#261

Disclosure:- I am yet to come across an Indian site where this theme worked. I would therefore boldy include any level of maturity sites in India.

Safety sounds simple, right? Tell everyone on the shop floor they’re responsible for it, and boom—problem solved. Everyone looks out for each other, hazards get spotted, and incidents drop. Except, in reality, especially at manufacturing sites with low safety maturity, this well-meaning mantra can create more problems than it solves. Here’s why pushing “safety is everyone’s responsibility” too early might be a risky move—and what needs to come first.

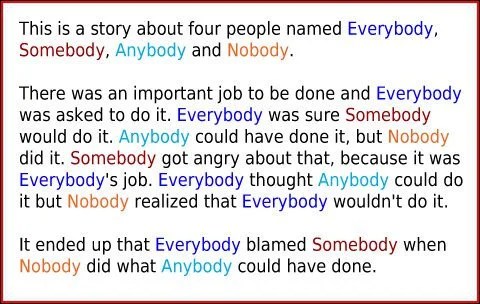

1. The “Someone Else Will Handle It” Trap

Picture this: a group of workers is tackling a task with hidden hazards—say, a machine with a tricky lockout-tagout process or a cluttered walkway near heavy equipment. When everyone’s told they’re responsible for safety, it’s easy for some to assume someone else will step up. Diffusion of responsibility kicks in. No one wants to be the nag, and no one takes ownership. End result? That loose guardrail or unmarked spill stays ignored until it’s too late. In low-maturity sites, where proactive habits aren’t ingrained, this laissez-faire vibe can quietly brew at-risk situations.

2. Monkey See, Monkey Do—But With Hazards

Here’s another practical snag: people mimic what they see. If a site hasn’t done proper risk assessments—especially for unplanned or new activities—workers might copy whatever’s happening around them. Say a newbie sees a veteran skip a safety step because “it’s always been done this way.” Without clear guidance, that shortcut spreads like wildfire. In a low-maturity setup, where hazard awareness is shaky and documentation is spotty, this herd mentality can turn a small oversight into a full-blown incident. Everyone being “responsible” doesn’t help if no one knows what right looks like.

3. Supervisors Are the Linchpin, Not the Crowd

Let’s be real—hazardous situations on a manufacturing floor can shift fast. A chemical spill, a jammed conveyor, a power surge—these aren’t static problems. Supervisors, with their experience and bird’s-eye view, are best equipped to analyze what’s going on and call the shots. Expecting every worker to independently assess and act in chaotic, ever-changing conditions is a tall order, especially at sites where safety training is basic or inconsistent. Without that top-down clarity, “everyone’s responsible” just turns into “everyone’s guessing.”

4. It’s a Logistics Nightmare Without Maturity

Making safety a shared responsibility sounds noble, but it demands serious planning, coordination, and follow-through—stuff low-maturity sites often lack. You need solid communication channels, regular training, clear roles, and a culture that rewards vigilance. Without that backbone, the idea collapses under its own weight. Workers get confused, priorities clash, and safety becomes a buzzword instead of a practice. Low-maturity sites are still figuring out the basics—adding a complex, everyone-pitches-in approach is like handing a toddler a Rubik’s Cube.

5. The Missing Foundation: Systems and Engineering First

Here’s the kicker: safety doesn’t start with people—it starts with systems. A robust Safety Management System (SMS), built on engineering excellence and thorough risk assessments, is the real game-changer. Think proper machine guarding, well-mapped hazard controls, and legal compliance baked into the process. Only after that foundation is laid can you layer on the “everyone’s responsible” mindset. It’s like building a house—you don’t hang curtains before pouring the concrete. At low-maturity sites, jumping straight to shared responsibility skips the critical step of giving workers a safe environment to take ownership of.

The Path Forward: Maturity Before Mindset

So, what’s the fix? Start with the nuts and bolts—engineering controls, risk assessments, and a functioning SMS. Train supervisors to lead, not just react. Build a culture where safety isn’t a slogan but a habit, backed by clear processes. Once that maturity takes root, then you can roll out “safety is everyone’s responsibility” as the next step—not the starting line. It’s not about ditching the idea altogether; it’s about timing it right. Low-maturity sites need structure first, empowerment second.

Bonus Point: Accountability Gaps

One more thing to chew on: when everyone’s responsible, no one’s accountable. If an incident happens, who takes the hit? In a low-maturity site with fuzzy roles, it’s easy for blame to bounce around—or worse, get buried. A strong SMS ties accountability to specific actions and people, which keeps the system honest. Without that, the “everyone’s job” approach can erode trust and let sloppy habits slide.

What do you think? Comment below.

Karthik

28/3/25 1130am.