#241

My Final blog post of 2024. I am taking a break to spend quality time with son, daughter with their spouse, will be arriving for a month long vaccation from USA, this week. I will be back to blogging after 10th January 2025. I wish every one a Happy Prosperous and prodcutive -New Year 2025. 2024 was a great year for me, I am greatful. God bless.

Introduction

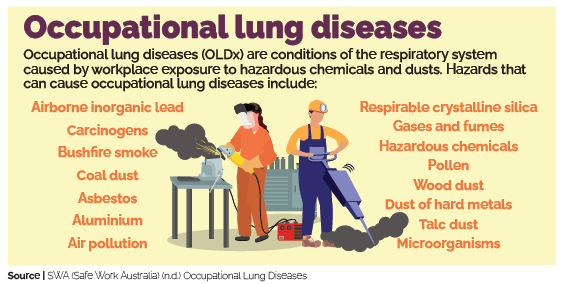

The evolution of Environmental, Health, and Safety (EHS) performance in manufacturing has been shaped by diverse regulatory, economic, and cultural factors. From the stringent frameworks of the EU and USA to India’s developing landscape, EHS practices reveal a mixed bag of successes, missed opportunities, and cautionary tales. As we approach 2025, uncertainties stemming from geopolitical tensions, economic slowdowns, and leadership changes demand a critical evaluation of past performance to chart a resilient future.

What Went Well

1. EU’s Progressive Regulations and Sustainability Focus

The EU maintained its leadership in EHS, driven by stringent regulations enforcement like the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) framework and the Green Deal. Initiatives such as circular economy adoption, net-zero emissions goals, and worker safety directives have created a culture of compliance and innovation.

- Example: Germany’s integration of Industry 4.0 with EHS initiatives has enhanced predictive maintenance, reducing workplace accidents and emissions.

- Key Insight: Strong enforcement, combined with incentives for green manufacturing, ensures sustained progress.

2. USA’s Balanced Approach and Technological Edge

The USA balanced regulatory demands with technological innovations. OSHA’s initiatives, combined with industry collaborations, have reduced fatality rates despite challenges like workforce shortages and supply chain pressures. AI-driven predictive analytics and IoT devices in manufacturing have enhanced hazard detection and reporting systems.

- Example: DuPont and 3M have set benchmarks in chemical safety and employee engagement.

- Key Insight: Integrating technology with existing EHS frameworks accelerates progress.

3. India’s Growing Awareness and Adaptation

In India, EHS awareness has significantly improved over the past decade. Campaigns like “Make in India” have brought focus to occupational safety and environmental sustainability. The adaptation of global standards (e.g., ISO 45001) by multinationals operating in India has raised the bar for domestic industries.

- Example: The pharmaceutical and automotive sectors in Pune and Bangalore are adopting international EHS practices.

- Key Insight: Building a compliance culture will be key to overcoming legacy challenges.

What Could Have Been Better

1. EU’s Bureaucratic Overreach

While the EU’s regulations are robust, compliance costs have burdened SMEs. The pace of legislative change often outstrips the ability of smaller firms to adapt, creating a compliance gap.

- Impact: Small manufacturers are reluctant to innovate due to high operational costs.

- Opportunity: Streamlining regulatory processes and providing subsidies can ensure inclusivity.

2. USA’s State-Level Variability

The decentralised regulatory framework in the USA has led to disparities in EHS enforcement. States with weaker governance lag in compliance, creating inconsistencies that impact national performance.

- Impact: Gaps in reporting and enforcement, especially in non-unionised sectors.

- Opportunity: Federal oversight and standardised training programs can bridge these gaps.

3. India’s Implementation Deficits

Despite better awareness, India continues to struggle with enforcement. Labour-intensive industries like textiles and construction frequently bypass safety norms due to cost and resource constraints.

- Impact: High fatality and injury rates persist, damaging global competitiveness.

- Opportunity: Strengthening audits, increasing penalties, and fostering worker education can improve compliance.

What Were the Disasters?

1. EU’s Energy Crisis and EHS Trade-Offs

The Ukraine war exposed Europe’s reliance on fossil fuels, (Russian Gas) causing energy shortages. Temporary rollbacks of environmental commitments—such as reopening coal plants—undermined EHS goals.

2. USA’s Manufacturing Accidents

Despite advanced systems, incidents like chemical spills and refinery fires in 2023 highlighted the limitations of current frameworks. Delayed maintenance and inadequate emergency planning were key culprits.

- Example: A major incident at a Louisiana chemical plant resulted in fatalities and environmental damage.

3. India’s High-Profile Failures

India’s Bhiwandi fire and Vizag gas leak are stark reminders of the consequences of neglecting safety systems. These incidents eroded public trust and invited global criticism.

Future Outlook: EHS in 2025

1. Trump’s Policies and U.S. Manufacturing

When Donald Trump resumes office, a pro-business stance could prioritise deregulation, potentially impacting EHS enforcement. However, his focus on energy independence may bring innovations in clean energy manufacturing.

2. War and Geopolitical Tensions

The ongoing Ukraine war and potential conflicts in Asia will strain global supply chains. Manufacturers will need to adapt by reshoring operations and increasing resilience against disruptions, emphasising workforce safety and environmental sustainability.

3. Economic Slowdowns and Cost Pressures

Economic challenges may force manufacturers to cut corners, affecting EHS investments. Conversely, these pressures could accelerate technological adoption, such as AI-powered EHS solutions, to reduce costs while enhancing safety.

4. India’s EHS Leap

India’s focus on becoming a manufacturing hub under global scrutiny will push reforms. Increased foreign investments in green technologies and stricter compliance frameworks could transform the EHS landscape.

The Trump administration’s approach to the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) has been characterized by a shift towards deregulation and a focus on industry collaboration.

Occupational Safety and Health Administration (OSHA):

- Leadership Appointment: Heather MacDougall, a former Amazon executive, is under consideration to lead OSHA. Her background suggests a potential emphasis on aligning regulatory practices with business interests.

- Policy Direction: The administration is expected to pivot from an enforcement-centric approach to one that fosters cooperation with the business community. This includes prioritizing compliance assistance programs and expanding initiatives like the Voluntary Protection Programs.

- Resource Allocation: Historically, the number of OSHA inspectors decreased during the previous Trump administration, leading to fewer inspections. A similar trend may continue, potentially resulting in reduced enforcement activity.

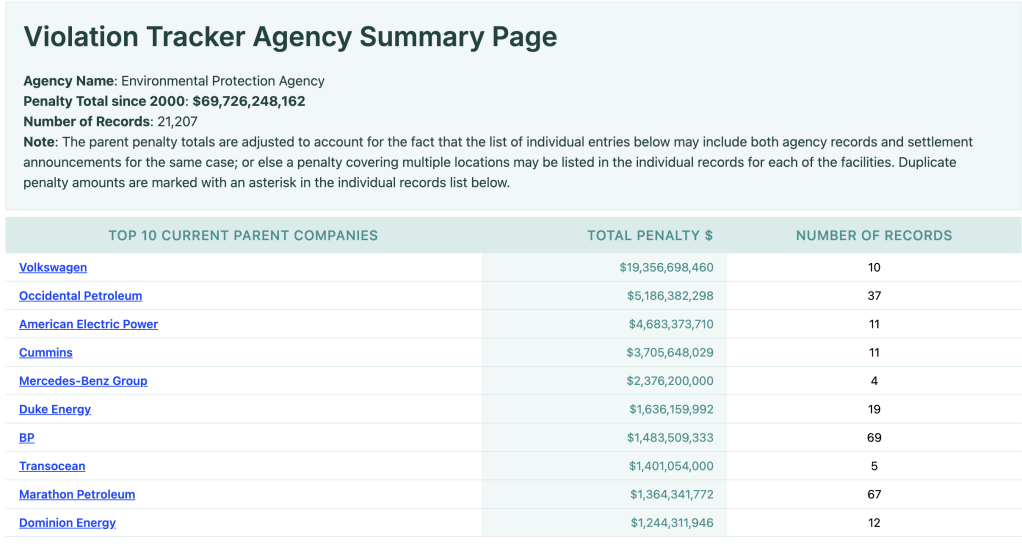

Environmental Protection Agency (EPA):

- Leadership Appointment: Former Rep. Lee Zeldin has been nominated to lead the EPA. His selection indicates a commitment to swift deregulatory actions aimed at stimulating economic growth while maintaining environmental standards.

- Regulatory Approach: The administration plans to continue or expand deregulatory policies from its first term, including rolling back regulations related to climate change and environmental protection. This may involve reducing the EPA’s budget and staff, thereby limiting its capacity for enforcement and scientific research.

- State Authority: There is an anticipated shift towards granting states more control over environmental standards, potentially leading to varied enforcement across the country.

The Trump administration’s appointments and policy directions for OSHA and the EPA suggest a continued focus on deregulation, increased collaboration with industry, and a decentralization of authority to states. These changes are expected to impact the enforcement and development of health, safety, and environmental regulations.

Conclusion

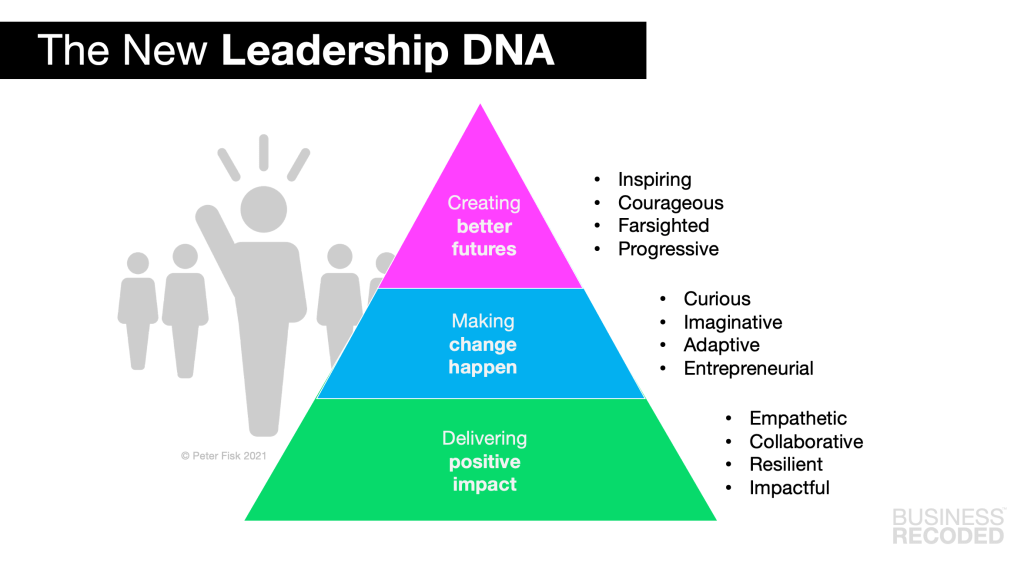

The journey of EHS performance in manufacturing underscores a blend of successes, challenges, and opportunities. As 2025 looms, the focus must shift to resilience, adaptability, and innovation. For the EU, USA, and India, collaboration and shared learning can create a robust EHS culture that aligns safety, sustainability, and profitability.

Karthik

14th Dec 2024 930am.