#221

Context:- I read a HBR Article on Mental Wellness at work and why it fails more often. It is estimated that in USA, 96 Billion $ is spent, I assume similar amount in other parts of the world. Pondering on this I wrote my personal Blog this morning in a general context. This is an extension of that.

Introduction: The Business Case for Mental Health

In today’s fast-paced, high-stakes work environment, mental health challenges are no longer a silent issue. They’ve become a significant factor influencing productivity, safety, and employee retention. Unfortunately, many organizations still shy away from addressing mental health openly, often seeing it as a personal issue rather than a core business concern. This perspective needs to change.

Mental health directly impacts operational efficiency, safety performance, and the overall well-being of the workforce. Embracing employee wellness is not just a moral imperative—it’s a strategic necessity. The time has come for organizations to integrate mental health into their operational excellence frameworks, and standards like ISO 45003 provide the blueprint to do just that.

Section 1: Acknowledging the Issue: The First Step Toward Change

Before diving into technical standards and frameworks, let’s address the fundamental issue: the stigma around mental health. For too long, mental health issues have been swept under the rug in workplaces. Leadership hesitates to acknowledge them, fearing it might reflect poorly on organizational culture.

However, this silence comes at a cost. Mental health challenges can manifest in absenteeism, presenteeism, decreased productivity, and safety incidents. The first step toward meaningful change is basic acceptance—recognizing that mental health is as critical as physical health.

Case Study: The Price of Ignorance Consider the case of a multinational company that dismissed stress and anxiety as personal issues. Over time, high turnover rates and safety incidents became regular occurrences. Only when they integrated mental health into their wellness programs did they see a 20% reduction in workplace accidents and a marked improvement in employee engagement.

Section 2: ISO 45003 – The Blueprint for Managing Psychosocial Risks***

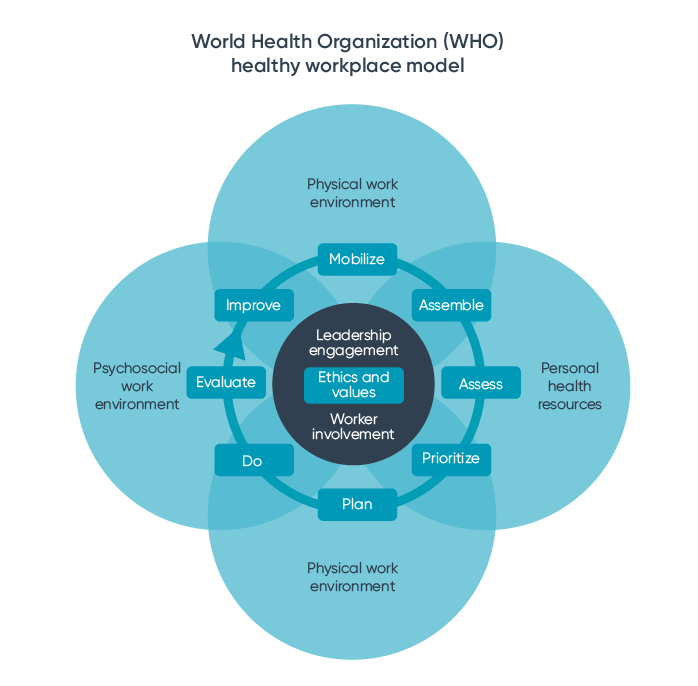

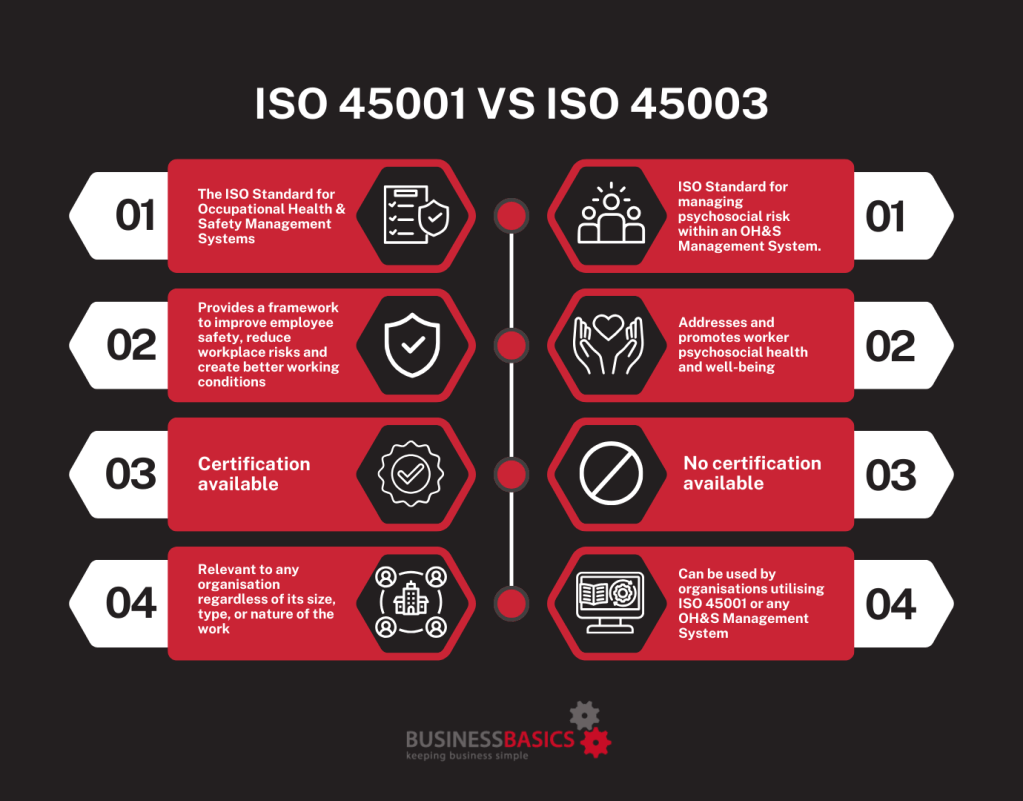

ISO 45003 is the first global standard that provides a structured approach to managing psychosocial risks in the workplace. Unlike traditional occupational health and safety frameworks, ISO 45003 recognizes that the mental well-being of employees is intrinsically linked to overall workplace safety.

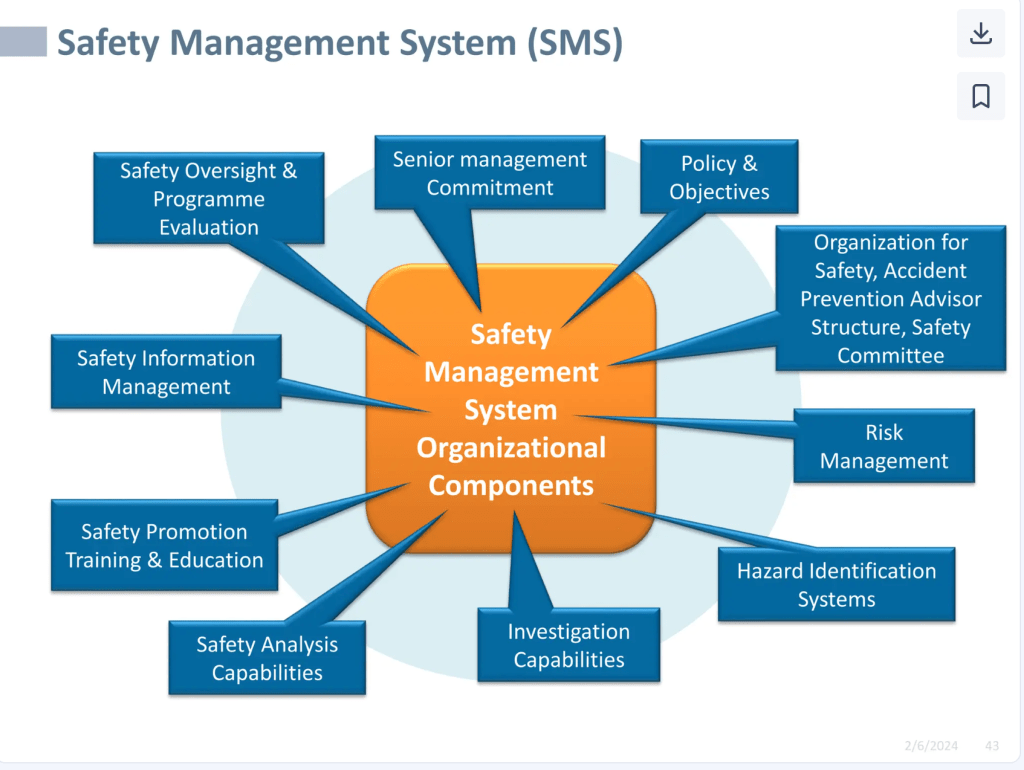

Key Components of ISO 45003:

- Risk Identification: Understanding how job design, workload, and work relationships contribute to stress and burnout.

- Risk Mitigation: Implementing strategies to address psychosocial risks, from workload adjustments to offering flexible work schedules.

- Leadership and Culture: Emphasizing the role of leaders in creating an environment where mental health issues can be openly discussed and addressed.

- Integration with ISO 45001: ISO 45003 can be integrated with existing safety management systems like ISO 45001, creating a holistic approach to managing health and safety.

Case Study: ISO 45003 in Action A global engineering firm piloted ISO 45003 in one of its high-stress operational units. By integrating mental health into its safety management system, the company reduced stress-related absenteeism by 40% and saw a significant decrease in near-miss incidents. Employees reported feeling more supported, which led to higher engagement and better overall safety performance.

Section 3: Technical Aids and Tools for Managing Mental Health

In addition to ISO 45003, organizations can utilize several technical aids to support mental health management. These tools can complement formal frameworks and provide practical, on-the-ground support for employees.

Mental Health First Aid Programs

Training employees to become mental health first responders can make a huge difference in identifying early signs of distress. Much like physical first aid, this initiative helps create a support network that can intervene before issues escalate into serious problems.

Technology-Driven Solutions

With the advent of mental wellness apps and telemedicine services, employees can access mental health support at their fingertips. Platforms like Headspace and Calm offer mindfulness training, while telemedicine options allow employees to consult professionals without leaving their workspace.

Ergonomics and Workspace Design

A poorly designed workspace can significantly contribute to stress and fatigue. Investing in ergonomic solutions, optimizing lighting, and offering quiet zones for focus and relaxation can enhance mental well-being.

Case Study: The Impact of Ergonomics on Mental Health A pharmaceutical company revamped its office layout, incorporating quiet rooms, ergonomic furniture, and natural lighting. Within six months, employee satisfaction scores improved by 30%, and reported stress levels decreased significantly. This simple redesign demonstrated how workspace influences mental health.

Section 4: Building a Wellness-Driven Organization

Addressing mental health requires more than just a few policies; it requires embedding wellness into the organization’s core values. This can only happen through top-down accountability, where leadership takes ownership of mental health initiatives and actively promotes them.

Wellness KPIs

To track the effectiveness of mental health initiatives, organizations should establish wellness KPIs, such as:

- Absenteeism Rates

- Employee Turnover

- Incident Reports Linked to Mental Stress

- Employee Engagement Scores

Training and Development

Regular mental health training for employees and management is critical. This can include stress management workshops, resilience-building sessions, and creating awareness of the resources available for support.

Case Study: Leadership Accountability in Mental Health A manufacturing giant appointed a Chief Wellness Officer to oversee the mental health and well-being of its workforce. This leadership-driven initiative resulted in a 15% reduction in safety incidents and a 25% improvement in employee retention, proving that wellness starts at the top.

Section 5: Overcoming Resistance to Mental Health Initiatives

Despite the obvious benefits, there is often resistance—both from management and employees—when it comes to implementing mental health programs. Managers may see it as an additional burden, while employees might fear being labeled as ‘weak’ for seeking help.

The Cost vs. Benefit Argument

One common objection is the perceived cost of implementing wellness programs. However, the long-term benefits far outweigh the upfront investment. Studies show that for every dollar invested in mental health initiatives, companies see a return of $4 in improved productivity, reduced absenteeism, and lower turnover rates.

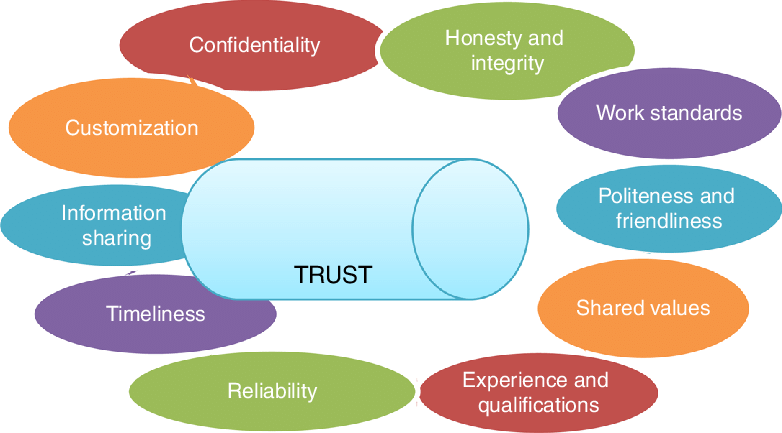

Case Study: Resistance Turned into Opportunity A tech company faced significant resistance when it first introduced mental health programs, with employees fearing stigma. By launching a series of awareness campaigns and anonymous feedback loops, the company gradually gained employee trust. Within two years, mental health resources became the most used services in their wellness portfolio, contributing to a 50% reduction in absenteeism.

Conclusion: The Road Ahead

Mental health is not a temporary trend—it’s a critical aspect of workplace safety and productivity. By embracing frameworks like ISO 45003, integrating mental health into operational excellence, and fostering a culture of openness and support, organizations can make real strides in addressing psychosocial risks.

For organizations that still hesitate, the message is clear: mental wellness is not optional—it’s a business imperative. The road ahead requires commitment, accountability, and the courage to change. But the results—improved safety, higher productivity, and a healthier workforce—are well worth the journey.

+++++++++

*** Linking ISO 45003 with ISO 45001: Building a Holistic Health and Safety Management System

ISO 45003 is designed to complement ISO 45001, which is the broader Occupational Health and Safety Management System (OHSMS) standard. While ISO 45001 covers physical safety aspects such as hazards from machinery, chemicals, and ergonomics, ISO 45003 introduces a mental and psychosocial dimension to these safety considerations.

Here’s how the two standards can be seamlessly integrated:

1. Shared Framework for Risk Management

ISO 45001 and ISO 45003 both rely on risk management frameworks. ISO 45001 primarily focuses on physical risks, while ISO 45003 deals with psychosocial risks. When an organization adopts both standards, it can create a unified risk management process that addresses all workplace hazards—whether they are physical, mental, or emotional.

For example:

- Risk Assessments: When conducting risk assessments under ISO 45001, psychosocial factors like high-pressure environments or lack of autonomy can be included, as guided by ISO 45003.

- Risk Controls: Both standards advocate for risk controls, meaning that control measures for physical hazards can be supplemented with actions to reduce mental health stressors (e.g., workload management, flexible hours).

2. Integrated Leadership and Worker Participation

Both ISO 45001 and ISO 45003 emphasize the importance of leadership involvement and worker participation. By integrating the two, organizations can ensure that both physical and mental health are treated as key leadership responsibilities.

- Leadership Commitment: Just as leadership needs to ensure a physically safe workplace (ISO 45001), they are equally responsible for ensuring a mentally healthy work environment (ISO 45003). Leadership accountability is essential in both cases.

- Employee Involvement: Both standards encourage employee involvement in safety and health decisions. In the context of ISO 45003, this means consulting employees on mental health stressors, as part of the broader health and safety conversations happening under ISO 45001.

3. Combined Health and Safety Objectives

Organizations already implementing ISO 45001 can integrate mental health objectives into their overall occupational health and safety objectives. For instance:

- Health and Safety Policies: By incorporating psychosocial risks into the organization’s safety policies, the company can present a unified front on both physical and mental health.

- KPIs and Monitoring: Both standards stress the importance of performance monitoring. Mental health indicators—such as absenteeism, stress-related incidents, or employee satisfaction—can be tracked alongside physical health and safety metrics.

4. Common Processes for Incident Reporting and Investigation

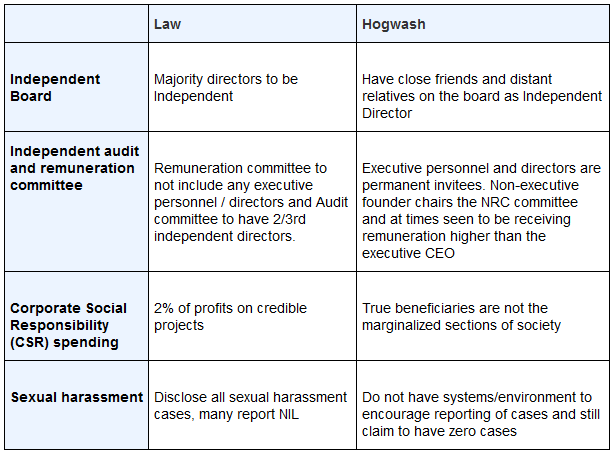

One of the critical links between ISO 45001 and ISO 45003 is the incident reporting and investigation process. Both standards encourage a culture of transparency and accountability in reporting health and safety issues.

- Under ISO 45001, incidents like injuries or near-misses are reported and investigated.

- Under ISO 45003, similar mechanisms can be applied to report mental health-related incidents (e.g., workplace bullying, burnout, or stress-related issues).

By creating a single reporting system, organizations can address both physical and psychosocial incidents effectively. This allows for a holistic investigation process, where physical and mental health factors are examined as potential root causes of accidents or absenteeism.

5. Integration into the PDCA Cycle

ISO standards follow the Plan-Do-Check-Act (PDCA) cycle, and ISO 45003 can be seamlessly integrated into the PDCA approach used for ISO 45001:

- Plan: During the planning phase, organizations can identify both physical and psychosocial risks, setting objectives for improving mental and physical safety.

- Do: Implement controls that address both safety hazards and mental health risks. This can include physical safety training as well as mental health awareness programs.

- Check: Monitor the effectiveness of safety measures, both physical and psychosocial, through audits, employee feedback, and incident reports.

- Act: Take corrective actions based on insights from monitoring, addressing gaps in both physical safety and mental health support systems.

6. Training and Awareness Programs

ISO 45001 emphasizes the need for ongoing safety training for employees. With ISO 45003, this can be extended to include mental health awareness and resilience training, creating a more comprehensive training program.

For instance:

- Physical and Mental Health Toolbox Talks: Rather than only focusing on physical hazards in safety meetings or toolbox talks, organizations can introduce mental health topics, encouraging open discussions about stress management, burnout, or workload management.

Final Thoughts on Integration

By combining ISO 45001 and ISO 45003, organizations can create a truly comprehensive health and safety management system. This integration ensures that employees’ physical and mental well-being are both addressed, leading to a safer, healthier, and more productive workplace.

The key takeaway is that managing health and safety isn’t just about preventing injuries—it’s about creating a work environment where employees can thrive both physically and mentally.

Karthik

19/10/2024, 1800 Hrs.