#232

Context: I read an interesting article on 41 Skills that need AI mesh up to enhance skills. That made me thinking.

The world is rapidly shifting towards digitisation, and artificial intelligence (AI) is no longer the distant future—it’s here and evolving daily. As professionals in the Environment, Health, and Safety (EHS) domain, we must actively embrace these advancements, not only to enhance workplace safety and compliance but also for personal growth and skills development. However, many organisations and individuals still sideline these transformative tools, limiting their potential to reshape EHS practices. It’s time to explore how embracing digitisation and AI can revolutionise EHS performance management and drive personal and professional development.

The Current Landscape of EHS

Traditionally, EHS management has relied on manual processes, spreadsheets, and fragmented reporting systems. While these approaches have served their purpose, they are riddled with inefficiencies, human error, and reactive decision-making. This conventional framework is inadequate for the modern workplace, which demands agility, accuracy, and foresight.

In today’s interconnected world, hazards are more complex, regulations are more stringent, and organisations are under constant pressure to ensure compliance while optimising performance. Digitisation and AI offer a pathway to achieve these objectives more effectively.

Leveraging Digitisation in EHS

Digitisation simplifies data collection, analysis, and reporting—cornerstones of effective EHS management. Some key benefits include:

- Real-Time Data Monitoring: Sensors and IoT devices can monitor workplace conditions (e.g., air quality, temperature, noise) in real time, enabling proactive responses to potential hazards.

- Centralised Systems: Cloud-based platforms consolidate data from various locations and functions, providing a unified view of safety performance.

- Streamlined Compliance Management: Digital tools automate documentation and regulatory compliance tracking, reducing the burden of manual updates and audits.

- Incident Management: Apps and dashboards allow instant reporting and tracking of near misses, incidents, and corrective actions, ensuring timely resolution.

AI: Transforming EHS Beyond the Basics

AI enhances the power of digitisation by enabling predictive analytics, risk assessment, and decision-making support. Here’s how:

- Predictive Analytics for Risk Prevention: AI algorithms can analyse historical data to predict potential risks or hazards, allowing organisations to take preventive actions before incidents occur.

- Personalised Safety Training: AI-driven tools can tailor training programs to individual needs, improving knowledge retention and engagement.

- Enhanced Audits and Inspections: AI-powered drones and image recognition software can conduct thorough site inspections, identifying hazards that might be missed during manual inspections.

- Worker Fatigue and Behaviour Analysis: Wearables with AI can track worker fatigue levels or detect unsafe behaviours, providing real-time feedback and corrective measures.

Personal Development Through AI and Digitisation

Digitisation and AI aren’t just about organisational performance—they’re equally vital for personal growth in EHS roles:

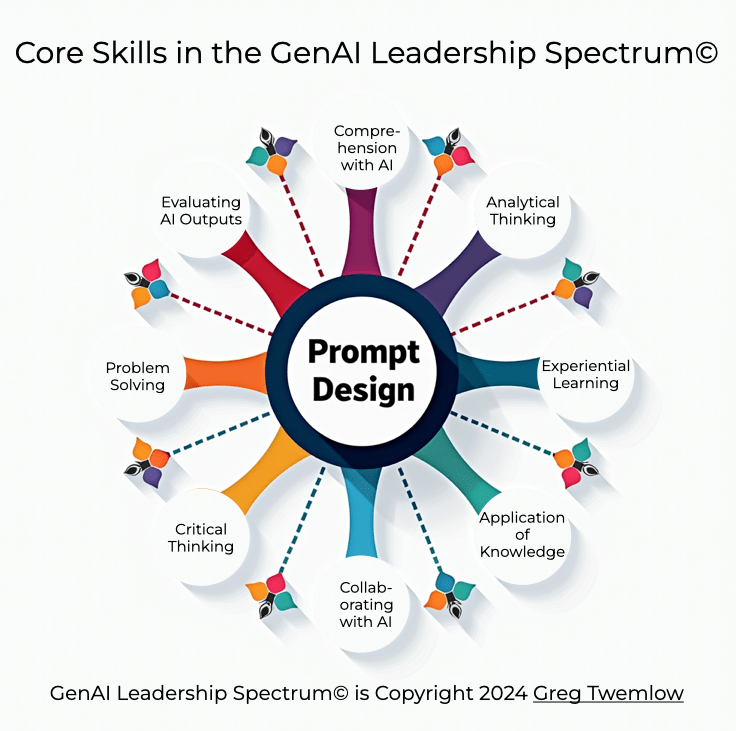

- Skill Development: Online platforms powered by AI recommend courses, certifications, and learning resources tailored to individual career paths.

- Efficiency and Productivity: Automating repetitive tasks allows EHS professionals to focus on strategic, value-added activities, fostering creativity and problem-solving.

- Decision-Making Confidence: Data-backed insights from AI enhance decision-making, empowering professionals to handle complex challenges with greater assurance.

- Networking and Collaboration: Digital tools facilitate global collaboration, exposing individuals to diverse perspectives and best practices.

Areas Requiring AI and Digitisation in EHS

The integration of AI and digitisation into EHS can significantly enhance various processes that traditionally relied on manual intervention and subjective judgement. Here are key areas where these technologies can drive transformational change:

- Accident Investigation – Sharpening the Saw: AI-powered tools can enhance root cause analysis by identifying patterns in data that might otherwise be overlooked. By using machine learning algorithms, organisations can uncover systemic issues, enabling preventive measures and more effective corrective actions.

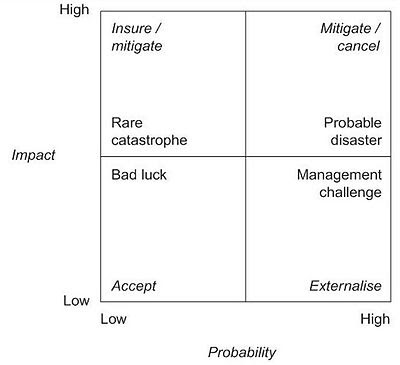

- Risk Assessment with Focus on Hidden Risks: Risk assessments often miss latent risks due to human biases or incomplete data. AI can analyse large datasets to identify hidden vulnerabilities and recommend targeted mitigation strategies, making risk assessments more robust and dynamic.

- Practical Training Modules: Virtual Reality (VR) and Augmented Reality (AR) technologies can simulate real-life scenarios, offering hands-on training in a controlled environment. AI customises training based on individual progress, ensuring a comprehensive learning experience.

- Corrective Action Planner, Tracker, and Closure: Digitised systems automate the planning, tracking, and closure of corrective actions. AI prioritises actions based on risk severity and ensures timely follow-ups, improving accountability and effectiveness.

- Legal Requirements Tracking – Corporate and Country: AI-powered platforms monitor regulatory updates in real-time, ensuring compliance with corporate and country-specific legal requirements. Automated alerts and documentation workflows simplify adherence to dynamic regulations.

- Industrial Hygiene (IH) and Medical Validations: Digitisation streamlines the tracking of workplace exposures and employee health data. AI identifies trends and flags potential health risks, ensuring early interventions and compliance with occupational health standards.

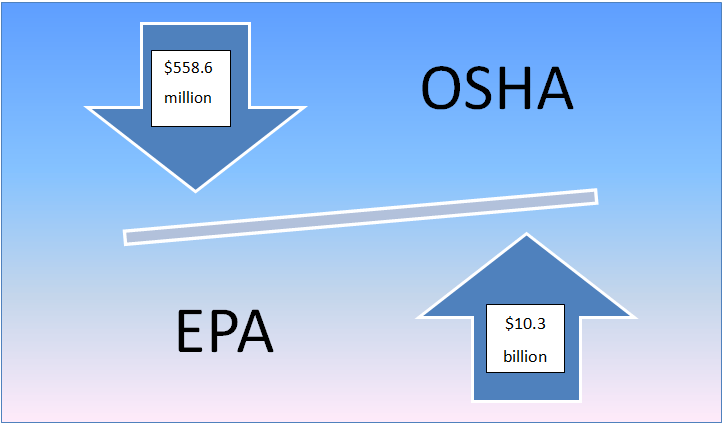

- Environmental Compliance – Air, Water, and Solid Waste: Automated systems monitor environmental parameters, integrate compliance data, and generate reports aligned with legal standards. AI can predict potential violations, enabling proactive corrective measures.

- Contractor EHS Management: AI tools assess contractor safety performance, monitor compliance, and flag deviations in real time. This ensures contractors adhere to organisational safety standards and regulatory requirements.

- Systems Audit: AI-driven audit systems enhance the accuracy and efficiency of internal and external EHS audits. They highlight non-conformities and provide actionable recommendations, ensuring continuous improvement.

Skill Development for Subject Knowledge and Personal Growth

The rapid digitisation of EHS processes necessitates a parallel development of skills to maximise the potential of these tools. Skill development should focus on two key areas: subject knowledge and personal competencies.

- Subject Knowledge:

- Technical Proficiency: Mastery of AI and digital tools specific to EHS, such as risk assessment software, data analytics platforms, and compliance management systems.

- Data Analysis: The ability to interpret and leverage data insights to make informed decisions, improve processes, and predict risks.

- Regulatory Knowledge: Staying updated on the latest EHS standards, regulations, and technologies to ensure compliance and drive innovation.

- Personal Competencies:

- Communication Skills: Clear, concise communication of safety protocols, incident reports, and data insights to stakeholders across all levels.

- Emotional Intelligence: Managing relationships, understanding team dynamics, and fostering a safety-first culture through empathy and leadership.

- Adaptability: Embracing technological changes with a growth mindset and a willingness to learn continuously.

By combining these technical and personal skills, EHS professionals can position themselves as forward-thinking leaders who drive not only compliance but also innovation and cultural transformation in safety and sustainability.

The Risks of Ignoring Digitisation and AI

Failing to embrace these tools can leave organisations and professionals lagging behind. Key risks include:

- Missed Opportunities for Risk Reduction: Without predictive insights, hazards may go unnoticed until it’s too late.

- Increased Workload: Manual processes are time-consuming, increasing burnout and reducing overall efficiency.

- Limited Career Growth: Professionals who don’t adapt to digital tools may struggle to remain relevant in an increasingly tech-driven field.

Steps to Embrace Digitisation and AI

- Start Small: Begin with simple tools like incident reporting apps or digital checklists, then gradually introduce more advanced solutions.

- Invest in Training: Equip your team with the skills needed to leverage digital tools effectively, including data analysis and AI literacy.

- Collaborate with IT Teams: Work closely with your organisation’s IT department to identify and implement suitable EHS technologies.

- Adopt a Growth Mindset: Stay curious and open to learning new technologies. Continuous self-improvement is key to thriving in a digitised environment.

The Future of EHS is Digital

The integration of digitisation and AI in EHS is not a question of if but when. Organisations and individuals that proactively adopt these tools will be better positioned to create safer, more efficient workplaces while driving personal and professional growth.

In a world where change is the only constant, adaptability is our greatest asset. Let us embrace digitisation and AI not as threats but as opportunities to transform EHS performance management and elevate ourselves as leaders in the field. After all, the future of safety lies in leveraging technology to predict, prevent, and perform.

What’s your perspective on digitisation and AI in EHS? Have you started your journey yet? Share your thoughts and let’s discuss how we can collectively advance the field.

Good luck

Karthik

15/11/24 130pm.