHL and proper use, maintenance, and storage of HPDs.

- Audiometric Testing:

- Implement baseline and periodic audiometric tests to monitor workers’ hearing levels over time.

Challenges in Indian Manufacturing:

- Lack of Awareness: Many safety professionals are not trained to identify or address noise hazards adequately.

- Cultural Neglect: Chronic conditions like NIHL are often dismissed as “part of the job.”

- Cost Constraints: Engineering controls and audiometry programs are seen as expensive.

- Regulatory Gaps: Limited enforcement of noise standards and absence of penalties.

Solutions:

- Integrate Noise Management: Make noise hazard assessments part of annual safety audits.

- Leverage Technology: Use mobile apps and low-cost decibel meters for initial noise assessments.

- Advocate for Stronger Regulations: Push for mandatory implementation of global standards like ACGIH’s noise exposure limits.

- Cross-Sector Learning: Study industries with exemplary noise management practices, such as automotive and aerospace.

2. Respiratory Protection Program

Elements of a Comprehensive Respiratory Protection Program:

- Air Quality Monitoring:

- Conduct regular air sampling to identify contaminants such as dust, fumes, vapours, or gases.

- Use PM2.5/PM10 monitoring for particulate matter and gas detectors for specific hazards (e.g., silica, ammonia).

- Regulatory Framework:

- India: The Factories Act lacks detailed respiratory protection guidelines.

- Global Standards: OSHA requires respirators where contaminants exceed Permissible Exposure Limits (PELs).

- Respirator Selection:

- Match respirators to the specific hazard (e.g., N95 masks for particulates, SCBA for confined spaces).

- Ensure that all equipment is certified (e.g., ISI or NIOSH).

- Fit Testing:

- Perform qualitative or quantitative fit tests to ensure respirators provide an effective seal.

- Maintenance and Inspection:

- Train employees to inspect respirators for wear and replace filters regularly.

- Establish protocols for cleaning and storing equipment.

- Training and Awareness:

- Educate employees on the health risks of exposure to airborne contaminants.

- Demonstrate proper donning, doffing, and maintenance of respirators.

- Medical Evaluations:

- Workers required to wear respirators should undergo health checks to ensure fitness.

Challenges in Indian Manufacturing:

- Low Awareness of Chronic Risks: Respiratory hazards, like silica or welding fumes, Chemical exposure, are underestimated.

- Minimal Training: Workers often do not understand proper respirator use, leading to improper fit or non-compliance.

- Inferior Equipment: Cheap, non-certified masks are used instead of approved respirators.

- Lack of Data: Poor monitoring of air quality hinders hazard identification.

Solutions:

- Adopt ISO Standards: Align respiratory programs with ISO 45001 occupational health guidelines.

- Technology Investment: Use portable air quality monitoring devices to create exposure maps.

- Employer Accountability: Include respiratory protection metrics in key performance indicators (KPIs) for EHS leaders.

- Worker Engagement: Encourage worker participation in hazard identification and program development.

Best Practices for Both Programs

- Management Commitment:

- Secure leadership buy-in to treat chronic health risks with the same urgency as immediate hazards.

- Integrate with EHS Systems:

- Include hearing and respiratory protection in overarching EHS management systems (ISO 45001/14001).

- Customised Solutions:

- Tailor programs to specific industry needs, such as cement, steel, or textiles, where hazards vary.

- Leverage Data Analytics:

- Use wearable devices and IoT sensors to track real-time noise levels and air quality.

- Global Benchmarks:

- Study and adopt practices from developed countries where chronic hazard programs are mature.

- Awareness Campaigns:

- Celebrate initiatives like National Hearing Conservation Week or Clean Air Month to raise awareness.

Case Studies: Impact of Hearing Loss and Poor Respiratory Protection on Employees’ Lives

1. Hearing Loss Case Studies

Case Study 1: Persistent NIHL Among Factory Workers in India

- Industry: Textile Manufacturing

- Scenario: A group of power loom workers in Gujarat was exposed to noise levels exceeding 100 dBA for 10–12 hours daily. No hearing protection devices (HPDs) were provided, and noise-reducing measures like sound barriers were absent.

- Impact on Employees:

- Workers reported gradual hearing loss, starting with difficulty hearing conversations and progressing to complete hearing impairment in some cases.

- A study revealed that over 40% of workers had moderate-to-severe Noise-Induced Hearing Loss (NIHL) by age 50.

- Social isolation, frustration, and reduced quality of life were common consequences, leading to depression in some cases.

- Outcome:

- After a legal complaint by an NGO, the factory adopted engineering noise controls and distributed HPDs. However, the damage to workers’ hearing was irreversible.

Case Study 2: Construction Workers in the USA

- Industry: Construction (Roadworks)

- Scenario: Road construction workers were exposed to jackhammer noise exceeding 120 dBA over several years. Ear protection was provided but often neglected due to discomfort in hot weather.

- Impact on Employees:

- Several workers developed tinnitus (constant ringing in the ears), reducing their ability to concentrate.

- Many were forced into early retirement due to profound hearing loss, losing pension benefits tied to tenure.

- Outcome:

- A local safety campaign mandated custom-fit earplugs and training sessions on the importance of consistent use. Workplace noise levels were also monitored with IoT devices.

2. Respiratory Protection Case Studies

Case Study 1: Silicosis Epidemic in Indian Stone-Cutting Workers

- Industry: Stone Cutting and Polishing (Rajasthan)

- Scenario: Workers in small-scale stone-cutting units were exposed to silica dust from grinding stones without respiratory protection. Employers provided cloth masks, which were ineffective against fine particulate matter.

- Impact on Employees:

- Many workers developed silicosis—a chronic, incurable lung disease caused by silica inhalation—by their 30s.

- Symptoms included shortness of breath, fatigue, and chronic coughing. Several workers succumbed to the disease within a decade of diagnosis.

- Families faced severe financial hardship due to loss of income and medical expenses.

- Outcome:

- Following advocacy by health organisations, some units installed wet cutting systems and provided N95 respirators. Government intervention led to compensation schemes for affected workers, but enforcement remains weak.

Case Study 2: Chemical Plant Workers in China

- Industry: Chemical Manufacturing

- Scenario: Workers in a paint manufacturing plant were exposed to volatile organic compounds (VOCs) and isocyanates without adequate ventilation or respiratory protection. Many relied on disposable masks, which offered no protection against toxic fumes.

- Impact on Employees:

- A significant number developed occupational asthma, leading to frequent absenteeism and reduced work capacity.

- Some employees experienced acute respiratory failure and required hospitalisation. Long-term exposure led to a spike in cases of chronic obstructive pulmonary disease (COPD).

- Outcome:

- After an external audit highlighted the violations, the plant implemented a comprehensive respiratory protection program, including powered air-purifying respirators (PAPRs) and improved ventilation systems. Workers were retrained, but the health damage for affected employees was permanent.

3. Combined Impact of Hearing and Respiratory Hazards

Case Study: Shipbuilding Workers in South Korea

- Industry: Shipbuilding

- Scenario: Workers were exposed to high noise levels from welding and cutting operations while also inhaling welding fumes containing heavy metals and particulates. Personal protective equipment (PPE) compliance was low, and workplace monitoring was irregular.

- Impact on Employees:

- Many workers suffered combined effects of hearing loss and respiratory diseases, including COPD and lung cancer.

- Workers struggled with communication barriers due to hearing loss, complicating emergency situations in confined spaces.

- Outcome:

- The company invested in advanced PPE, including noise-cancelling earmuffs and respirators designed for welding fumes. Policies were updated to mandate regular health checks, but litigation from affected employees continues.

Key Learnings from These Cases

- Early Detection is Crucial: Regular monitoring of noise levels and air quality could have prevented many chronic conditions.

- Proper PPE Selection: Generic or low-quality PPE can be as dangerous as no protection. Fit testing and suitability checks are essential.

- Worker Training: Many of these cases highlight a lack of awareness among workers about the hazards they face and the proper use of protective equipment.

- Regulatory Oversight: Weak enforcement of safety standards exacerbates workplace hazards, especially in developing countries.

- Long-Term Costs: Health issues lead to productivity losses, increased medical expenses, and compensation claims, costing organisations far more than prevention programs.

These case studies underscore the urgent need for prioritising hearing and respiratory protection in manufacturing industries. Employers must act proactively to prevent irreversible health damage to their workforce and align with global safety standards.

Conclusion

Hearing loss and respiratory illnesses may not grab headlines like industrial accidents, but their impact is equally devastating. For Indian manufacturing to achieve world-class safety standards, addressing these chronic hazards is not optional—it is essential. Companies must move beyond regulatory compliance and adopt proactive, best-in-class strategies to protect their workforce.

The journey begins with awareness, commitment, and action. Let us not wait until the damage is irreversible.

Karthik

23/11/24 11am.