#277

In organizations where maturity levels in safety, quality, and operational excellence hover at low to average, the dream of cultural transformation can feel like chasing a mirage. Legacy mindsets of “we’ve always done it this way” dominate, and daily operational fires—mundane, repetitive, and often non-value-adding—consume the time and energy of employees and leaders alike. The desire for change is there, but the reality of implementing it? That’s where things get messy. Leaders, even those with control, often find themselves overwhelmed, and well-intentioned initiatives stall or collapse. So, how do we bridge this gap and make cultural change stick in such environments? Let’s dive into practical, actionable strategies to turn vision into reality while navigating the tightrope of daily operations.

The Challenge: A Tug-of-War Between Vision and Reality

In many organizations, the appetite for cultural change in Environment, Health, and Safety (EHS) is genuine. Leaders and teams recognize the need for safer workplaces, higher quality standards, and better employee engagement. But the weight of legacy practices, coupled with the relentless demands of daily operations, creates a perfect storm. Routine tasks, firefighting, and entrenched behaviors drown out progress. Even in unionized or resistant work environments, where shopfloor workers may feel disconnected from leadership’s vision, change initiatives struggle to gain traction. The result? Frustration, burnout, and a return to the status quo.

The good news? It’s not impossible to break this cycle. By combining strategic planning, incremental wins, and a blend of soft and hard power, organizations can achieve lasting cultural transformation. Below are eight practical strategies, building on your insights, to make it happen.

1. Anchor Change in a Clear Vision and Actionable Plans

A cultural shift without a clear vision is like a ship without a compass. Leaders must articulate a compelling why—why safety, quality, or behavioral change matters to the organization, its people, and its future. This vision should be backed by a mission statement and a commitment to focused, deliverable plans. “Action without plans is a trainwreck; plans without action is insanity.”

- How to do it: Develop a concise EHS vision (e.g., “Zero Fatality, thriving teams, sustainable operations”). Translate it into SMART goals (Specific, Measurable, Achievable, Relevant, Time-bound). Create a roadmap with short-, medium-, and long-term milestones. For example, reduce incident rates by 10% in six months or train 100% of supervisors on safety leadership within a quarter.

- Pitfall to avoid: Vague or overly ambitious plans that lack buy-in. Engage frontline workers and middle managers early to ensure the vision resonates.

2. Start Small, Win Big, Scale Up

In organizations with low maturity, aiming for a complete overhaul can be paralyzing. Instead, focus on small, high-impact areas where success is achievable. A single win builds momentum and credibility for broader change.

- How to do it: Identify a pilot project, like improving lockout-tagout compliance in one department or streamlining a quality check process. Ensure resources, training, and leadership support are in place. Once successful, celebrate the win and replicate it in other areas.

- Example: A manufacturing plant reduced near-miss incidents by 20% in one unit by standardizing toolbox talks. They then scaled the approach plant-wide, achieving a 15% overall reduction in incidents within a year.

3. Empower a Task Force with Clear Accountability

Cultural change needs champions. Form a cross-functional task force with representatives from leadership, middle management, and the shopfloor. Equip them with clear empowerment, tools, and accountability to drive change.

- How to do it: Set time-bound goals—weekly, monthly, quarterly, and half-yearly. For instance, “Implement a new safety observation program in one month” or “Reduce rework by 5% in three months.” Hold regular reviews to track progress, celebrate wins, and course-correct. Use dashboards or simple trackers to visualize results.

- Pro tip: Include a union representative or shopfloor leader to bridge the gap between management and workers, especially in resistant environments.

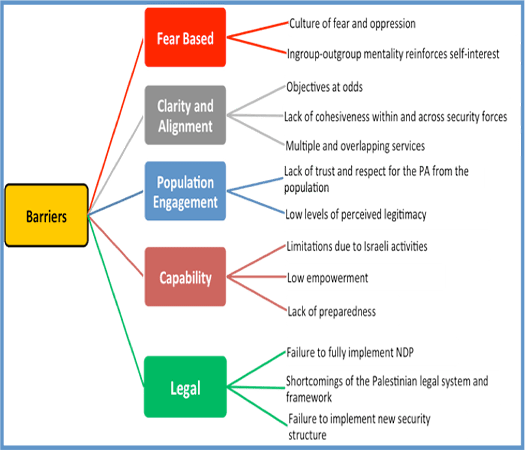

4. Identify and Tackle Barriers Head-On

Every change initiative faces roadblocks—whether it’s outdated processes, resistant behaviors, or lack of metrics to track progress. Proactively identify these barriers and address them with targeted corrective actions.

- How to do it: Conduct a barrier analysis early in the process. Ask: What’s stopping us? Is it lack of training, unclear procedures, or poor communication? For example, if workers bypass safety protocols due to time pressure, revise procedures to balance efficiency and safety. If progress metrics are missing, implement leading indicators like safety audits completed or training hours logged.

- Pitfall to avoid: Ignoring people-related barriers. Resistance often stems from fear of change or lack of clarity. Address these through open dialogue and training.

5. Free Up Change Agents by Delegating Routine Work

Daily operational demands can suffocate change initiatives. To succeed, key players need bandwidth to focus on transformation. This means delegating routine tasks to their teams, which also fosters growth and career development for others.

- How to do it: Train supervisors to delegate effectively, empowering their teams to handle daily tasks like shift reports or minor troubleshooting. This frees up leaders to focus on strategic initiatives like safety culture workshops or process redesign. Provide coaching to ensure delegation is done thoughtfully, avoiding overburdening teams.

- Bonus: Delegation builds trust and creates opportunities for junior employees to step up, aligning with career progression goals.

6. Blend Soft and Hard Power to Drive Change

In 2025, with rapid technological, regulatory, and societal shifts, organizations can’t afford to resist change. Driving cultural transformation requires a mix of soft power (inspiration, collaboration, empathy) and hard power (mandates, accountability, consequences). In hostile or unionized environments, candid communication is critical.

- How to do it: Use soft power to inspire—share stories of how safety improvements saved lives or how quality enhancements boosted customer trust. Use hard power to enforce accountability—set non-negotiable standards, like mandatory PPE compliance, with clear consequences for violations. In union settings, hold honest, two-way dialogues. Invite shopfloor input on how to implement changes, making workers partners in the journey.

- Example: A refinery facing union pushback on a new safety protocol held town halls where workers voiced concerns. Leaders addressed them by adjusting the protocol and providing extra training, turning skeptics into advocates.

7. Underpromise, Overdeliver, and Build Trust

Great organizations don’t overpromise and underdeliver. They set realistic expectations, take the time to get it right, and exceed goals. “It’s better to take a few extra days to deliver outstanding results than to make haste and waste.”

- How to do it: When launching a change initiative, communicate conservative timelines and outcomes. For example, promise a 5% reduction in incidents but aim for 10%. Use the extra time to refine processes and ensure quality. This builds trust and credibility, especially in skeptical workforces.

- Pitfall to avoid: Rushing to meet arbitrary deadlines. Quality trumps speed in cultural change.

8. Celebrate Success and Spread the Wins

Nothing fuels momentum like recognition. Celebrating successes, no matter how small, reinforces the value of change and motivates teams to keep going. Extending these wins to other areas amplifies impact.

- How to do it: Acknowledge achievements publicly—through newsletters, team meetings, or recognition boards. For example, highlight a team that reduced downtime by improving a safety process. Share lessons learned and apply them to other departments. Host quarterly “EHS Champions” events to showcase progress.

- Pro tip: Tie celebrations to tangible outcomes, like fewer incidents or higher employee engagement scores, to keep the focus on results.

Additional Practical Strategies

To round out the approach, consider these additional tactics:

9. Leverage Technology for Efficiency and Engagement

In 2025, digital tools can streamline EHS processes and engage employees. Use mobile apps for safety reporting, e-learning platforms for training, or data analytics to track leading indicators. Technology reduces the burden of manual tasks, freeing up time for cultural initiatives.

- Example: A construction firm implemented a mobile app for real-time hazard reporting, increasing worker participation by 30% and cutting incident response time in half.

10. Build a Learning Culture

Low-maturity organizations often lack a habit of continuous improvement. Foster a learning culture by encouraging feedback, conducting post-mortems on failures, and sharing best practices. This mindset shift supports long-term cultural change.

- How to do it: Hold “lessons learned” sessions after major projects or incidents. Encourage workers to suggest improvements without fear of blame. Reward innovative ideas with recognition or small incentives.

11. Align Change with Business Goals

To sustain leadership support, tie EHS cultural change to business outcomes like cost savings, productivity, or customer satisfaction. This ensures change initiatives aren’t seen as “nice-to-haves” but as critical to survival.

- Example: A factory linked its safety program to reduced insurance premiums, saving $50,000 annually. This secured executive buy-in for further investments in EHS.

Conclusion: Turning Dreams into Reality

Achieving cultural change in EHS while managing daily operational challenges is like walking a tightrope—it requires balance, focus, and resilience. By anchoring change in a clear vision, starting small, empowering teams, and blending soft and hard power, organizations can overcome legacy mindsets and low maturity levels. Celebrate wins, leverage technology, and align with business goals to sustain momentum. In 2025, with change happening at breakneck speed, organizations that adapt will thrive, while those that cling to “the way things have always been” risk being left behind.

The shopfloor is where change comes to life. Engage your people, listen to their insights, and make them partners in the journey. With the right strategies, even the most daunting cultural transformation is within reach. Let’s make safety, quality, and excellence not just goals, but the way we work.

Call to Action: What’s one small step your organization can take today to kickstart an EHS cultural change? Share your thoughts or success stories in the comments below!

Thanks

Karthik

9th June 2025 1230pm.