#216

Personal Update:- I am suffering from Back Spasm issues, and advised bed rest for a considerable time. My blog therefore will be sparodic.

In today’s fast-paced industrial world, organizations are constantly evolving. Yet, safety continues to be a major concern across industries, particularly in India, where compliance often takes precedence over proactive safety culture. However, safety is not just about ticking boxes on an Excel sheet or meeting compliance standards. It’s about creating a workplace where everyone learns, adapts, and improves continuously. This is where the concept of a learning organization comes in, with an emphasis on safety, productivity, and, importantly, the human touch with an ingradient of “TRUST”

What is a Learning Organization?

A learning organization is one that fosters a culture of continuous improvement. It encourages employees at all levels to learn from their experiences, from successes and failures alike, and to apply that learning to future tasks. In a safety context, this means an organization that doesn’t just look at accidents or near misses as isolated incidents but as opportunities to understand root causes and prevent future risks.

For example, in one of my past projects, we had a near-miss involving a chemical spill in a manufacturing unit. Instead of simply fixing the immediate issue and moving on, we brought together a team across departments—operators, engineers, safety officers—to analyze what went wrong, what gaps in communication existed, and how the system could be improved. This collaborative learning led to better communication channels and updated safety protocols, which ultimately resulted in smoother operations and higher productivity.

Continuous Learning for Safety Improvement

Learning organizations place high value on knowledge sharing and constant improvement. In the Indian industrial context, many companies rely heavily on outdated systems of incident reporting and compliance-based safety audits. While compliance is necessary, it’s not enough. To truly make a difference in safety, organizations must embrace a learning mindset.

Take the case of Tata Steel, which over the years has developed a strong safety culture by continuously investing in employee training and leadership development. Tata Steel has not only met regulatory compliance but also gone beyond by fostering a culture where every incident is a learning opportunity. Their safety records have improved dramatically over the past decade, with fewer incidents, lower absenteeism, and higher employee morale.

The Human Touch: Key to Safety Culture

One of the biggest challenges in India is making safety personal. We often see safety measures as rules imposed from the top rather than as a shared responsibility. Leaders must cultivate an environment where employees feel safe to speak up, share concerns, and learn from mistakes without fear of punishment. This is where empathy and leadership come in.

Imagine a scenario where an employee feels hesitant to report a safety issue because they fear it may result in disciplinary action. In a learning organization, leaders encourage open communication and treat every report—be it a near-miss or an unsafe practice—as valuable feedback for improvement. By showing genuine care for employee well-being, leaders can make safety a part of everyday work, not just something that happens during audits or inspections.

In my own career, I’ve seen how simple, human gestures can make a big difference. I once had a manager who would personally check on the safety of workers during shift changes. His presence, concern, and willingness to listen made employees feel valued, and they became more proactive in identifying safety hazards. It wasn’t just about protocols; it was about creating trust and making safety a human concern, not just a corporate one.

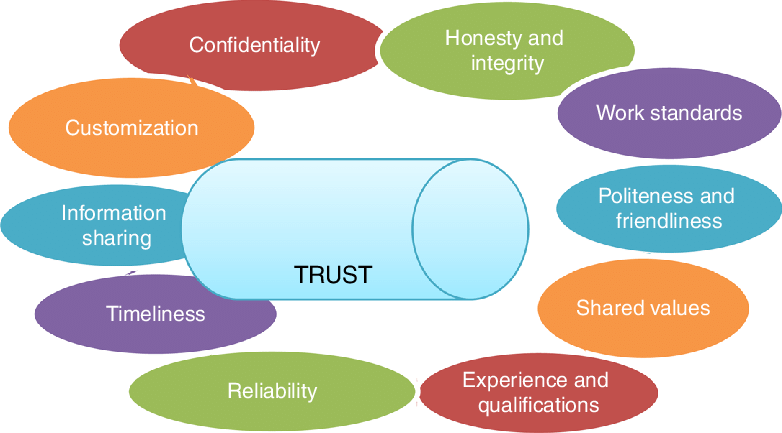

The Role of Trust in Building a Learning Organization

One of the most fundamental aspects of fostering a strong safety culture and a learning organization is trust. Without trust, even the most well-designed safety programs or learning initiatives can fall flat. In many modern workplaces, trust between employees and management is fragile or even absent. This lack of trust creates barriers, both for safety improvements and for productivity gains.

Why Trust Matters

Trust is the foundation upon which open communication, honest feedback, and shared responsibility are built. If employees don’t trust their leaders or feel that their voices won’t be heard, they are unlikely to report safety concerns, share ideas, or admit mistakes. This not only affects the safety of the workplace but also stifles learning and growth, which are essential for any organization’s long-term success.

For example, in a high-risk environment such as a manufacturing plant, workers who don’t trust that management will take their safety concerns seriously may choose not to report a potential hazard. The result? A safety issue that could have been addressed early escalates into a full-blown incident. This damages productivity, incurs costs, and can harm employees. If trust is present, employees feel empowered to speak up, knowing their concerns will be addressed without fear of retribution.

How Lack of Trust Affects Safety and Productivity

In my experience, one of the biggest challenges in the Indian industrial setting is a lack of trust between different levels of an organization. Workers often believe that management is more focused on production targets than their well-being. This disconnect creates a climate of fear rather than one of shared responsibility. If a worker feels that reporting an unsafe condition might lead to disciplinary action or being blamed for slowing down production, they’re less likely to raise the issue.

This lack of trust not only puts safety at risk but also hinders productivity. When employees don’t feel secure, they are less engaged, and disengaged employees do not perform at their best. Moreover, a lack of trust leads to poor communication, which directly impacts learning within the organization. Teams that do not trust one another tend to work in silos, preventing the sharing of knowledge and experiences that are crucial for continuous improvement.

Building Trust for a Safer, More Productive Workplace

Building trust takes time, but it is the key to a successful safety culture and a productive learning environment. Here’s how leaders can foster trust:

- Transparent Communication: Leaders need to be transparent with their employees, not just about safety protocols, but also about the broader goals of the organization. When employees understand the ‘why’ behind safety measures and see them as part of a larger strategy for their own well-being, they are more likely to trust management and engage with safety initiatives.

- Lead by Example: Trust is earned, not demanded. Leaders must demonstrate their commitment to safety by walking the talk. When employees see that their leaders are genuinely concerned about their safety and not just compliance, trust begins to build.

- Accountability Without Blame: In a learning organization, mistakes are opportunities for growth, not grounds for punishment. When employees trust that they won’t be blamed or reprimanded for reporting incidents or raising concerns, they are far more likely to speak up. Leaders need to create an environment where accountability is shared, and every incident is treated as a learning moment, not a blame game.

- Involve Employees in Decision-Making: Trust is a two-way street. By involving employees in safety decisions and problem-solving, organizations can foster a sense of ownership and responsibility. When workers are part of the solution, they are more invested in maintaining a safe workplace.

- Recognition and Reward: A simple yet effective way to build trust is to recognize and reward employees who demonstrate a commitment to safety and continuous learning. Recognition shows that leaders value safety as much as productivity, reinforcing the importance of trust and shared goals.

Trust as the Key to Organizational Learning

In learning organizations, trust is the glue that holds everything together. When there is trust, employees are not afraid to take risks, share ideas, or admit when they don’t know something. This openness is what fuels learning and innovation. Without trust, however, fear and rigidity take over, stifling creativity and preventing the organization from growing.

In the context of safety, trust enables employees to engage fully in safety training and initiatives, knowing that their contributions matter. It allows for open discussions about past incidents and future risks, and fosters a culture where safety is everyone’s responsibility, not just the safety department’s.

Leadership’s Role in a Learning Organization

Leaders play a crucial role in shaping a learning organization. In India, we often see a hierarchical approach to management, where safety decisions come from the top down. But in a learning organization, leadership is about fostering an environment where learning happens at every level. It’s about moving away from blame and focusing on continuous improvement.

Take the example of Mahindra & Mahindra, which has embraced a learning culture to enhance both safety and productivity. The company invests heavily in leadership training, ensuring that managers and team leaders understand the importance of safety and create open communication channels with their teams. This approach has led to not only safer working environments but also more engaged employees and improved operational efficiency.

Connecting Safety to Productivity

One of the most overlooked aspects of safety is its direct link to productivity. When employees feel safe, they work better. When safety protocols are streamlined and based on real-time learning, operations run smoother. In contrast, when safety is merely a compliance exercise, it often leads to inefficiencies, higher accident rates, and decreased morale.

I once worked with a plant in my consulting,where safety was viewed as a burden—something that slowed down work. After a safety audit revealed major gaps, we shifted focus to creating a learning-based safety culture. Over the next year, not only did accidents reduce, but productivity shot up by 20%. Workers felt more confident, downtime decreased, and the entire organization benefitted from this shift.

Practical Takeaways for Indian Organizations

- Promote a Learning Culture: Encourage employees to share their experiences and learn from incidents without fear of blame. Use every incident as a learning opportunity.

- Engage Leadership: Leaders must actively participate in safety initiatives, showing that safety is a priority from the top down. Their engagement will inspire employees to take safety seriously.

- Human Touch Matters: Safety is about people. Building trust and empathy within the workforce makes safety measures more relatable and effective.

- Invest in Continuous Training: Regularly train employees, not just on protocols but on understanding risks and the importance of safety to their own lives.

- Link Safety to Productivity: A safe workplace is a productive workplace. Show employees how safety contributes to smoother operations and personal well-being.

In conclusion, safety isn’t just about following rules. It’s about creating an organization that learns from every experience, fosters a culture of care, Trust, Human touch, and empathy, and ties safety directly to productivity. As we move forward in India’s industrial landscape, adopting a learning mindset with a human touch will not only enhance safety but also improve overall business performance.

God Bless.

Karthik

3rd October 2024. 1600 Hrs.